PU Conveyor Belt White Food Grade Industrial Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PU Conveyor Belt White Food Grade Industrial Belt

Conveyor Belt Description:

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

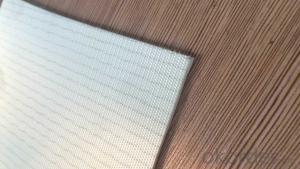

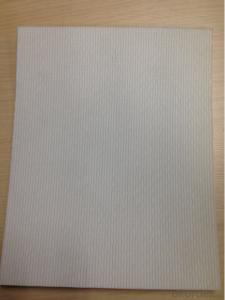

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Application:

PVC Belting: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines.

PU Belting: Most applicable to the food industry and other industries .

Conveyor Belt Feature

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Special wear resistant edge design;

Conveyor Belt Specifications

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Conveyor Belt Application

Food conveyor belt

Plate conveyor belt

Printing machine of conduction band

Oil resistant conveyor belt

Knife edge conveyor belt

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can olive nets be used in olive groves with uneven terrain?

- Yes, olive nets can be used in olive groves with uneven terrain. The nets can be adjusted and installed to accommodate the varying elevations and slopes of the grove, ensuring effective coverage and protection for the olives.

- Q:How do olive nets prevent olives from getting damaged during transportation?

- Olive nets prevent olives from getting damaged during transportation by providing a protective barrier that minimizes contact between the olives and any hard surfaces or objects. The nets act as a cushioning layer, absorbing shocks and vibrations during transportation, thus reducing the risk of bruising or other damage to the olives. Additionally, the nets help to maintain the integrity of the olive clusters, preventing them from becoming loose or dislodged during transit.

- Q:Can olive nets be used in windy conditions?

- Yes, olive nets can be used in windy conditions. However, it is important to ensure that the nets are properly secured and anchored to prevent them from being blown away by strong winds. Additionally, using heavier or more durable nets specifically designed for windy conditions may be advisable.

- Q:Can olive nets be used on olive trees grown in containers?

- Yes, olive nets can be used on olive trees grown in containers. Olive nets are commonly used to protect olives from birds and other pests. Whether the olive tree is grown in a container or in the ground, the nets can be draped over the tree to provide protection.

- Q:Are there any specific guidelines for using olive nets on olive trees with specific soil requirements?

- Yes, there are specific guidelines for using olive nets on olive trees with specific soil requirements. The soil should be well-drained and have a pH level between 6 and 8, as olive trees thrive in these conditions. Additionally, it is important to avoid excessive watering, as it can lead to root rot. Proper soil preparation, including adding organic matter and ensuring proper drainage, is crucial for successful olive tree cultivation with the use of olive nets.

- Q:Can olive nets be used on trees with a small trunk?

- Yes, olive nets can be used on trees with a small trunk.

- Q:What are the dimensions of a standard olive net?

- The dimensions of a standard olive net can vary, but commonly they are around 10-15 feet in width and 30-50 feet in length.

- Q:How to make up the holes in the plastic basin, and the method is simple and durable

- Looking for a plastic basin with similar colors of waste plastic, with electric irons gently hot, slowly copper leakage to close, you can.

- Q:Do olive nets affect the yield of olives?

- Yes, olive nets can affect the yield of olives. These nets are commonly used in olive farming to prevent birds and other animals from consuming the fruits. By protecting the olives from being eaten, olive nets can help increase the overall yield of olives by ensuring that a larger proportion of the fruits reach maturity and are available for harvesting.

- Q:Are there any disadvantages to using an olive net?

- Yes, there are a few disadvantages to using an olive net. Firstly, the net can sometimes damage the branches and leaves of the olive trees if not properly installed or removed. Additionally, if the net is not securely fastened, birds and other pests may still be able to access the olives. Furthermore, using a net can be time-consuming and labor-intensive, as it requires manual installation and removal. Finally, if the net is not properly maintained, it may accumulate debris and become a breeding ground for pests or diseases.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PU Conveyor Belt White Food Grade Industrial Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords