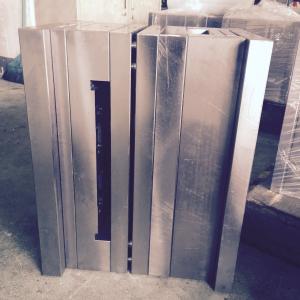

Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

This product USES S50C material.Accessories are all made of standard guide pin guide bush.The thickness tolerance are processed according to the requirements of 0.00 to 0.02.High surface finish and roughness of standard.Heat resistance and corrosion resistance is very strong, It is used in plastic mold development and manufacturing,composed of various steel plate with parts,It is a complete set of the mould size to make it easier for mold into the injection molding machine installation.specific parameters according to customer requirements.

Specifications

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base,mould base, LKM standard mould base, HASCO standard mould base, DME standard mould base, LKM mould base, HASCO mould base

What We Do

Plastic Injection molds. tools making Clear acrylic Injection molding Prototyping and model making Plastic Printing & Welding & Assembly Product 2D&3D design.Reverse-engineering.etc

What We Believe

High quality is the only factor we consider Innovation reduces the cost,increase capacity One-stop solution assures the satisfaction of customer.

We expert in development and fabrication of various high quality moulds with advanced technology and tooling equipments.

High-speed CNC machine Engraving machine Mirror EDM machine Milling and Grinding machine Slow W-EDM machine

We provide one-stop solution from drawings design to final parts

PMMA.ABS.PP.PC.PS.PBT.etc Injection machines equipped with robots Feeders & Dryers. Temp. controlers Assembly line with silk-screen & painting

Advanced CAD and CAM software is adopted in the tool making process.Operated by our experienced engineers.

Moldflow Pro-Engineer Solidworks Unigraphic Auto-CAD

Pictures of the mould base:

- Q:What is the difference between the electric casting mould and the CNC working mould

- Electroforming mould cavity is electricity casting processing, is to do a the same electrode and the product shape, with a thick layer of metal plating electroplating way, down to do mold cavity, general decorations in this process. CNC is also called processing center, which is the direction of computer control tool, which can be processed into very complex shapes, most of which are processed in this way

- Q:What is a compression mold?

- The main equipment used in compression moulds is press and mold. The most commonly used are self-contained hydraulic presses, which range from dozens of tons to several hundred tons. Have lower pressure press and upper pressure press. The molds used to compress moulds are called press moulds, which are divided into three categories. Overflow mold, semi-overflow mold and mould. The main advantage of the compression mould is that it can be moulded by larger planar products and mass production, and its disadvantages are long production cycle and low efficiency.

- Q:How does the die rod work? Is it through the press?

- The device in the upper module is called a push device. It is flexible and rigid, and its purpose is to remove the shock and waste from the concave mold. It is widely used because the rigid push device is strong and reliable.

- Q:What is the "KO hole" on the injection mold?

- General mould, the greater the KO hole design of the KO hole, the more it but the location of the KO hole mold must be according to the plunger position of injection molding machine is used to open, or mould thimble can't top up!

- Q:How many types of molds? Please help me out!

- The classified method of plastic mold profile at 11:30 on Friday November 7, 2008 mold is one of the important technology and equipment, modern industry is an integral part of many industrial products production. After China's accession to the WTO, the ability to attract foreign investment increased year by year, the increasingly prominent position, to become the world manufacturing factory of all kinds of industrial products mold imports more and more. The type of mold is usually carried out in accordance with the process of processing object and different classification, from the industry point of view to see the distinction between the main plastic mold, rubber mold, metal cold punching mold, metal cold extrusion die and hot extrusion die, metal drawing dies, powder metallurgy mold, metal die-casting mold, metal precision casting die mold, glass, glass fiber reinforced plastic mould and so on. Although there are many kinds of molds, the main items in the tax classification are the items of the tax items 84.80 and 82.07. The following is a description of how different types of molds used in the most common plastic processing are described. Plastic forming method of the most common general divided into two categories: the melt molding and solid phase is melt molding plastic heat to above the melting point, make the molten forming way, belongs to the molding methods of molding process mainly include injection molding, molding (shrinkage) molding, extrusion molding, etc; Solid-phase molding refers to a type of forming method in which plastic is kept solid under molten temperature

- Q:How many kinds of equipment can be used to open the mould?

- The molds have a lot of equipment Most basic: lathe, milling, grinding machine, line cutting, drilling machine These are the most basic. And, of course, you need to press the bed for the test

- Q:What is the role of the grooves in the guide column

- Storage of lubricating oil and cutting groove action. Because of the relative motion of the guide when the guide is working, because the clearance is small, the oil can be scraped off for a long time. So the design of this groove allows the lubricant to stay on the length of the guide column, not all of it to the end. Because the processing accuracy is different on both sides of the guide. Level 2 orientation precision, for example, sliding guide part of guide pillar and guide bush of requirement is H7 / h6, guide pillar of the fixed part and the mold base with the mounting holes is H7 / s6, relief groove guide pin can be divided into two sections, one section for h6, another for s6, so relief groove is a must have!

- Q:What do you mean by the side of the plastic mould

- When the mold is in place, the main view can see the top of the board.I hope my answer will help you.

- Q:What is a mold bite

- Make pattern, can make the surface of product surface and cavity surface can hold a small amount of air, do not form vacuum adsorption, make it easy to get out. Anti-skid, anti-roll, good handle. To make hemp or subsurface, prevent light reflection, eliminate eye strain and so on.

- Q:The wall thickness of the die is affected by the plastic parts

- Wall thickness is high, thin wall is not enough, The wall is not uniform, and the stress concentration is deformed The thin wall is easy to hold, fill insufficient, the process is difficult to adjust, poor high

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords