SCB9-30-2500-10 Epoxy resin dry-type power transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production introduction

The dry-type transformers are casted with epoxyresin,which are made of high quality materials by means of a strict process with advanced production and testing devices.The product features high reliability and long service life.In accordance with different operation environment,it can be equipped with different protection casings or without casing.It can replace the oil-immersed transformer and be used in the high buildings,business centers,airports,tunnels,chemical plants,nuclear power stations and watercrafts ect.

Normal service conditions

1)Altitude should not be over 1000m:indoor type

2)Highest ambient temperature should not over:+40oC;Highest daily average should not over temperature:+30oC

3)Highest annual average temperature should not over +20oC,lowest temperature should not below -5oC.We can provide transformer operated in special conditions according to user's requirement.

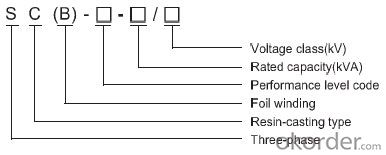

Model designation

Applicable standards

GB6450-1986 Dry-type power transformer

GB4208-1993 Casing protection grade(IP code)

GB/T10228-1997 Technical parameters and requirements for dry-type power transformer

Performance characteristics

1.The product is safe,fire-proof,pollution free,and can be used in the load center directly.

2.High mechanical strength,strong shour-circuit proof capacity,small partial discharge,excellent thermal stability,high reliability,and long service life.

3.Low loss,low noise,energy saving and maintenance free.

4.Excellent heat dissipation,great overload capacity and a large operating capacity is available when ONAF is applied.

5.Good humidity resistance,it's suitable for operating in the highly humid and harsh environment.

6.An intelligent signal and temperature control system is adopted,which can automatically monitor and display all working temperature of the three-phase windings.The blowing fan can give an alarm,switch on and off automatically and conduct tripping operation to protect the transformer.

7.Dur to the structure is compact and weight is light,it can save space and decrease the cost of installation.

Notes for placing orders

Transformer type:rated capacity kVA

Number of phases:three-phase single-phase

High voltage: KV/Low voltage:KV

Frequency:50HZ 60HZ

Tapping range:±4×2.5% ±3×2.5% other

Connection group:Yyn0 Dyn11 other

Impedance voltage:4% 6% other

Cooling method: ONAN ONAF

Protecting grade of outer casing:IP00 IP20 IP30 other

Method of incoming and outgoing line:

1.Incoming line to lower part and outgoing line from upper part

2.Incoming line to upper part and outgoing line form upper part

3.Incoming line to upper part and outgoing line form side part

- Q:1000KVA transformer no-load loss is how much?

- No-load loss is 1% of the rated capacity of the transformer, then 10KVA per hour. A year down about the loss is 87600KVA.

- Q:"A transformer ratio is 110/11, then it is" "A transformer ratio of 110 / 10.5, it is" "A transformer ratio of 121 / 10.5, it is"

- High pressure to low pressure is the buck, and vice versa is boosted. That is, the input transformer is a high voltage, the output is a low voltage is a low voltage.

- Q:Three-phase three-winding transformer high-pressure medium-pressure low pressure is what it means

- Hello! Transformer high voltage, medium pressure, low voltage, respectively, refers to the three groups of winding (rated) voltage level. For example: 220kV voltage level of the transformer: the 220kV high voltage side, 110kV pressure side, 10kV low voltage side of the three groups of voltage levels of the composition. Depending on the needs of the manufacturer, manufacturers may also be required to produce windings for other voltage classes. Such as: by the 220kV high voltage side, 35kV in the pressure side, 10kV low voltage side of the three groups of voltage levels of the composition. 500kV voltage level of the transformer: generally by the 500kV high voltage side, 220kV medium voltage side, 35kV low voltage side of the three groups of the composition of the voltage level winding.

- Q:Transformer turns around the number and how much V is calculated

- Transformer turns around the number and how many V calculation method: 1. Find the number of turns per volt: Number of turns per revolution = 55 / core cross section For example, the core section = 3.5 ╳ 1.6 = 5.6 square centimeters Therefore, the number of turns per revolution = 55 / 5.6 = 9.8 turns

- Q:An AC adapter for a telephone answering machine uses a transformer to reduce the line voltage of 120 V to a voltage of 8.00 V. The RMS current delivered to the answering machine is 570 mA. If the primary (input) coil of the transformer has 600 turns, then how many turns are there on the secondary (output) coil?What is the power drawn from the electric outlet, if the transformer is assumed to be ideal?What is the power drawn by the transformer, if 13.5 percent of the input power is dissipated as heat in the coils and in the iron core of the transformer?

- Hello Samantha, in case of ideal transformer the power at the out put would be the same as that in the input. To get the power we need voltage and current. Voltage at the out put is 8 V and current is 570 mA. Hence power consumed by the machine is 4.560 W. So the power drawn in case of ideal transformer will be the same as 4.560 W If the efficiency of the transformer is 86.5% (100-13.5) then the input power will be 5.27 W (approx) To get the number of turns in the secondary let us use Ns/Np Vs/Vp Hence Ns 600*8/120 40 turns.

- Q:Transformer if the boost and buck current will change? According to the power of the same should be high voltage side of the current point is also the opposite? Boost and buck can be specified?

- Completely correct transformer output power = input power x efficiency, However, this refers to the rated voltage and rated current The actual output current of the transformer is determined by the load.

- Q:A I have a 230V/12V, 3A step-down transformer. What will happen at primary side of transformer if I attach a 12V/5A device at secondary side? Will primary side attributes (such as voltage or current) change?

- Primary side you will get 230V , nothing will happen to Transformer, you must be very care full do not touch the primary side just measure it with multimeter

- Q:I am completing an essay on how to improve the performance of a transformer. Please could someone advise me on the problems incurred in transformers and ways that have been designed to reduce these problems. Thanks in advance

- To improve the performance of a transformer, you have to:- [1] Reduce the copper losses, and [2] reduce the iron losses. Copper losses can be reduced by using copper wire of the highest purity; and by using copper wire that has the thinnest possible layer of insulating material on it. These measures, taken together, reduce the length of the wire and therefore its resistance. Iron losses are reduced by using magnetically soft iron in the laminations. This is the type of iron that has a tall and narrow hysteresis loop. Using copper wire with thin insulation (as mentioned above), keeps the windings close to the iron and so reduces magnetic leakage. A third measure is to use very thin laminations and to insulate them with very thin material as this will reduce eddy currents. It is very expensive to build a 99% efficient 250 MVA transformer. The losses in a 94% efficient version, are often cheaper to manage than the extra cost of making the 99% version.

- Q:I work in the power plant, today there is a task is to charge the lighting transformer, I would like to ask the next. What does it mean to charge the transformer? What does this charge mean? What is the use of? Thank you

- Is not wrong. Transformer itself is not stored function, that is, there is also a very short cut. You say is not to the transformer power ah

- Q:Here we go I have 4 transformers (230V to 12V) and 4 radio receivers. I have one transformer connected to one receiver. Similarly all transformers are connected in the same way. Now, I used a connection box (normal heavy duty ones bought at hardware shop-i think its made of some kinda fibre) to house 2 transformers and 2 receivers. This scenario is happening in my roof. I went to open one of the box the other and the transformer was hot. It wasn't hot to the point of not being able to hold it. But hot enough for me to hold it for for a while before letting go. So the basics here is that one transformer is only powering one receiver which is OK for the load. But I am a bit worried as to whether this can start a fire in the roof. Any advice please? Can this scenario lead to a fire? (Even though there is no overloading)

- It's possible but very unlikely. Many transformers have a heat-operated fuse connected in series so that it breaks before the transformer coils get dangerously hot. It will be hotter inside because the heat can't escape easily, so if the transformer fails the wire will melt inside it, not on the outside. If you are worried about it then you could either check if your transformers have such a fuse, or if they don't, you could fit one yourself. You could also fit the transformers into a big metal box with air vents and a fan to help keep things cool. It's normal for a transformer to get warm, just feel any mains adapter in use. The main component is a transformer. Electrical fires are caused mostly by bad connections sparking, or bad practice which allows a cable to get red-hot from an overload, something which will not happen in a standard installation, because fuses and breakers are installed to prevent it. There is a huge difference between the temperature your hand finds uncomfortable, and the temperature of melting copper which could cause a fire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SCB9-30-2500-10 Epoxy resin dry-type power transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords