All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

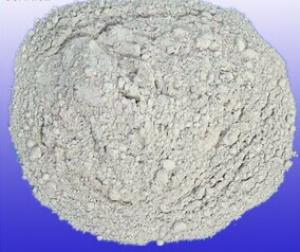

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in molding applications?

Monolithic refractories perform exceptionally well in molding applications due to their high resistance to thermal shock, excellent thermal conductivity, and ability to withstand extreme temperatures. They provide superior insulation, ensuring consistent heat distribution throughout the mold, and their high mechanical strength allows for the creation of complex shapes and intricate molds. Additionally, monolithic refractories have low porosity, reducing the risk of defects and improving the overall quality of the molded products.

How do monolithic refractories contribute to reducing the need for frequent repairs in industrial equipment?

Monolithic refractories contribute to reducing the need for frequent repairs in industrial equipment by providing high thermal resistance and superior strength. These refractories are designed to withstand extreme temperatures and harsh operating conditions, preventing them from deteriorating quickly. Their monolithic nature allows for easy installation and repair, minimizing downtime and the need for frequent maintenance. Overall, monolithic refractories enhance the durability and longevity of industrial equipment, reducing the frequency of repairs needed.

How do monolithic refractories improve the energy efficiency of a furnace or kiln?

Monolithic refractories improve the energy efficiency of a furnace or kiln by providing superior insulation properties, reducing heat loss and improving heat transfer within the system. This allows for better temperature control, lower fuel consumption, and increased overall energy efficiency.

How do monolithic refractories compare to precast shapes in terms of performance?

Monolithic refractories and precast shapes have different advantages and disadvantages in terms of performance. Monolithic refractories are versatile and can be easily installed in various shapes and sizes, offering flexibility in design. They have good thermal shock resistance and can withstand high temperatures. On the other hand, precast shapes are specifically designed for a particular application, ensuring precise dimensions and optimal performance in specific areas. They have excellent dimensional accuracy and can often be installed faster. Ultimately, the choice between monolithic refractories and precast shapes depends on the specific requirements of the application.

How do monolithic refractories handle thermal cycling?

Monolithic refractories are designed to handle thermal cycling by possessing excellent thermal shock resistance, which allows them to withstand rapid and frequent temperature changes without cracking or spalling. Their composition and bonding materials enable them to expand and contract uniformly during heating and cooling cycles, ensuring their stability and durability even under extreme thermal conditions.

Wholesale Monolithic Refractories from supplier in Sweden

Our commitment to quality and innovation sets us apart from our competitors. We continuously invest in research and development to ensure that our Monolithic Refractories are of the highest standards and meet the evolving needs of the industry.

In addition to our product offerings, we also provide a range of services to support you throughout the entire project lifecycle. Our technical experts can assist with installation, maintenance, and troubleshooting, ensuring that your Monolithic Refractories perform optimally and have a longer lifespan.

Furthermore, we understand the importance of sustainability and environmental responsibility. Our Monolithic Refractories are designed to minimize energy consumption and reduce emissions, helping you meet your sustainability goals.

By choosing us as your Monolithic Refractories supplier in Sweden, you can rest assured that you are partnering with a reliable and trusted company. We have a proven track record of delivering high-quality products and services to numerous satisfied customers in various industries.

Contact us today to learn more about our Monolithic Refractories and how we can support your projects in Sweden. Let us be your preferred partner for all your refractory needs.

In addition to our product offerings, we also provide a range of services to support you throughout the entire project lifecycle. Our technical experts can assist with installation, maintenance, and troubleshooting, ensuring that your Monolithic Refractories perform optimally and have a longer lifespan.

Furthermore, we understand the importance of sustainability and environmental responsibility. Our Monolithic Refractories are designed to minimize energy consumption and reduce emissions, helping you meet your sustainability goals.

By choosing us as your Monolithic Refractories supplier in Sweden, you can rest assured that you are partnering with a reliable and trusted company. We have a proven track record of delivering high-quality products and services to numerous satisfied customers in various industries.

Contact us today to learn more about our Monolithic Refractories and how we can support your projects in Sweden. Let us be your preferred partner for all your refractory needs.

Hot Search

- Monolithic Refractories in South Korea

- Ceramic Fiber Products in Rwanda

- Refractory Bricks in Mongolia

- Raw Materials For Refractory in Germany

- Ceramic Fiber Products in Lithuania

- Monolithic Refractories in Guyana

- Monolithic Refractories in Nicaragua

- Raw Materials For Refractory in Laos

- Refractory Bricks in Ireland

- Ceramic Fiber Products in Moldova