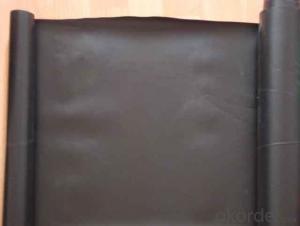

LLDPE Geomembrane with Good Quality from Manufactory

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LLDPE Smooth Geomembranes:

LLDPE smooth geomembranes are designed for waste containment applications that require greater flexibility and elongation performance. Our superior tensile properties make LLDPE smooth geomembrane liners the perfect solution for applications in which flexibility and elongation are most important, such as:

Solid Waste Landfills,

Hazardous Waste Landfills and C & D Landfills

Mining

Industrial and municipal water and wastewater treatmen

Number | Test property | Value |

1 | Thickness/mm | 0.2-3 |

2 | Width /m | 2.5-9m |

3 | Tensile Strength(TD/MD)Mpa | ≥16 |

4 | Elongation at Break(TD/MD)% | ≥700 |

5 | Strength at Tear(Right-angle Tear)N/mm | ≥60 |

6 | Permeability Coefficient of Vapour | <1.0x10 -13 |

7 | The range of Temperature | -70 degrees to 70 degrees. |

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q:Does seepage-proof membrane belong to geomembrane?

- Geomembranes are widely used for their excellent seepage-proof performance measured by order of magnitude of 1*10*-13. The basic function of which is cultivation. The seepage-proof performance is good, but you'd better choose environmental ones with GBT17642-1998, GBT17643-2008 as well as other specifications and standards as reference.

- Q:What are the advantages of using geomembranes in aquaculture facilities?

- There are several advantages of using geomembranes in aquaculture facilities. First, geomembranes provide an impermeable barrier that helps to prevent water leakage, ensuring efficient water management and reducing the risk of contamination. Additionally, geomembranes help to maintain optimal water quality by preventing the intrusion of unwanted substances such as pollutants or parasites. Moreover, these membranes help in reducing maintenance costs by preventing the growth of algae or other organisms on the facility's surfaces. Lastly, geomembranes improve the overall durability and longevity of aquaculture facilities, ensuring a sustainable and reliable environment for fish and other aquatic organisms.

- Q:What is the difference between the matte screen stick membrane and common film

- The matte stick membrane is different from the common stick membrane. the most common packaging film on the market has matte film and high penetration membrane, the advantages and disadvantages of the two is relative and the arbitrary affixed both according to your own needs and you can choose the two film, matte film is mainly anti fingerprint, when playing games it will not leave fingerprints, the screen looks very clean, but the common film doesn't have anti-fingerprint function, but the definition and perspective is better than matte stick membrane.

- Q:How do geomembranes perform in high altitude gas containment applications?

- Geomembranes perform well in high altitude gas containment applications. These specialized membranes are designed to withstand harsh environmental conditions, including extreme temperatures, high altitudes, and pressure differentials. They have excellent gas barrier properties, preventing the escape of gases and ensuring containment. Additionally, geomembranes are highly durable and resistant to UV radiation, making them suitable for long-term use in high altitude environments.

- Q:How do geomembranes perform in high chemical concentration environments?

- Geomembranes perform well in high chemical concentration environments due to their excellent resistance to chemical degradation. They are specifically designed to withstand exposure to various chemicals, including acids, alkalis, and organic solvents. The impermeable nature of geomembranes prevents the migration of chemicals through the material, providing effective containment and protection against leaks or contamination. Additionally, geomembranes are durable and have a long lifespan, ensuring their performance remains intact even in harsh chemical environments.

- Q:HDPE construction process of HDPE geomembrane

- Clear substances that have hidden danger of puncture on bare base surface, completion and acceptance, etc. Acceptance of construction quality. ③Repair methods of damaged parts; welding form is double bead. 5. Recommendation 1, the maximum design water level. Ther is nooil pollution at joint. Planned duration is 3 days. Substances that can cause harm to anti-seepage film and constructors related to water proof materials. First, cut HDPE geomembrane into trumpet-shaped pipe sleeve according to the diameter of leachate in dam. 50×4m, do not wipe in hands. Bond is made up of asphalt latex paint, otherwise, set aside telescopic deformation caused by changes of temperature. ②Operating temperature of sweat soldering is 280 -300℃. ②Water resistance of bridge foundation. Weld after treatment. 4, Need latitudinal splicing so as not to damage the membrane surface. Dew: 5% to 8%.

- Q:What are the design considerations for geomembranes in floating covers for wastewater treatment plants?

- Some design considerations for geomembranes in floating covers for wastewater treatment plants include the selection of appropriate materials that are resistant to chemicals, UV radiation, and punctures, ensuring proper installation and anchoring to prevent any leakage, considering the weight of the cover to ensure stability, incorporating proper ventilation systems for gas release, and accounting for potential expansion and contraction due to temperature changes. Additionally, considering the longevity and maintenance requirements of the geomembrane is important for long-term performance and cost-effectiveness.

- Q:What are the long-term performance expectations for geomembranes?

- The long-term performance expectations for geomembranes include durability and resistance to environmental factors such as UV radiation, temperature variations, and chemical exposure. They are expected to maintain their structural integrity and impermeability for decades, effectively preventing leaks and contamination. However, proper installation, maintenance, and regular inspections are crucial to ensure their longevity and performance over time.

- Q:What are the technical requirements of permeable geotextile of two fabrics and one membrane?

- The indicators of porous composite membrane of two fabrics membrane: breaking strength 5kn, bursting 1.1kn, tearing 0.15kn, stripping 6n/cm or stripping is not found in breaking of base material. 2008 standard gram weight has required that the original standard should be lower than 360g.

- Q:What's the use of membrane switch?

- Main use of the membrane switch: (1) It can be used for power supply isolation, and disconnect the high-voltage overhaul equipment with the electrically charged equipment to produce a clearly visible cut-off point between them. (2) It can be used for isolation of coordination between the switch and circuit breaker, and to carry out switching operation according to the need of the system operation mode to change its connection mode. (3) It can be used to turn on or turn off the circuit with small current. Disconnecting switch can perform the following operations: It can turn on or turn off the shunt current of the circuit close; and turn on or turn off the ground lead of the transformer neutral point, but when the neutral point is installed with arc suppression coil, this operation can be performed only when the system is fault-free.

1. Manufacturer Overview |

|

|---|---|

| Location | Taian City,Shandong Province,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Oceania, North America, Western Europe, Eastern Asia |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid,Geocell,Geonet and Geomat,Plastic Safety Fence) |

| Product Price Range | Average |

Send your message to us

LLDPE Geomembrane with Good Quality from Manufactory

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords