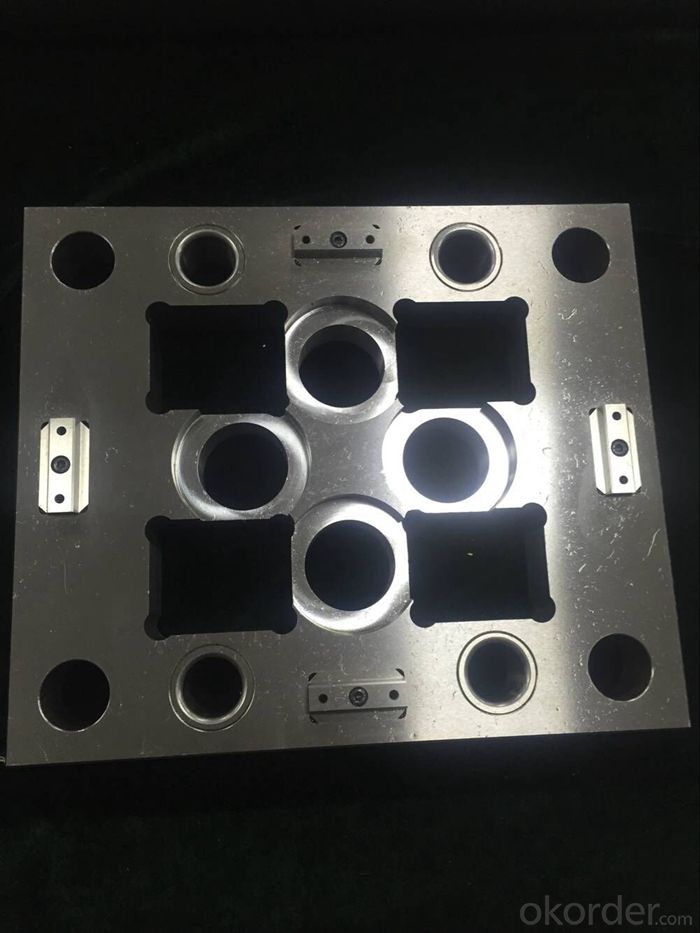

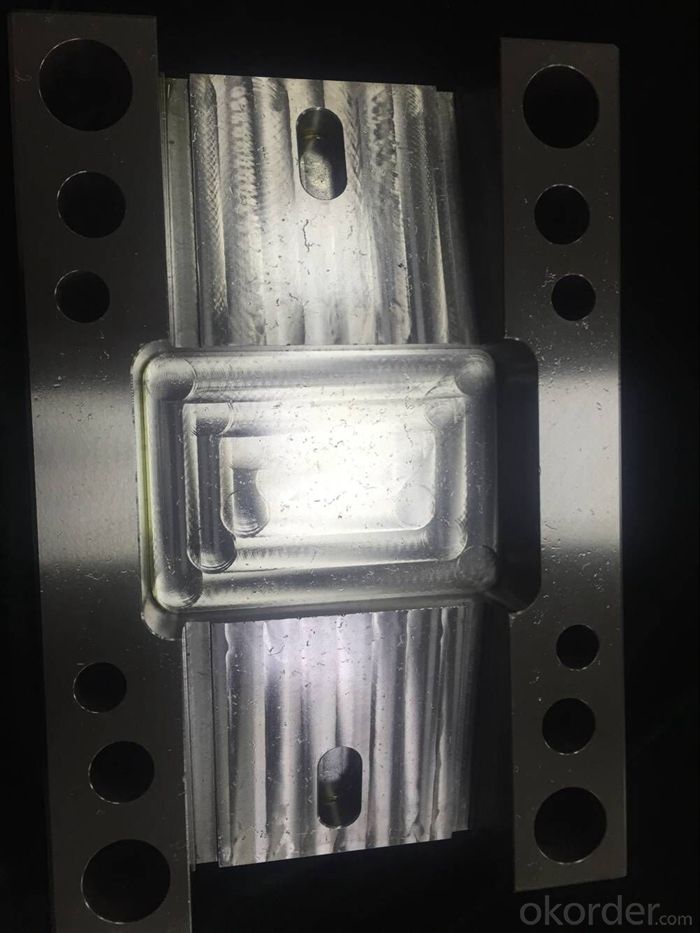

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:What type of mould is the tooling

- Mould: the definition of industrial production to injection molding, blow molding, extrusion, die casting or forging molding, smelting, the methods of stamping, stretching products of various molds and tools required. In short, the mold is used for molding tool of the item, it consists of various parts, mainly by the changes of the molding material physical state to implement items shape processing.

- Q:What is a mold, and what is a mold

- Under external force, the material is made into a special shape and dimension. Widely used in cutting, forging, cold heading, extrusion, powder metallurgy parts suppression, pressure casting, as well as engineering plastics, rubber, ceramics and other products of the molding or injection forming. The mold has a certain contour or inner cavity shape, and the shape of the blade can be separated by the shape of the outline. The inner cavity shape can be used to obtain the corresponding solid shape. The mould usually includes two parts: the moving model and the mold (or the punch and the concave), which can be divided into two parts. When apart, take out the pieces and put them into the mold cavity forming. Mold is a precision tool, complex shape, bear the expansion force of billet, the structural strength, stiffness, surface hardness, surface roughness and machining accuracy have higher request, the development level of mold production is one of the important symbol of the levels of mechanical manufacturing. There are many kinds of molds, according to the processing object and the processing technique can be divided into: the mould of processing the metal. The mould of non-metal and powder metallurgy. Including plastic mold (such as injection mould, die mold and extrusion die), rubber mould and powder metallurgy mold etc. According to the structural characteristics, the mould can be divided into flat blanking modes and spatial modes. The mould is usually single, small batch production.

- Q:Would you please tell me what the difference in the mold Tooling and mold

- Please say on the injection molding product is marked: 5200 is the mold material is 5200 or what?

- Q:What is the difference between mould injection and blow molding?

- Blow molding: also call hollow blow molding, a kind of development rapid plastic processing method. Thermoplastic resin by extrusion or injection molding of plastic parison tube, hot (or heated to softening state), put in split cavity, mold closing immediately after ventilation with compressed air within the parison, make plastic parison swell and clingy wall in the mold, the cooling mold release, the products have all kinds of hollow. Blown film manufacturing technology on the principle and hollow blow molding is very similar, but it does not use the mould, from the perspective of classification of plastics processing technology, molding process is usually included in the extrusion of blown film. The blow molding process was used in the production of low-density polyethylene small bottles during world war ii. In the late 1950s, with the development of high density polyethylene and the development of blowing and molding machine, blow molding technology was widely used. Hollow containers can be up to thousands of litres, some of which are computerized. It is suitable for the plastic polyethylene, polyvinyl chloride, polypropylene, polyester, etc., and the empty container is widely used as an industrial packaging container.

- Q:Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q:What is the material of hot pressing die?

- Die steel must have sufficient hardness and abrasion resistance, sufficient strength and toughness. With good machining performance and good decorative pattern, it is commonly used for carbon alloy steel. Commonly used in Japan, yk-30, yellow card 55CC, which is generally used in the factory state, is better after processing.

- Q:Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- In the case of the building Lord, all the moulds have a lot of wind, which is that the injection molding machine is not enough

- Q:What does a factory do?

- The mold factory is to make the mold, the stamping injection moulds what It also has milling and heat treatment

- Q:The processing method of the mold cavity processing center

- The common processing procedure of the cavity: (milling) around and on both sides, the thickness remains 0.4 minus 0.6rnrn. Two sides of the face and two sides of adjacent side, the surface roughness Ra is 0.8 mu m. The shape of the fitter and the position line of the screw hole. The pattern required the milling out of the cavity, the unilateral remaining balance of 0.3 one-half mm, The machine drill screw holes, thread and so on. 6. Heat treatment. The electrode is used in a rough machining cavity. The worker finishes the polishing. The design calls for chrome plating, etc. The equipment was repaired and inspected.

- Q:What is a mold bite

- Make pattern, can make the surface of product surface and cavity surface can hold a small amount of air, do not form vacuum adsorption, make it easy to get out. Anti-skid, anti-roll, good handle. To make hemp or subsurface, prevent light reflection, eliminate eye strain and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords