Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Eccentric Reducers

Features standards and products of our Butt-Welding Eccentric Reducers:

Features of Butt-Welding Eccentric Reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Eccentric Reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Eccentric Reducers:

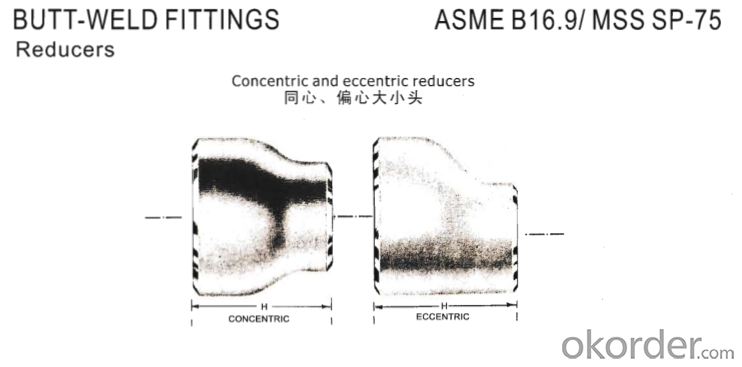

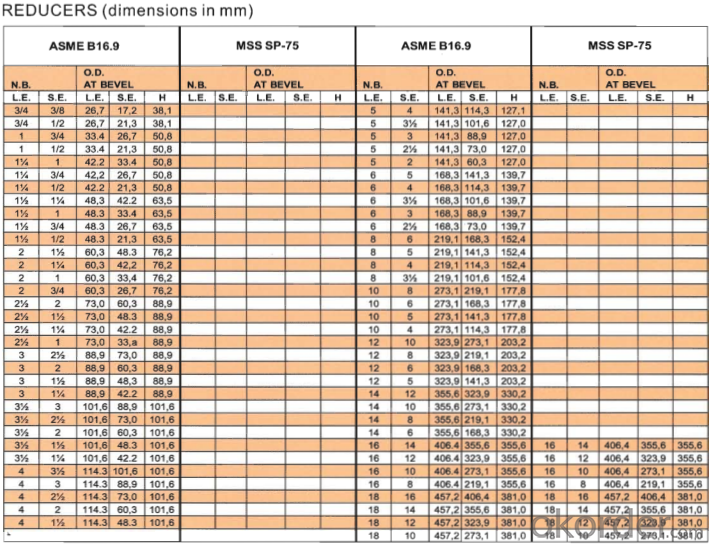

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Eccentric Reducers:

Packing of Butt-Welding Eccentric Reducers:

FAQ of Butt-Welding Eccentric Reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I would like to know where to find on the Web a bicycle helmet either with a built-in face shield (covering the actual eyes and face, not just a peak like the brim of a baseball cap), or a separate face shield that you can attach to a helmet to cover your eyes and face.Try not to limit your focus to visors on the time trial style bicycle helmets. No references to motorcycle-only helmets please! I am referring to bicycle helmets.Please link to pictures!

- These fittings come in numerous materials and pressure ratings. You need to specify what exactly you are interested in. You can then do a web search for the information you need.

- Q:can you tell me in each steps

- a copper pipe bushing is used to join two pieces of pipe that are different diameter's such as 3/4 and 1/2 pipe,normaly one uses the outside of the bushing to go inside the female end of a fitting and the insid of the bushing is drilled to accept the pipe itself. A coupler,or coupling is used in much the same way except it can be used to join 2 pieces of pipe of the same diamater or different diamaters and the pipe ends fit inside the coupling.

- Q:Could anyone cite me the exact law and perhaps the reasoning behind it?

- those 3 sharp beats mean the batterly is low, the 9volt batter can last a while on those fire alarms but try changing the batter. and the fuse is the apartments responsibility. any thing major where you need to call a repair man out should be at the apartments expense. its a liabilty thing.

- Q:fender system one guitar tremolo lock collar?

- Probably look at it in amazment, then lay down my laptop and walk around the house to see where it was coming from. Not exactly the safest procedure is it?

- Q:Groundhog fire alarm Rottweiler and a husky

- If you have a car dealer nearby who sells your daughters brand car, they have a dealer only master wheel key set. That's the good news. The bad news is you will need to have your car towed there as they trust no one with their master locking key set. They will remove your tire and replace the locking lug with a non-locking one until the company who made her original mails you a new one. What has to happen is the following: Upon your proof of ownership of the vehicle your dealer sends a computerized code directly off your VIN . The manufacturer springs this code to the company who made the original wheel lock. You give the lock company a credit card and you will have a new wheel lock within a week.

- Q:Puvc pipe joint leakage how to do?

- That will help you do better plugging without changing the new foundation. But the cost is several times higher than the new one. Ha-ha

- Q:Could somebody help me ask Oda why Jango's disk didn't split Luffy's head into two?

- Go Put in your state and they will give you more contact information.

- Q:Any Storage systems or anything?

- The flare connection uses pressure to keep the seal. Pipe dope can defeat that by providing a soft barrier in between the metal thus allowing a greater chance for a leak, not to mention it can clog the orifice. Did you know that flex lines are a 1(one) time use item? If disconnected for any reason after the initial install it must be replaced Read the tag that is attached to it.

- Q:Re series 24 degrees cone O ring seal pipe joint joint, corresponding to the national standard number is?

- There are many kinds of pipe joints, and the commonly used pipe joints can be divided into two kinds: hard pipe joint and hose joint. If in accordance with the connection pipe joints and pipe points, hard tube joint with flared type, sleeve type and welding type three, hose connector is mainly buckling type hose connector.In hydraulic system, the connection way of pipe and pipe joint is different. The screw is used to connect screw thread. The taper thread is screwed on its own vertebral body and is sealed with polytetrafluoroethylene and other substances. It is mainly used in the hydraulic system of medium and low pressure. The sealing effect of fine thread is very good, is often used in high pressure system, but it requires the use of combination washer or O ring to end closed, sometimes used copper gaskets, it is suitable for the pipe connecting pipe wall is thick, the main part of a joint body, and take over nut. When in use, the joint body is embedded in the target, and the end face is sealed by using the gasket mentioned in the front; the rubber seal is used between the joint body and the connecting pipe, and sometimes the spherical sealing method is adopted.

- Q:The hydraulic pipe fittings how to distinguish the British, American, metric!

- Metric threads are represented by pitch, and American and English threads are expressed in thread per inch;Metric thread is 60 degrees equilateral tooth type, thread is isosceles 55 degree tooth type, thread is isosceles 60 degree tooth type;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords