Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Double Suction Split Casing Water Pump for Pump Station

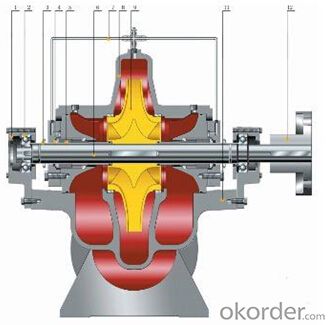

1.Structure of Single Stage Double Suction Split Casing Water Pump Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the Single Stage Double Suction Split Casing Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Single Stage Double Suction Split Casing Water Pump Images

4. Single Stage Double Suction Split Casing Water Pump Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q:Hi I just brought a chrysler sebring V6 that needs a water pump. I found a water pump on OKorder for only $30 and it only had 900 miles and it works great. Should I buy it?

- Yes. Most salvage yards will give a 30 day warranty. It's worth a try. Make sure when you replace the water pump you also replace the timing belt. The reason is, in order to get to the water pump the parts all have to be removed so you might as well replace it when the mechanic is in there. Your timing belt could go out next week and you'd have to pay all of the labor again.

- Q:How do the water pump work please till me water pump mechanism?

- Water pumps can be positive displacement or impeller type. Either of these increases the pressure of the water and so can move or lift the water. Centrifugal is an impeller type where a sort of fan blows the water. If the fan stops the water can flow back. You'll need to prime these if they get dry. Fishtanks might use this. Positive displacement means that the water is pushed by some sort of piston. Diaphragm pumps are positive displacement and useful if you don't want the water to run back. Also you won't need to prime it because won't drop the water out when it stops. I'm not sure where hydraulic ram type pumps come into this scheme but they rely on the inertia of moving water to generate high pressure pulses to pump water.

- Q:What is the difference between a High Flow Water Pump, Heavy Duty Water Pump or and Electrical Water Pump for a street rod? I have a 77 Camaro with around 410hp with the factory A/C. The Camaro is stock as body, frame and interior. I want to enjoy the car vs racing it. I would like to go on trips to visit family out of town which is around 300 miles and be able to drive the car with out having over heating problems.

- High flow is just that. It flows more coolant than stock Heavy duty is one with alittle bigger impeller shaft and disk Elec. water pump runs on 12 volts, no belt You should not use an elec water pump on a street car, those flows less coolant and do not last as long. I recommed a Milidon high flow water pump for yours. I'm running one of those, a summit 31x19 alum rad, and a ford turus 2 speed elec. fan on a 500 HP engine in a camaro and never have any cooling probs.. Even on 6 hour one way non stop trip in 90-100* weather during the summer

- Q:it just go? I was told that my water pump had leaked at least for awhile before it went and if it had been in the garage someone competent should have noticed it. Then other people have told me No it just goes.whats accurate?

- Check the water-pump weep hole under the input shaft casting. You have to look underneath the pump while the car is on jack-stands or plastic ramps. The weep-hole will show the color of the coolant if it's leaking. It will leak at a higher rate with the engine is running when the cooling system is under pressure than when the car is sitting and the engine is cold. Any trusted private mechanic or new car dealer can see a water-pump leak if you can't lift the car safely to crawl underneath.

- Q:The role of impeller in water pump

- The impeller is driven by electric motor rotation, the middle impeller creates a vacuum to vacuum at the inflow of water will be (on the surface water is continuously sucked into the impeller), then the water through the high-speed rotation of the impeller of the water discharge, play a promoting role in water.

- Q:i have a 2003 dodge neon and my thermostat keeps rising to the highes level setting off the indicator (its not broken) i did have a leak in the raiditor and it was very notice able..after pacthing is up there was noproblem till yesterday now the thermostat keeps rising i admit the is very little antifreeze in ther and the rest is water but the is the same mixture tha was in the care that it was rinning off for the last three minths i cannot seem to keep the thermostat down my raiditor is in nee of repair but i m wondering if its the water pump does the water pum help regulate engine temperture? ther are no ivsible leaks and no drippiage could it be that i just need to put antifreeze or could it be the water pump or a broken raidiator? help i will give points for best anwser but really i just need help!

- All water pumps have what is called a weep hole and when the water pump seal goes out antifreeze will come out of the weep hole and stain the surrounding area. If your radiator was leaking its probably best to replace it and never use any of those stop leak products. They are more of an emergency repair to get you home until you can get the leak fixed properly. Have you changed the thermostat. When you put in antifreeze do you mix it with tap water or distilled. Distilled is always the best as tap water will leave mineral deposits inside your cooling system. Also on the thermostat they make what is called a fail open thermostat that allows for coolant flow even if the thermostat fails where as a regular thermostat fails in the closed position and will cause overheating. Always run at least a 50/50 mixture of antifreeze and distilled water because it not only protects from freezing but raises the boiling temperature as well. Good luck.

- Q:Had house power washed today and need my water to work again!

- I am assuming that the breaker for your water pump is in a disconnect box on the exterior of your house. If the disconnect is wired to code the disconnect would be fed with a line that also has breaker in your main panel. If this is the case the first thing you should do is identify this breaker and turn it off. Don't go by any labeling on the panel. Use a tester to make sure power is completely off in the disconnect.If power is off you can then pull the breaker out and dry it off. You can also dry the enclosure with a towel. When everything is dry reinstall the breaker and turn power back on in main panel. If it still pops in disconnect, it would be wise just to buy a new breaker , they are not that expensive. Not necessary to start using cleaning sprays.This procedure should solve your problem if everything has been wired to code. If you are not sure about anything I have described, please call a professional. Good luck.

- Q:Yesterday morning I was looking under my hood and I noticed that I was leaking water. It looked like the leak was coming from the water pump.I had to get to work, which is close by so I topped off the radiator and went to work. When I got to work I looked under the car and saw no leaking. I figured the radiator had ran dry although the car hadn't overheated, After work I started to fill the radiator to get home. I saw that I had leaked a little fluid but not much. I topped it off and picked up my son then went home. No overheating. No leaking. Today I've ran several errands and I've had no problems. What do you think was going on with my water pump yesterday?

- Sounds like a leaky gasket on pump...A suggestion : Remove lower raditor hose let old coolant drain..Maybe replace thermostat.. Refill with fresh Prestone...Check water pump bolts for tightness . Replace any hoses etc... if needed

- Q:My truck turned off by itself and a bunch of steam and smoke came out and my radiator was dry. To keep it running i had to have the engine revved and at a stop sign hold the brake down. and slightly press. I'm assuming its the water pump however. It started yesterday as the colder weather started. What my question is what do you think it is and if you have experience with water pumps, how hard is it to replace i found one for $14

- that don,t sound like the water pump. if it was the pump then it would overheat and leak out. check to see where it,s leaking at. if it,s leaking from the pump then it will have to be changed even though it still might not help it to idle. it,s not really that hard to change the pump on a 351W . the hardest part is getting into it. you might have to remover some stuff so you can work. the belt and water pump pulley will have to come off and the fan but that should let you into the bolts.

- Q:replaced water pump and thermostat, flushed, opened bleeder valve had long life red colored original coolant, no visible leaks obstruction, when became hot on highway, accelerated quickly and temp back down to norm, eventually after 3hrs driving o.heated stopped and got towed home, new water pumps fins/pulley not turning as freely as old one, no leak out of inspection hole, hoses good shape.2001 2.2l ohv sunfire, air cond.

- get your vehicle up to operating temps and runs your hand along the core of the radiator from top to bottom. If it's cold at the bottom and hot at the top, it's plugged... Also I see where you bleed the system, might wanna check it again... air pockets are stubborn... Last but not least, have a C.O. test performed at a local radiator/automotive shop... This will tell you if you have a blown head gasket

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords