Whie PU Conveyor Belt For Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

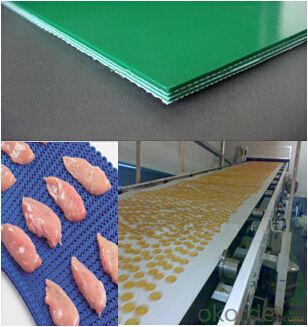

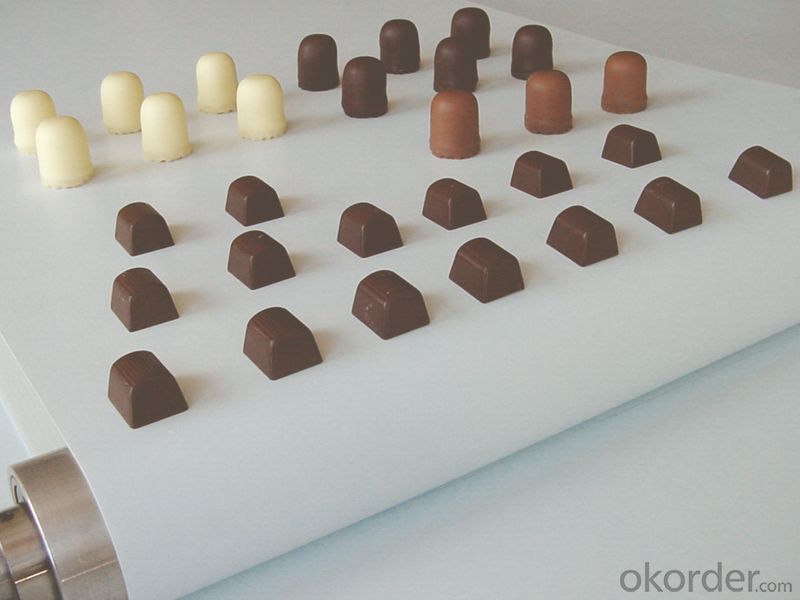

Whie Food PU Conveyor Belt For Food Processing Industry

PU Conveyor Belt

Material: PU,Shape: plain (flat surface),Thickness: 1mm

Specifications: one ply fabric-one ply PU

Tensile strength: >150N/mm

Temperature range: -10°C~+90°C

Color: white

Applications: conveyance and production assembly lines in the areas of cigarettes, foodstuffs, electronics, pharmaceuticals, drinks and papermaking Specification.

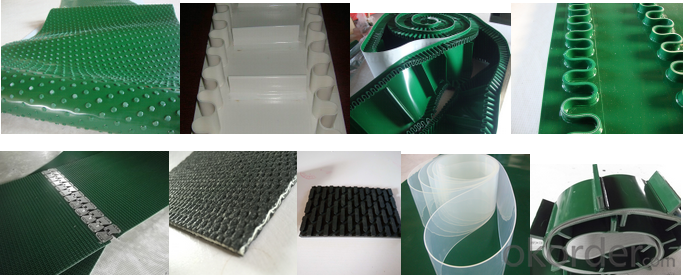

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product Pictures:

Our Company:

Pls contact me freely if any inquiry,thank you!

- Q:What are the distinguishing features of plastics? What is their chemical name?

- Generally refers to large output, wide use, good formability, cheap plastic. There are five kinds of general plastics, namely polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and acrylonitrile butadiene styrene copolymer (ABS). These five kinds of plastics accounted for the vast majority of plastic raw materials used, the basic can be classified as special plastic varieties, such as: PPS, PPO, PA, PC, POM and so on, they are in daily life in the small amount of the product, mainly used in the field of engineering, National defense science and technology industry and other high-end, such as automotive, aerospace, architecture, communications and other fields. Plastics are classified into thermoplastic and thermosetting plastics according to their plasticity. Usually, thermoplastic plastic products can be recycled, and thermosetting plastics are not, according to the optical properties of plastics to points, can be divided into transparent, translucent and opaque materials, such as PS, PMMA, AS and PC belong to the transparent plastic, and most other plastics are made of opaque plastic.

- Q:Are there any regulations or guidelines for using olive nets?

- Yes, there are regulations and guidelines for using olive nets. These guidelines may vary depending on the specific region or country. However, common regulations typically include ensuring the nets are properly installed and secured to prevent damage to the olive trees, using nets with appropriate mesh sizes to avoid entanglement of birds or other animals, and adhering to specific harvesting and storage practices to maintain the quality of the olives. It is advisable to consult local agricultural authorities or olive farming associations for specific regulations and guidelines in your area.

- Q:Are olive nets flame retardant?

- No, olive nets are not typically flame retardant.

- Q:Can olive nets be used for both small and large-scale olive oil production?

- Yes, olive nets can be used for both small and large-scale olive oil production. Olive nets are commonly used during the olive harvesting process to catch the falling olives, preventing them from hitting the ground and potentially getting damaged. This method is suitable for both small-scale farmers who manually collect the olives as well as large-scale operations that employ mechanical harvesting techniques. Olive nets are versatile and can be employed in various olive orchard sizes to ensure efficient olive oil production.

- Q:Does high strength polyurethane belong to plastics?

- But now there are some materials that are both plastic and rubber, and it's difficult to identify which category, such as TPO, TPV, elastomer nylon (material for car tires)

- Q:Standard for classification of fire protection in plastic products

- Plastic flame retardant grade by HB, V-2, V-1 gradually increase to V-0: 1, HB:UL94 standards in the bottom of the flame retardant grades. For a sample of 3 to 13 mm thick, combustion rate is less than 40 mm per minute;

- Q:Do olive nets require any special storage conditions?

- Yes, olive nets require special storage conditions to maintain their effectiveness and longevity. They should be stored in a cool, dry place away from direct sunlight to prevent damage from UV rays. Additionally, it is crucial to keep them away from any sharp objects or chemicals that could potentially cause tears or deterioration. Proper storage will help preserve the quality and lifespan of olive nets.

- Q:What is the white fine plastic rope hanging with a tag on it?

- The white, thin plastic rope hanging from the coat is called a nylon rope.

- Q:Are there any disadvantages of using olive nets?

- Yes, there are a few disadvantages of using olive nets. Firstly, olive nets can be quite expensive to purchase and maintain. They require regular cleaning and maintenance to ensure they remain effective. Additionally, olive nets can be time-consuming to set up and take down, especially in larger orchards. They can also obstruct sunlight, potentially affecting the growth and health of the olive trees. Finally, if not properly secured, olive nets can pose a hazard to wildlife and may inadvertently trap or harm birds and other animals.

- Q:Can olive nets be used for olive trees in regions with limited labor availability?

- Yes, olive nets can be used for olive trees in regions with limited labor availability. Olive nets are commonly used for harvesting olives, especially in areas where labor is scarce or expensive. These nets are spread under the trees, and when the olives are ripe, they can be shaken or combed from the branches onto the nets. This method minimizes the need for manual picking, making it more feasible and cost-effective in regions with limited labor resources.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Whie PU Conveyor Belt For Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords