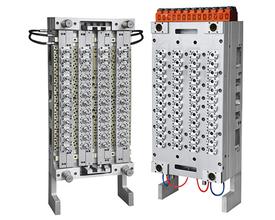

PET Preform Plastic Molds Injection PET Moulding Top Level

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET Preform Plastic Molds Injection PET Moulding Top Level

he thickness and weight of moulds are in accordance with the tubes,these measurments will change in case the products ar e improved.

Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms.

PET Preform Mould Main Components Specification and Advantages | ||

Main component | Specification and Advantages. | |

Core | 2316 steel from Sweden. | high quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

Neck | S136 steel from Sweden, HRC >60, International standard screw neck. | |

Cavity | 2316 steel from Sweden Each cavity have an independent temperature controller. Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm. | |

Body | P20 Steel material from Germany | |

Hot runner plate |

2344 Steel material from Germany

| |

Slider Plate | wear-resistant copper | |

specially designed cooling circuits | Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute | |

Hot runner design | make sure the high quality of preform products. | |

Heater | Anole Germany | |

valve gated design with Automatic drop | each cavity has its independent heating zone and temperature is measured by independent thermocouple.(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. | |

Precessed by high presion CNC machine and numerical control loathe machine | Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well.

| |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q:What is the difference between the p20 mould steel and the nak80-b mould steel

- P20 mould steel is American, its main application range is: the requirement of high hardness, high quality, good wear-resistant plastic mold, Nak80-b mould steel is a Japanese cargo, and its main application is: require hardness, erosion, and polishing. Also: nak80-b is harder than P20; Of course the price is more than the P20.

- Q:What is die parting face?

- This should be plastic (especially injection mould term. Generally speaking, the mould has two major components: dynamic model and fixed die (or male mold cavities and cores). Parting surface is closed and state can contact between the two parts.

- Q:What is the top and bottom die in the mould?

- Hello, before you answer your question, I want to tell you that you are just as misguided as any other student. Moulds itself no, under the touch, it's like: two tiles together, we can't say targeted on brick, brick, if there is a mould of lower die on concept, studied physics knows, it is need a reference or a reference point. Two cavity, the most common type of mold is the so-called two mould, is there are two main cavity, you can control open mould, also can open mould, therefore, only under the condition of upper and lower mould work, just have upper die, the meaning of the lower die.

- Q:What is replicas in the mold

- Does it mean the supermodel? It's the same mold that has two layers of molds, usually a disposable fork, spoon, crisper, and so on

- Q:How does the die rod work? Is it through the press?

- The principle of the work is: in the die and die, the rigid push device doesn't produce the push force, it is in the non-working condition; In open mold close to the biggest trip, installed in the press the slider widget dozen material beam rigidity force transfer to install in the upper die of the push rod, plate, connecting rod and push block, which launched within the die parts or waste.

- Q:Where is the mould industry in our country?

- Mould industry is mainly concentrated in ningbo and taizhou, zhejiang province, ningbo, ninghai, yuyao, cixi and yinzhou mainly produces plastic mold, beilun is given priority to with die casting, xiangshan and zhoushan is given priority to with casting and stamping die. Taizhou main mould manufacturing enterprise focuses on huangyan and road bridge, plastic mold is the majority. Zhejiang mould industry has some obvious characteristics. One is that the mold manufacturing enterprises are almost all private enterprises; Secondly, the mould enterprises have been relatively concentrated and have formed the mould market. Three is that the mould can meet different needs at different levels, and the high level of molds develops rapidly and has a large proportion. Fourth, we have created a number of high-caliber key enterprises through entrepreneurship. Fifth, the division of specialization has been formed by nature, and the main enterprises have obvious features. Sixth, the development of the mould industry is obvious to the local and regional industries.

- Q:Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- If solve the above problem is mould itself reason, please use red lead to mold fitting well, the original poster check mold in touch wear, wear a location, see if cooperate in place.

- Q:Why is the mold selected for quenching?

- Mold quenching process is in order to improve the wear resistance of molding parts are generally must carry on the quenching process, and achieve H RC52-57 0 in the parts of structure USES, core plate and ejector plate and plate type of components at the top of the molding or out of the plastic parts. When the bear larger unit extrusion pressure, also want to quenching process. Mold (mu ju), industrial production to injection molding, blow molding, extrusion, die casting or forging molding, smelting, the methods of stamping products of various molds and tools required. In short, the mold is a tool for molding objects, which are made up of various parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. There is the title of "mother of industry".

- Q:The role of the die positioning ring

- Then to mould a positioning, on the outside of the mold gate set with a concentric circle, the circle is as large as before the injection molding machine template hole, after the ring set in, can guarantee the mold gate location and nozzle position is consistent.

- Q:What is a molds? What is the difference between die and die?

- Modular fixture is called the tooling and fixture, because most of products molding need processing after coming out, which requires on the machine processing, and on the machine requires fixture, so we in the assessment for the production of a product when they need to evaluate how much need to do the modular fixture, name.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Preform Plastic Molds Injection PET Moulding Top Level

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords