Plastic Geocell for Slope Protection with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Geocell for Slope Protection:

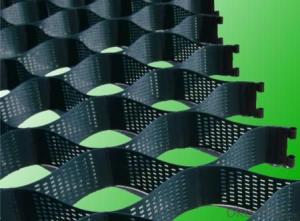

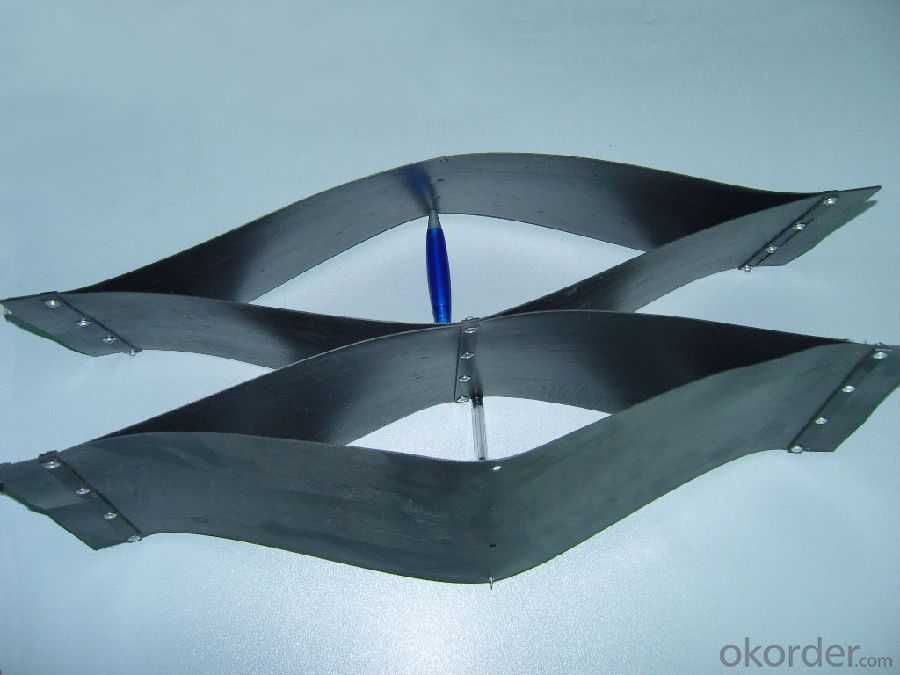

The product has the features of high-strength, durable, light weight. In process of construction, the geocell can be pulled into a honeycombed grid and then filled with various materials to provide a solution for erosion control, load support and earth retention projects. Therefore, it is widely used in stabling soft roadbed and bearing the load of dike.

Main Features of Plastic Geocell for Slope Protection:

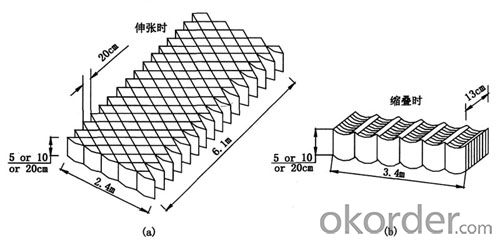

1. flexible to fold during transportation, stretching out

2. filled with stone or concrete during service, forming into structure with powerful lateral confinement and rigidity.

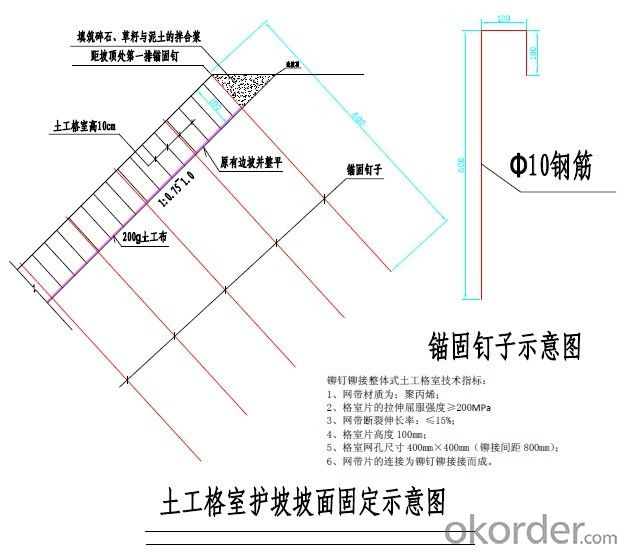

3. used as cushion coat to strengthen loading capacity of weak ground or slope protection structure

Specifications of Plastic Geocell/HDPE geocell:

1. Fix railway ground.

2.Fix weak ground of roads and increase loading capacicity.

4.used to build the support block struction

5.Act as independent wall, dock and break-water.

6.Treat desert, beach, riverbed and bank.

Geocell Product Poperties

| Height (mm) | Welding distance (mm) | Sheet thickness(mm) | Tensile yield strength of the cell≥(MPa) | Seam peel strength≥(N) | ||

| smooth | textured | |||||

| TGLG-50-400 | 50 | 400 | 1-1.1 | 1.4-1.5 | 20 | 500 |

| TGLG-100-400 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

| TGLG-150-400 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

| TGLG-200-400 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

| TGLG-75-330 | 75 | 400 | 1-1.1 | 1.4-1.5 | 20 | 750 |

| TGLG-100-330 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

| TGLG-150-330 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

| TGLG-200-330 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

Applications of Plastic Geocell/HDPE geocell:

*Erosion Control

*Load Support

*Slope Protection

*Channel Protection

*Retaining Wall

*Ground Stabilisation

now most of our products are exported to Chile,Mexico,Brazil, Argentina , Russia, Poland, Turkey, USA, UK, Iran,and etc.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What are the materials of the geomembrane?

- Mainly include polyvinyl chloride (PVC) and polyethylene (PE), corrosion-resistant, EVA (ethylene & # 47 geomembrane taking plastic film as anti-seepage base material, good extensibility. Currently, they are a kind of polymer chemistry flexible material, the material used for seepage-proofing at home and abroad is plastic film, high?adaptability?to the?deformation; vinyl acetate copolymer), smaller proportion, and design use ECB (ethylene vinyl acetate modified bitumen blend geomembrane) in tunnel application, low temperature resistance, good anti-frost?property. , geotechnique impermeable material combined with non-woven fabric. Its anti-seepage property mainly depends on the anti-seepage property of plastic film.

- Q:Are geomembranes suitable for use in fish farming tanks?

- Yes, geomembranes are suitable for use in fish farming tanks. Geomembranes are impermeable membranes that provide a barrier to prevent the seepage of water, chemicals, and other substances. They are commonly used in fish farming tanks to create a watertight environment, maintain water quality, and prevent contamination. Geomembranes are durable, flexible, and resistant to UV radiation, making them an ideal choice for fish farming tanks.

- Q:Are geomembranes suitable for wastewater treatment?

- Yes, geomembranes are suitable for wastewater treatment. They are impermeable liners made of synthetic materials that can effectively contain and prevent the leakage of contaminants from wastewater treatment facilities. Geomembranes can be used in various applications such as lining ponds, lagoons, and tanks, providing a reliable barrier to protect the environment from potential pollution. They are durable, long-lasting, and resistant to chemical degradation, making them an ideal choice for wastewater treatment systems.

- Q:What is geotextile

- The geotextile is also known as the geotextile, which is made of synthetic fibers that are made of permeable synthetic material by needle punching or weaving. Finished product is cloth form, the general width is 4-6 meters and the length is 50-100 meters. The geotextile is divided into woven geotextile and non-woven geofabric. The geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention and protection, and has the characteristics of light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance and corrosion resistance.

- Q:Design materials of geomembrane

- embedding. Highway anti-seepage treatment, take minimum seams of construction as principle: the central median when the lower part Impervious generally use a cloth membrane 200-300g / m. Based on the water pressure requirements of engineering design. When the base layer is concrete structure, the construction conditions, to determine the width and length of geomembrane:. // F, to determine the thickness of the geomembrane, climate conditions:. // F, construction capacity. According to the actual size, life and other application conditions of the project, and according to the project nature exposure, the application site.

- Q:What's the repair method of membrane keyboard?

- Membrane repair is a little difficult. First you need to find out where goes wrong. Cut off part of the thin iron wire which is a little longer than that of the damaged circuit, cut off a section of scotch tape, put the iron wire clipped with tweezers on the scotch tape, align the tweezers with the circuit, adhere the circuit to the tape and press, and the problem is solved.

- Q:How to remove the casings lamination of laptop?

- If you don't want the protective film, you can pry one of its corner, blow it slowly until it is hot with a hair dryer, and wipe the screen with computer cleaning agent. It is usually workable in this way. But if you are inattentive, it is easy to leave residue on the computer screen and its appearance will be affected.

- Q:Why the lacquer film is not hard enough?

- Generally speaking, there are three reasons. First it is brushed too thick. Second the time is not enough. Third, the temperature is too low.

- Q:What are the geogrids?

- Geogrids are 2D latticed grids or three-dimensional screen grids made from high-molecular polymers like polypropylene and PVC (polyvinyl chloride) by thermoforming or mould pressing. They are used in the field of civil engineering.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Geocell for Slope Protection with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords