Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

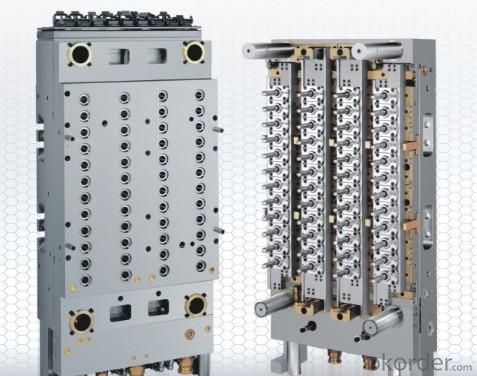

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

PET Preform Injection Molding from 1-cavity for wide mouth jar and gallon bottle perform up to 72-carrow neck perform mold; Tube blank is designed with the help of computer, which surely contributes to the increasing of yield of bottle;

Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independently to ensure low decentration of product;

Core and cavity are made of special mold steel after preheating treatment in the original factory in Sweden. Individual tempera-ture control of each cavity;

Lip cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The excellent hot runner design assures uniform heating and improves greatly of the plastic product quality;

No cutting of gate is employed to reduce the labor intensity;

Standard inter-changeable mold components;

The life of mold is more than 3 million times.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:In die mold, is it better to use UG or PROE? That's a quick one. Is it convenient?

- UG is a hybrid model that can be partially parameterized (and, of course, fully parameterized), which is good for the model update. PTC is completely parameterized, edit update small design (home appliances), large (planes, cars), however, does not crash, the refresh time will affect the designer's idea. Comparison 9: talk about the conversion of format! UG core PARASOLID is generally supported by more than three dimensional software! Only the PROE insist The most simple! The most commonly used software is MASTERCAM, which can only be turned through raw IGES or STEP

- Q:Make cell phone lens what mould material is best! ?

- Use the S136 vacuum to make sure you're talking. Besides the quality of the material, the polishing process is also very heavy, the material will be burned with orange peel

- Q:What is the difference between the electric casting mould and the CNC working mould

- CNC handicraft processing and die processing are not very different from the processing method, it is the processing medium, the fine carving, the numerical control car and some nc processing equipment. It's very different from being processed. Hand processing mainly processing polymer materials, such as PC, ABS plastic and nylon, and so on, take the massive material carving milling polished lacquer after forming, the final products are generally full scale model of customer research and development, do good as future product identical in appearance. The purpose is self-evident, it is for the product to have a visual confirmation of the shape, color and match of the product before the model, reduce the risk of open mode.

- Q:What does the mold slow wire do

- Walking wire electrode is used copper wire, fast wire with molybdenum wire, and fast wire is used in reciprocating, slow wire can only be a one-off, slow silk machine, of course, price is high, the processing fee is high also, processing product quality is high

- Q:What certificate does the mold major need to take an examination?

- (1) AutoCAD is a software that is easy to learn and can be used as a basis for CAD, which is software for almost everyone in the industry. This is a two-dimensional software that doesn't have to learn its so-called 3-dimensional function because it's basically not used for 3-d purposes. Once you've learned the software, you can stay at this stage and learn one of the two 3-dimensional software. (2) the Pro/E (weak) design function, programming (3) the UG (design aspects as Pro/E, but programming function is stronger) which of the two 3 d software to learn. If you want to improve your mold design ability, consider taking part in a training session. After training, you will be able to get a real job.

- Q:How many kinds of equipment can be used to open the mould?

- The molds have a lot of equipment Most basic: lathe, milling, grinding machine, line cutting, drilling machine These are the most basic. And, of course, you need to press the bed for the test

- Q:Is there any way to keep the ice from sticking to the mold and remove it from the mold

- The general mold is made of plastic, catching both ends and turning in the opposite direction

- Q:Why does the mold exhaust, so where does the gas come from

- Just add a little bit of the purpose of the exhaust: burn. The other ten is perfect.Plastic mold venting is not good, the gases in the cavity is compressed, produce a lot of pressure, this is the back pressure to prevent the molten plastic for normal rapid molding, make it difficult to injection molding. Once injection molding difficulty in this case, the researchers often adopt the method of improve the injection pressure of injection, this led to the pressure maintaining prolonged, molding cycle delay, the production efficiency is lower, injection molding machine energy consumption increases and so on. Even corrosive gases are sometimes fouled in the cavity, contaminating plastic molds, reducing the life of the molds and increasing the cost of plastic moulds.

- Q:What is the top of the die?

- The top block of the mold is supported by the support, the whole plate is not solid, it consists of the frame, block, block and so on. The top block is part of the system of the top of the mold. Commonly used in injection moulds. Injection mold is a tool for making plastic products. It is also a tool that gives full structure and precise size to plastic products. Injection molding is a kind of machining method used in batch production of some complex parts. This means that the material that is melted by heat is injected into the cavity of the cavity, and it is cooled and solidified, and it is formed. The molding mould is divided into thermo-plastic mold and thermoplastic plastic mold. In accordance with the molding process is divided into the mold, blowing mold, casting mold, hot forming mold, extrusion mold (mold), injection mould, etc., the thermal model can be divided into the overflow type material overflow way, half overflow type, not overflow type three, injection mould was pouring system can be divided into two cold runner mold, hot runner mould; It can be divided into movable type and fixed type by means of loading and unloading.

- Q:What is suitable for moulding steel

- Plastic moulds include thermoplastic moulds and thermosetting plastic moulds. The plastic mould requires certain strength, hardness, abrasion resistance, thermal stability and corrosion resistance. In addition, it also requires good manufacturability, such as heat treatment deformation is small, processing performance, corrosion resistance, good repair welding, grinding and polishing performance is good, good performance, high roughness, good thermal conductivity and working conditions have stable size and shape, etc. In general, the injection molding or extrusion die can be used for the heat making die steel. Hot solidification and the requirement of high wear-resisting and high strength mold can be used in cold making die steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches