SH15-M Amorphous Alloy Oil-immersed Transformer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

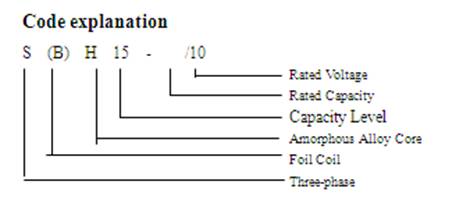

SH15-M Series

Amorphous Alloy Oil-immersed Transformer

Introduction of Products

Amorphous alloy isderived from iron, boron and other elements which rapid cooling down to mouldin order to arrange its atoms disordered. Compared with silicon sheets, the permeabilityof amorphous alloy is high, the no-load losses and current is lower, and moreoperation charges can be saved. Meanwhile, its heat is low,and it has good stability to make its working lifelonger.

Performance Characteristics

1. Saving power: The no-load losses reduce byabout 80% than that of S9 series.

2. Reliable: The capability of anti-shortcircuit is strong.

3. Protecting environment: Its noise is lowand it can decrease the discharging quantity of carbon.

Structure Characteristics

1. The core adopts three-phase five-limb and HV winding adopts D connection,which eliminates the three fluxes and three-harmonic electric potential anddecrease eddy current loss and temperature caused by leakage. Meanwhile, the steepnessof impulse voltage is reduced.

2. The coil takesthe shape of rectangular, and use conductor tensioning device to wind. Itadopts shaping, press mounting and other technique measures to make the outsidedimension of coil come to design requirement. And that HV coils wind outside LVcoils improve the strength of coil and the capability of anti-short circuit.

3. There is no oilstorage tank and moisture absorber on the oil tank. The transformer oil doesn’tcontact with the air and the expansion of oil depends on the elasticity of corrugatedplates to compensate. This can eliminate maintenance and improve working life.

Normal Using Condition

1. The altitude is not more than 1000m.

2. Environment temperature

Highest temperature: +40℃

Hottest monthly average temperature: +30℃

Highest yearly average temperature: +20℃

Lowest temperature: -40℃

3. Using outdoors( or indoors)

4. The wave shape of supply voltage is approximateto sine wave.

5. The supply voltage of three phases isgenerally symmetric.

If thetransformers need to be used at abnormal condition, the details should beoffered when the users order.

Main Specification and Technology Parameter

1. Range of rated capacity: 50~2500kVA

2. Rated voltage: not more than 10kv

3. Rated frequency: 50Hz

4. Insulating level

Voltage Grade (kv) | The highest voltage effective value of equipment(kv) | Rated short-time applied withstand voltage(kV/min) | Rated lightning impact withstand voltage(peak)(kv) |

≤1 | 1.1 | 3 | -- |

6 | 7.2 | 20 | 60 |

10 | 12 | 35 | 75 |

5. The insulating classof transformer is A, coil temperature rise is not more than 65K, and thetemperature rise of top oil is not more than 60K.

6. Thetransformers correspond with the following standards:

a. GB1094.1~2, GB1094.3, GB1094.5 Power transformer

b. JB/T 10318 Technology parameter and request of oil-immersedamorphous alloy core distribution transformer

c. Standard of InternationalElectro-technical Commission: IEC60076, Power transformer

d. Q/SIHG1 SH15-M Technology parameter andrequest of three-phase oil-immersed distribution transformer of amorphous alloycore sealed type

7. TechnologyParameter of SH15-M Series

Rated capacity (kVA) | Voltage and tapping range | Symbol of connecting group | No-load losses (W) | Load losses (W) | No-load current (%) | Impedance of short circuit (%) | ||

HV(KV) | Tapping range (%) | LV(kV) | ||||||

30 |

6 6.3 10 10.5 11 |

±5 ±2x2.5 |

0.4 |

Dyn11 | 33 | 630 | 1.7 |

4 |

50 | 43 | 910 | 1.3 | |||||

63 | 50 | 1090 | 1.2 | |||||

80 | 60 | 1310 | 1.1 | |||||

100 | 75 | 1580 | 1 | |||||

125 | 85 | 1890 | 0.9 | |||||

160 | 100 | 2310 | 0.7 | |||||

200 | 120 | 2730 | 0.7 | |||||

250 | 140 | 3200 | 0.7 | |||||

315 | 170 | 3830 | 0.5 | |||||

400 | 200 | 4520 | 0.5 | |||||

500 | 240 | 5410 | 0.5 | |||||

630 | 320 | 6200 | 0.3 |

4.5 | ||||

800 | 380 | 7500 | 0.3 | |||||

1000 | 450 | 10300 | 0.3 | |||||

1250 | 530 | 12000 | 0.2 | |||||

1600 | 630 | 14500 | 0.2 | |||||

2000 | 750 | 17400 | 0.2 |

5 | ||||

2500 | 900 | 20200 | 0.2 | |||||

Outline Dimension

Type | Outside dimension (mm) | Weight (kg) | |||

Length | Width | Height | Oil weight | Total weight | |

SH15-30 | 1100 | 690 | 1090 | 130 | 630 |

SH15-50 | 1190 | 750 | 1140 | 160 | 710 |

SH15-63 | 1250 | 750 | 1160 | 160 | 750 |

SH15-80 | 1290 | 750 | 1200 | 170 | 810 |

SH15-100 | 1260 | 800 | 1190 | 180 | 870 |

SH15-125 | 1320 | 810 | 1220 | 190 | 940 |

SH15-160 | 1370 | 810 | 1220 | 210 | 1050 |

SH15-200 | 1410 | 800 | 1320 | 230 | 1140 |

SH15-250 | 1490 | 810 | 1360 | 260 | 1290 |

S(B)H15-315 | 1520 | 790 | 1430 | 280 | 1500 |

S(B)H15-400 | 1670 | 820 | 1510 | 330 | 1710 |

S(B)H15-500 | 1650 | 910 | 1450 | 370 | 1960 |

SBH15-630 | 1830 | 920 | 1440 | 430 | 2250 |

SBH15-800 | 1910 | 950 | 1500 | 480 | 2730 |

SBH15-1000 | 2000 | 1100 | 1490 | 620 | 3330 |

SBH15-1250 | 2100 | 1100 | 1580 | 730 | 3560 |

S(B)H15-1600 | 2120 | 1240 | 1560 | 860 | 3830 |

A comparison about no-load losses of amorphous alloyand silicon sheet

Capacity (KVA) | No-load losses (w) | |

S9 type (silicon sheet) | SHI5 type (amorphous alloy) | |

100 | 290 | 75 |

315 | 670 | 170 |

500 | 960 | 240 |

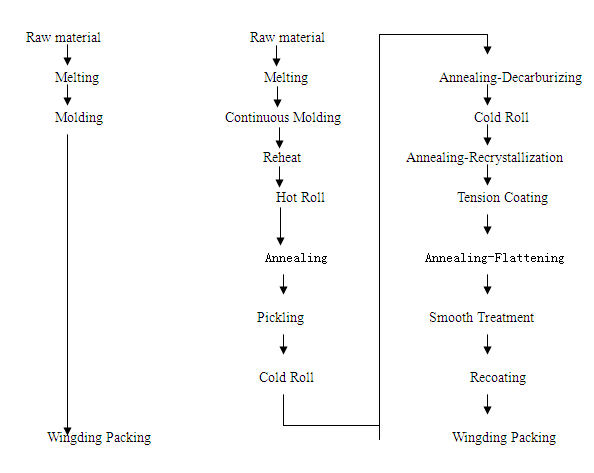

The Manufacturing Process of Amorphous Alloy Materials

a. The raw materials melt in the induction furnace.

b. The melted materials are transferred to feedingpart.

c. Control of casting head

d. After melting to be thin, it is sprayed to coolingwheel.

e. The sprayed materials cool down at the speed of 106℃ per second to form amorphous alloybelt.

f. Measure the width and thickness of alloy belt andfeedback to control system.

g. It is led to pull through unit.

h. Material receiving

A comparison to manufacturingprocess of amorphous alloy and silicon sheet

Amorphous alloy material Orientation silicon sheet

Social and Economic Effects

The manufacturingprocess of core materials of amorphous alloy core transformers is simple, andthe energy source losses are little, so the carbon discharge can be reduced.

No load losses are low, and the increased investment cost of transformers can be taken back within5 years.

Low operation temperature, small insulation deterioration, long working life.

The ordering basic data

1、Rated capacitance;

2、Rated voltage;

3、Rated frequency;

4、Tapping range;

5、Impedance voltage;

6、Using condition;

7、Other performance data should be indicated inthe contract.

- Q:Distribution transformer

- Not sure what you are asking. Transformers are wound for the best magnetic coupling possible to keep loses to a minimum.

- Q:I purchased a doorbell in Europe, it has a transformer that goes from 220V to 14.8V, will the transformer work on 110, or do I have to replace the transformer?

- If the mains side (primary) has a switch or 4 connections then it can probably be configured to work, as some transformers have dual 110v windings and are connected in series for 220v and parallel for 110v. Otherwise its not up to it.

- Q:Transformer short-circuit impedance is big good, or small good? The same capacity, voltage ... solution

- Transformer impedance depends on the size of many factors: 1 circuit breaker breaking capacity. Transformer below the power distribution board in a variety of electrical equipment has parameters, you should calculate the short-circuit current according to the impedance of the transformer to verify that these electrical equipment can meet the requirements, the same capacity and variable ratio of the transformer, the impedance of small short-circuit current, Large short-circuit current is small; 2 transformer connected to the large-capacity motor starting voltage. If the transformer load capacity close to the transformer capacity of 1/4 of the motor, should pay attention to check its starting voltage to meet the motor terminal voltage above 70% of the rated voltage. Impedance of the transformer itself is also a large pressure drop, more difficult to meet the requirements; small impedance transformer for the start of the pressure drop better performance; because you do not know how much the transformer capacity, it can not be the absolute conclusion, if the transformer capacity below 1000KVA , The above parameters in 4% and 6% or less, the choice of 4% better

- Q:A CD player uses two 1.5 v batteries. If you want to plug it into a 120 v outlet, what kind of transformer will you need (Step up or Step down)? What must be the ratio of the number of turns in the primary to the number of turns in the secondary?

- You will need more than just a transformer to do the job. What you need is a power supply that has other components like diodes. and capacitors, As the other answerer said, it is easiest to buy a Universal Adaptor , with an adjustable (by switch) output voltage and output polarity and they come with an assortment of connectors. If you really want to build a power supply then first consider that the peak value of the 120Vac-?мs source 120√2 ≈ 170 volts. You need 1.5 + 1.5 3 volts (if the batteries are in series) so you'll need a transformer of about 170 ? 3 56:1 (stepdown) Depending on the filtering used, and the losses, and the actual voltage level at your home outlet (I've seen ?мs values from 110 Vac to 125 Vac), a 45:1 transformer would be better. The transformer must be rated at 60 Hz.

- Q:If a transformer rating 240vac 50hz being supplied by a source 240vac 60hz,will it get hotter than by 240vac 50hz source?

- Hard to say. higher frequency lower magnetization current lower copper losses but higher magnetic losses. It depends on specific construction of the transformer. Roughly I'd say no significant change in heat dissipation.

- Q:I bought a Neon Sign Transformer over OKorder and for a while it worked great. I used it to power a Jacobs Ladder (I wired the transformer straight to the Jacobs ladder). However, now the transformer will turn on the jacobs ladder but after a couple of seconds it will shut off and sometimes make a buzzing noise. What is wrong with it and how can I fix it?

- You have 2 problems there. 1. Voltage; 2. Frequency. In this case, both are against you. NZ has 50Hz mains frequency at 240V. If you are really lucky, the transformer will have dual windings on the primary, or a 220/240V. tap. If you don't know what you are doing, consult an electrician or electronics tech. to have them check whether it is dual voltage, and change it. The frequency difference can mean a little less efficiency, the transformer may get a little warmer in operation. But it should be fine. You only other options are to replace the transformer (get one for dual voltages?), or use a 240/110V stepdown transformer ahead of it. The stepdown transformer must have a sufficient power rating for the job.

- Q:(1) A Step Up transformer steps up voltage.(2) Voltage is directly proportional to Power.Conclusion: A Step Up transformer has the capacity to increase Power.Contradiction: By First Law of Thermodynamics, Energy can neither be created nor be destroyed. Hence No one can create energy out of thin air like, that of by just using a Step Up transformer to increase voltage and hence power.Where is the whole theory wrong?

- voltage is inversely proportional to current, if the voltage increases then the current decreases . as long as the power remains the same. P I x V if you increase the voltage then the current should decrease proportionaly, that is how they can distribute high voltage over long distances using such small conductors . the current is very low

- Q:What is a transformer?

- First talk about the buck, usually we use a variety of voltage, such as life lighting is 220V, industrial safety lighting is 36V, welding machine voltage also need to be adjusted, which are inseparable from the transformer, the transformer through the main and auxiliary coil electromagnetic Mutual inductance principle, can reduce the voltage to the voltage we need. In the process of long-distance voltage transmission, we need to raise the voltage to a high, in order to reduce the voltage loss, usually rising to several thousand volts or even tens of kilovolts, which is the role of the transformer.

- Q:Do you think transformers is a good movie?Whos your favourite team autobots or decepticons?Whos your favourite transformer?And whats the best scene in the film?

- Transformers was a AWESOME MOVIE!, but it really annoys me when people tell me that the only thing good was the special affects. It takes really talented actors to play only on green screen, and the acting was very funny AND dramatic. My favorite are the Deceptions, just cause they have those really small things that can turn into stuff. I can't remember what they were though. My favorite transformer is Bubblebee, because it can talk through the radio which when I was kid was what I wished I could do. I my favorite scene probably is when the Autobots are causing mayhem while Sam is trying to find the glasses. I love it that Mojo peed on that one.

- Q:Step-up transformer, low-voltage winding put the middle, that is, low-high; Step-down transformer, medium voltage winding in the middle, that is, low high. For the step-up transformer, the input is low and the output is high or medium; the low-lying intermediate makes it possible to minimize the distance in the low-high, low-, thereby reducing the distance traveled by the magnetic energy, Loss, reduced low - high, low - in the leakage resistance, thereby reducing the low - high, low - between the short - circuit voltage percentage, thereby reducing the reactance, thereby improving the energy conversion efficiency of the transformer. For buck transformer, the input is high, the output is low or medium, similar to the step-up transformer, the optimal arrangement should be low, high, medium. However, due to insulation safety problems, the high voltage side must be placed at the outermost end. So the arrangement of sub-optimal way to low, medium and high.

- 2, from the manufacturing cost considerations, the transformer core is grounded. Low voltage coil inside, the coil on the core of the insulation distance can be smaller. So that the sum of the main insulation dimensions of the three coils will be smaller. The weight of the entire transformer, the volume is relatively lower than the - low - high arrangement to be smaller.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SH15-M Amorphous Alloy Oil-immersed Transformer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords