Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

Cavity, core and screw neck of steel adopt imported S136 in Sweden, and be heating treatment of hardness up to HRC48-50.

All moulds base do heat treatment of hardness up to HRC 30-35.

Advanced mould design technology:

a) Each cavity self-locks independently and using high precision JAPAN CNC SYSTEM.

b) To ensure low decent ration & precision of the product.

c) Each mould spare part be inserted with durable parts, which are interchangeable. d) In order to improve and achieve high production efficiency, we always design the best cooling system and can match a cooling machine for each mould.

Advanced & accurate valve hot runner & temperature controller, ensure reliability of production and high transparency & brightness of product.

Mould sliding use copper, bottle be achieved FOOD SECURITY standard, and mould life guarantee more than 3 million shots.

2. Main Features of Multi-Cavities PP Preform Mould

No. of Cavity | 12 Cavity | 16 Cavity | 24 Cavity | 32 Cavity | 48 Cavity | 72 Cavity |

18g(cm) | 60*37*43 | 74*37*43 | 80*50*45 | 76*60*48 | 102*60*55 | 110*86*58 |

Weight(kg) | 625 | 770 | 1300 | 1650 | 2500 | 4100 |

28(cm) | 60*37*45 | 74*37*45 | 80*50*48 | 76*60*52 | 102*60*58 | 110*86*62 |

Weight(kg) | 655 | 810 | 1310 | 1800 | 2690 | 4450 |

40(cm) | 60*37*48 | 74*37*48 | 80*50*50 | 76*60*55 | 102*60*62 | 110*86*65 |

Weight(kg) | 700 | 860 | 1360 | 1900 | 2880 | 4670 |

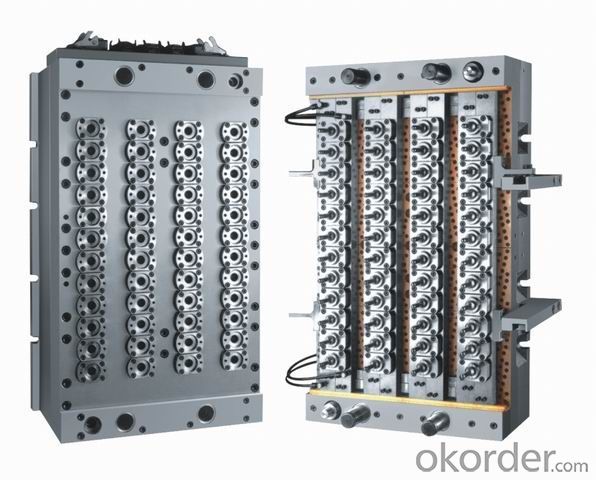

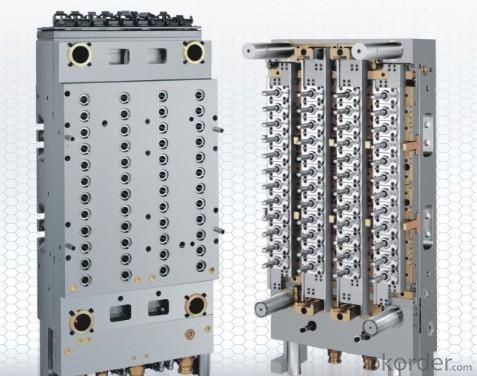

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:The stamping dies at the Angle of 90 degrees, the Angle is big or small how to repair.

- That r Angle is on the bend and it's still on the bend. ? On the bend.I hope my answer will help you.

- Q:Make cell phone lens what mould material is best! ?

- If the usual spray -- the thunder carving process and the die life of less than 500,000 people can take the NAK80 to do. The best way to do this is by Palmax. Therefore, it is recommended to use: S136, D - star, palmax, of course, the material price high If you use NAK 80 I knew it must be small factory, on the key material object cost that is not a wise move

- Q:What is replicas in the mold

- Hello, due to the product production problem, need to increase the number of mold to achieve production, requires several or more of the same set of mold to produce, so many die relative to development is a copy of the first set of mould.

- Q:What is the difference between a mold and a handboard?

- Although there are so many differences between planks and mould, but they still have contact, generally use hand-board model to the customer to confirm the shape first, confirmed to open mold production. The cost of many physical molds is generally high, with large molds valued at 100,000 or even millions, especially in the medical industry. If there is a structural unsound or other problem in the process of installing the die, it will be very large. The handboard model can solve the problem of this loss, reducing the risk of making physical models.

- Q:What is the "KO hole" on the injection mold?

- General mould, the greater the KO hole design of the KO hole, the more it but the location of the KO hole mold must be according to the plunger position of injection molding machine is used to open, or mould thimble can't top up!

- Q:How do you handle the die holder

- Mould run burrs this directly associated with the precision of the mould processing 1: CNC processing aspect: parting surface machining with rubber products separately, do protect with mold clamp mouth out at the same time, avoid direct cause in the process of machining die round 2: split electrode aspects: faceted clear Angle of electrode to product rubber electrode, separately die fillet in the EDM process can be avoided

- Q:What does a factory do?

- The mould is used with die casting mould plastic mould. Most of the articles around you except paper are very wide open

- Q:The difference between wire cutting and mold making

- (4) test and test. Because of the characteristics of the mould and the experience of mould design, the mould must pass the test or the test pressure after assembly, and finally determine whether it is qualified. At the same time, there are some parts that need to be tested to be finalised. Therefore, there must be a certain testing period for the production schedule. (5) the machining of molds to mechanization, elaboration and automation. At present, the demand of product parts for mould accuracy is higher and higher, high accuracy, high life, high efficiency and more and more. The machining accuracy depends mainly on the precision of machine tool, the processing technology condition, the measuring method and the method. At present, precision molding grinding machine, CNC precision surface grinding machine, precision CNC wire-cut edm machine, precision continuous trajectory coordinates grinder and the use of three coordinates measuring machine is becoming more common, mould processing to the intensive development of high and new technology.

- Q:What is the mold for?

- As mentioned before, the plastic forming theory and mathematics modeling is not perfect, caused by stamping process analysis and formulation in the design phase is not perfect, need bench late a large number of debugging, this problem may be irremediable solution for, still can reason to evade a responsibility appropriately for designers, but the mechanical structure of the mould level is not good, for the kind of "line", as if we would be a little difficult to quit the effect, of course, I think it's also have many causes. First of all, the more high-end mold mechanical structure generally applied in complex parts and processes, such as car side plate, wing plates, engine hood pressing parts, such as domestic auto manufacturers due to many reasons such as sino-foreign joint venture, it is difficult to make the domestic mold enterprise manufacturing this kind of product of mold, new models of similar parts is often deprived, so we seldom opportunities for actual combat, some powerful manufacturers can be less in production tasks, practice habits conducted theoretical design, heaven knows earth knows the final effect is people do not know!

- Q:What is a mold bite

- Make pattern, can make the surface of product surface and cavity surface can hold a small amount of air, do not form vacuum adsorption, make it easy to get out. Anti-skid, anti-roll, good handle. To make hemp or subsurface, prevent light reflection, eliminate eye strain and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords