PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

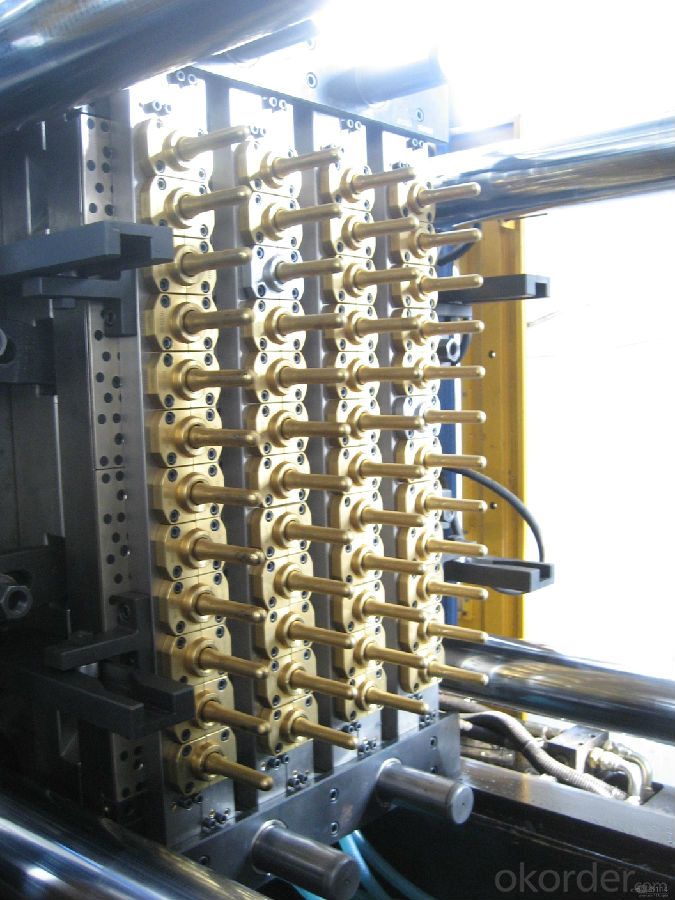

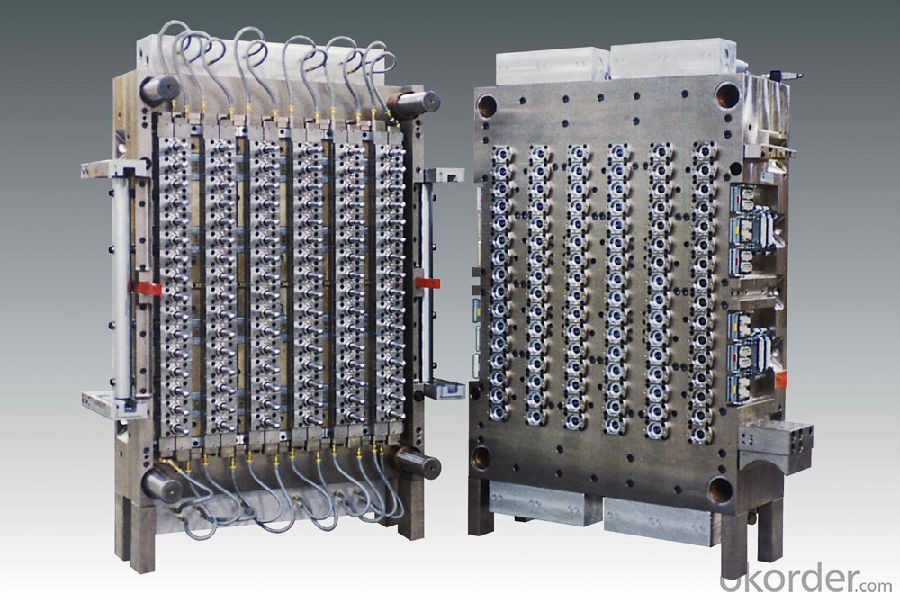

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Mould structure

Advanced structure is designed to improve rate of finished products;Two-step double taper locating technology;The each cavity is self locked independently with the core.The off-center adjustment system make the perform thickness error less than 0.05mm.Bottleneck is adopted International Screw thread standard, No cutting of gate to reduce the labor intensity

. Material of steel

Cavity and core use stainless steel 2316 with fine polishing,high hardness to get mold's high precision and good quality. mechanical treatment cavity and core to prolong service life,nitrogen treatment with neck screw.with fitly operation,guarantee Long using life over 2 million shots of injection cycle

.About gate system

Pin-valve gate,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

.About hot runner

The hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mould parts.we use the double heating system,it has separate temperature control mode ,the heat bar are used to heat the mould mainfold plate,small heaters supply the heating temperature for cavity nozzle continuously.

.Cooling system

Each parts including core ,cavity and valve gate has independently cooling system.

.special satisfied servive

Each mould undergoes strict mould test before delivery.we can provide an experienced team for installation and test as per client's request Standard inter-changeable mould components

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

The company can provide full no-man bottle preform product line, which includes injection machine, mould robotic arm and moulds.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:The application of hydraulic cylinder in mould

- There are a few moulds that need to be pumped into the core, embedded, and unmoulded, most of which are used in hydraulic cylinders. There are some special molds that can be opened for material or material. There are also molds that can be used alternately, and also used in hydraulic cylinders. In the design of the mould, it is usually involved in a short range of linear motion, if the device is using a hydraulic system, the designers mostly use hydraulic cylinder devices.

- Q:What is the relation between the mould and the clamp

- How to say, big is all belong to the mechanical industry, say to the relation, I personally think to make the mold to be able to make a fixture, do jig not necessarily can make the mold. The mold needs more experience, and the fixture needs more creative thinking. The common fixture is non-target, but the mold is not the standard, but is roughly the same type. Such as stamping die of blanking die, the structure is basically all the same, just in the middle of the blanking shape, templates, fixed plate, stripper plate up and down, up and down mold core, unloading spring, guide pin guide sleeve is involved. There are many different types of jig, but the key is to locate and clamp these two core ideas. Well, I hope it works for you.

- Q:What is the cooling system of the mold

- It is in the core that makes the channel for cooling water flow. The effect is to ensure that the mould has a reasonable temperature balance in the process of production.

- Q:How does the die rod work? Is it through the press?

- The device in the upper module is called a push device. It is flexible and rigid, and its purpose is to remove the shock and waste from the concave mold. It is widely used because the rigid push device is strong and reliable.

- Q:What is the design philosophy of the mould?

- The design and fabrication of precision volumetric mould and die life.

- Q:Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- If solve the above problem is mould itself reason, please use red lead to mold fitting well, the original poster check mold in touch wear, wear a location, see if cooperate in place.

- Q:How expensive are the molds, or how expensive are they? Which quality is better?

- The molds are more expensive. But efficiency is doubled, and if it's big, it's a lot of work. The quality is better.

- Q:What effect is the flange of the die

- Flanges are concentric with the jw, flanged, and the nozzle of the injection-molding machine, the flanged design corresponds to the size of the machine. You've seen the big hole in the injection molding machine. That's a match for the flange

- Q:The wall thickness of the die is affected by the plastic parts

- Wall thickness is high, thin wall is not enough, The wall is not uniform, and the stress concentration is deformed The thin wall is easy to hold, fill insufficient, the process is difficult to adjust, poor high

- Q:Basic knowledge of die fitter

- 4. The fitter species along with the development of mechanical industry, the widening scope of work bench, professional division of labor is more thin, so is divided into ordinary fitter fitter (assembly fitter), repair bench, die locksmith tools (bench) and so on. (1) the general fitter (assembly bench) is mainly engaged in the assembly and adjustment of machinery or parts, and the clamping of some parts. (2) the repairman mainly engages in the maintenance of various kinds of machinery and equipment. (3) tool fitter (tool manufacturing fitter) is mainly engaged in the production of moulds, tools, measuring tools and samples. 5. Fitter basic operation skills including line, chisel cut cut cut (), sawing, drilling, reaming, counter boring, reaming, tapping and set of silk, straightening and bending, riveting, scraping, grinding, and basic measuring skills and simple heat treatment, etc. Either fitter, first of all should grasp the fitter in all kinds of basic operation skills, and then according to different division of labor further study to grasp the good parts of the bench processing and assembly of products and equipment, repair and other skills. Fitter skills require strengthening basic skill practice, strict requirement, standard operation, practice and innovation. Basic operation skills are the basis of production, is the basis for the machinist's professional skills, therefore, must first master, can be achieved step by step in the future work with ease, with ease.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords