All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is the impact of weather conditions managed to prevent delays and complications in earthwork projects?

The impact of weather conditions on earthwork projects is managed through various strategies and precautions to prevent delays and complications. Firstly, comprehensive planning and scheduling are essential to account for potential weather-related disruptions. This includes identifying weather patterns and historical data to anticipate adverse conditions and adjust project timelines accordingly.

Secondly, constant monitoring of weather forecasts and real-time updates is crucial to stay informed about any upcoming storms, extreme temperatures, or other adverse weather events. This enables project managers to take proactive measures such as rescheduling work, reallocating resources, or implementing additional safety measures to minimize delays and complications.

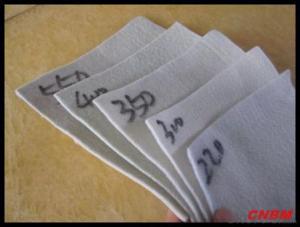

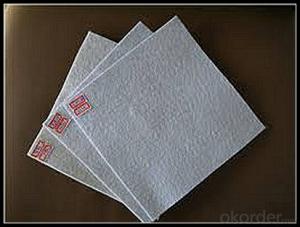

Furthermore, implementing appropriate construction techniques and using weather-resistant materials can help mitigate the impact of adverse weather conditions. For example, using erosion control measures like retaining walls and geotextiles can prevent soil erosion during heavy rainfall.

Collaboration and communication among project stakeholders are also vital in managing weather-related challenges. Regular coordination with construction teams, subcontractors, and suppliers allows for quick adjustments in the event of unexpected weather disruptions. Additionally, maintaining open lines of communication with clients, regulatory authorities, and insurance providers ensures that everyone is informed and prepared for potential delays or complications.

In summary, managing the impact of weather conditions in earthwork projects requires careful planning, monitoring, adaptability, and effective communication. By implementing these strategies, delays and complications can be minimized, allowing projects to progress smoothly and efficiently.

What role does material selection play in earthwork projects near retaining walls?

Material selection plays a crucial role in earthwork projects near retaining walls as it directly impacts the stability, durability, and overall performance of the wall. The selected material should possess adequate strength, proper drainage characteristics, and compatibility with the surrounding soil to ensure the wall's integrity and prevent any potential failures or deformations. Additionally, considering factors like the wall's height, soil properties, and environmental conditions is essential to choose the appropriate material that will effectively resist lateral earth pressure and provide long-term stability.

What are the various methods for measuring and controlling settlement in earthwork?

There are several methods for measuring and controlling settlement in earthwork. Some common methods include using settlement plates, settlement gauges, and settlement surveys.

Settlement plates are typically installed at specific locations within the earthwork area. These plates are made of concrete or steel and are designed to settle along with the surrounding soil. By periodically measuring the settlement of these plates using a leveling instrument, engineers can determine the amount and rate of settlement.

Settlement gauges are another method used to measure settlement in earthwork. These gauges are typically installed vertically and consist of a series of rods with markings. As the soil settles, the rods will move, and engineers can measure the settlement by comparing the current position of the rods with their initial position.

Settlement surveys involve the use of surveying techniques to measure settlement. This method typically includes establishing a network of survey points around the earthwork area and periodically measuring the change in elevation at these points. By comparing these measurements over time, engineers can determine the settlement.

Controlling settlement in earthwork can be achieved through various techniques. One common method is preloading, where additional weight is applied to the soil before construction to accelerate settlement. This helps to minimize future settlement during the construction process.

Other techniques for controlling settlement include soil stabilization, such as using geotextiles or chemical additives to improve the soil's strength and reduce settlement. Additionally, proper compaction and moisture control during construction can help to minimize settlement.

Overall, the various methods for measuring and controlling settlement in earthwork are essential for ensuring the stability and long-term performance of structures built on or in the ground.

Wholesale Earthwork from supplier in Sweden

Our team of experts is highly experienced and well-trained in all aspects of Earthwork solutions. We offer a wide range of products, including excavation equipment, construction materials, and soil stabilization products. Whether you need equipment for large-scale excavation projects or materials for landscaping and gardening, we have everything you need.

In addition to our extensive product portfolio, we also offer a range of services to ensure that your Earthwork projects run smoothly. Our dedicated sales team will work closely with you to understand your specific requirements and provide customized solutions. We offer competitive pricing and flexible payment options to suit your budget.

Furthermore, our technical assistance team is always available to provide support and guidance throughout your project. They can help with everything from equipment selection and operation to troubleshooting and maintenance. We are committed to delivering high-quality products and services that meet the highest industry standards.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry developments and offer innovative solutions to our clients. We are constantly investing in research and development to ensure that we can provide the most advanced and efficient Earthwork solutions in Sweden.

Whether you are a contractor, developer, or homeowner, we have the knowledge, experience, and products to meet your Earthwork needs. Contact us today to discuss your project requirements and discover how we can assist you in achieving your goals.

In addition to our extensive product portfolio, we also offer a range of services to ensure that your Earthwork projects run smoothly. Our dedicated sales team will work closely with you to understand your specific requirements and provide customized solutions. We offer competitive pricing and flexible payment options to suit your budget.

Furthermore, our technical assistance team is always available to provide support and guidance throughout your project. They can help with everything from equipment selection and operation to troubleshooting and maintenance. We are committed to delivering high-quality products and services that meet the highest industry standards.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry developments and offer innovative solutions to our clients. We are constantly investing in research and development to ensure that we can provide the most advanced and efficient Earthwork solutions in Sweden.

Whether you are a contractor, developer, or homeowner, we have the knowledge, experience, and products to meet your Earthwork needs. Contact us today to discuss your project requirements and discover how we can assist you in achieving your goals.