Solid grey color wooden plastic composite wpc manufactured outdoor decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solid grey color wooden plastic composite wpc manufactured outdoor decking

一.Product Description:

.

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

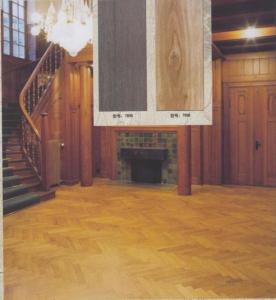

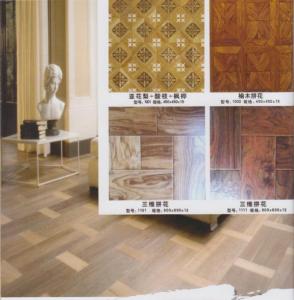

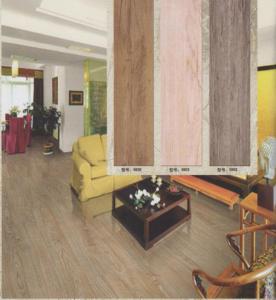

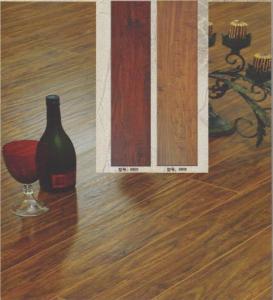

四. More picture for your reference

- Q:i'd like to level them from the floor joists, not adding another floor over the existing ones

- Assuming you have a basement with a good floor, (I did) I used 6, 4 in I beams 10 ft long. That is all I could handle by my self. 13 screw jacks. The 7 ft ones. I spent the biggest part of a year, I would screw us the lowest ones till the old house started creaking and popping. Wait for a time, from a week to a month and go after it again. Took about a year. My house was 28 by 40, 2 story. As I leveled the down stairs floor the up stairs went along. My biggest problem was finding different doors. Over the years people had cut off the doors on an angle so they would open and shut. With every thing level and plum, they did not suit my wife.

- Q:We might install Duraceramic flooring by Congoleum in our kitchen, utility room, family room and office. Looking for comments from those with experience with this type of flooring.

- I love my Duraceramic floor. I installed it myself and it was easy!

- Q:I pulled up all the carpet in my bedroom, and some areas in the hardwood floor is darker then some other places. What can I do to make the floor bright again?

- Sand it down and refinish it (stain, polyurethane). You can rent a machine and do it yourself or pay someone to do it. You could also put a throw rug over it if you can't refinish it.

- Q:We never went trough them but got an assignment that involves it, I'm guessing point of this is to learn to research on your own. And I did but one of the questions is to prove floor(x)+floor(-x). I know it's always -1 unless x =N but how do I prove it?

- Remember x can describe as integer part y and decimal part .ddddd or y.dddd the floor of y.dddd and -y.dddddd so floor of (y.dddd) is y (the next smaller number ) the floor of (-y.ddddd) = -y - 1 (the next smaller number) so along as .dddd is not zero . for positive x , floor(y.ddddd) = y for negative x, floor(-y.dddd) = -y - 1 so floor(x) + floor(-x) = y + (-y -1) = -1 However , when x is a whole number you have y + (-y) = 0

- Q:Would you like to be able to shop with stone flooring?

- No problem, but if there is a choice, for a long time, or for a material it

- Q:Self-heating floor energy saving? Power consumption?

- Not only, but the heating stage of power consumption, to achieve a balance value, it is very power, and one hundred square meters in January about five or six hundred, and all-weather. You can choose the North American gold, the southwest region also goods

- Q:Is the elephant of the solid wood flooring, may be installed when the sliding door of the bucket of spring and dagger tigers Tong Tong Quang, sliding door accidentally scraped to the solid wood flooring, a little conspicuous, the color of the surface of the floor has been scraped, and now It seems to be a piece of white, is already seen to see the wood, and what simple way to repair it? More

- Teach you a way to buy a little better floor wax with color fine tune and the color of the floor similar to the color and then waxing, the effect will be bad not bad marks, you can DIY, the method for .. with almost the color of the oily microphone Or crayons painted, and then gently coated with your fingers, so that the coating should not be so obvious; scratches if deep, to the building materials hardware line, buy wood flooring bucket bucket spring dagger mazhi Tong Changkun Cracker Or with the wood chips + close to the wood floor color of the water-based silicone) into the depression, and then smoothed. Of course, repair up to see or there are traces (just like the car scratches repair DIY). ● If it is really serious or the effect of repair is not satisfied, you must find a professional wood flooring company to deal with, the replacement will be damaged serious wooden floor dug up, and then replace the new; the vast majority of need to scraping Around the bad wooden floor, together with the wood flooring that has not been worn, it has been dug together (because the wooden floor and the wood floor have a mouth joint, a single wooden floor is difficult to practice). ● If it is solid wood flooring, you can also ask the master to scratch, re-polished paint, but this practice does not apply to ultra-wear-resistant or island-type floor.

- Q:I have cleaned, degreased, and filled cracks in the garage floor (let cure 10 days). It has been powerwashed and swept (you could eat off of it now). I mixed the etching solution according to the directions and applied to pre moistened garage floor. The directions state that if the solution does not fizz the floor is sealed and needs further prep and that if it does fizz it will do so for 4-5 minutes. I applied the etching solution and it did fizz but for a very short time (Less than 1 min). Also, the floor does not feel very rough...in fact, I can't tell any difference from now to when there was nothing done besides cleaning. Any suggestions from someone that has used this product or has knowledge of etching would be much appreciated.

- Rocksolid Floor

- Q:Our house from today to start the floor, to shop one and a half days, no rain today, you can weather forecast that the world heavy rain, how do? Can you continue to shop? Can the shop be stopped? And foolishness to convince the ghosts of the feathers and astringency and weather forecast that the world after the thunderstorms, the day after tomorrow are sunny. The The We bought the Yongji floor, the Louvre series. The Question added: ok, today only 3 hours in the morning rain, afternoon are cloudy no rain, thank you for the answer more

- It is best not to shop, rainy day humidity, easy to cause the floor to shrink and expansion, and so fine sunny shop better. I wish you a pleasant decoration

- Q:Ordinary tiles can withstand 120 degrees Celsius sustained high temperature it

- 120 degrees is not high temperature, the general tile can withstand more than 1000 degrees of high temperature, polished tiles can withstand more than 1600 degrees.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solid grey color wooden plastic composite wpc manufactured outdoor decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products