Lead Rail

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 1000000 Pieces per Year pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

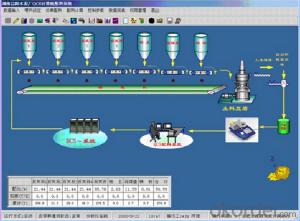

Detailed Product Description

lead rail,guide way:

can accord customer's require to produce.different.size.diffrent design

lead rail,guide way:

1.material:iron

2.certification:CE

3.size:can basis on customer's requirement

- Q:Is hydraulic guide oil the same as gear oil of reducer?

- It's better to separate. The two oils come in different ways

- Q:When the control cabinet, 35mm installation of the guide rail to the control panel when the installation of screws, how many M?

- If it is a linear guide rail, 35 of the guide holes are: bore diameter 14, depth 12, through hole 9

- Q:Do the analysis with ADAMS. When you add contact force, you need stiffness and damping. Do you know?..

- Machine tool guide and slider materials, gray cast iron, precision machine tools, CNC machine tools or ball screw guide, more use of steel guide

- Q:Machine tool linear guide bearing?

- Different specifications, weighing is not the same,

- Q:First ask why the potential difference between the metal rod in the guide rail 0

- In the title, the metal rail resistance does not count.So CD is short circuited. That is, U (CD) =0 V

- Q:The linear guide rail is used under water. Besides stainless steel, what else can be used to prevent rust?

- Simple is to grease, but it will rub off.Then you can wire other metal on the surface of your rail, but the cost is high.These two methods of choosing matters that are more relevant to your situation.Ohmic anode protection method two upstairs man said, I think your guide under the water.

- Q:How can the dovetail guide be fixed on the case?

- Dovetail groove guide is more complicated and can not be automatically compensated after wearing. It can be adjusted by one insert. It is compact in size and easy to adjust. Fixed on the box, to use: if you want to adjust the angle, can be installed as a small turret lathe, plus a rotary, T type screw fixation; if you do not need to adjust the angle, can be fixed with six angle bolts, and then hit the two taper pin, to ensure accurate positioning.

- Q:What are the advantages and disadvantages of the V type guideway used in machine tools?

- The comparison and analysis of the type of machine tool guide rail, the most common form of guideway on the steel guide rail is the steel guide rail, and its use has a long history. The steel guide rail is a fixing element of the guide rail system, whose cross section is rectangular. The utility model can be horizontally arranged on the machine bed of the machine tool, and can also be cast into an integral body with a lathe body, which is respectively called a steel inlaid type or an integral type. The steel insert is made of steel, hardened and ground. The hardness is above 60 degrees of Rockwell hardness, and the steel guide rail is attached to the surface of the machine bed or with the Lapping Column by screw or binder (epoxy resin) to ensure the optimum planeness of the rail. This type of service is easy to maintain and easy to replace. It is very popular with maintenance workers.The integral guide rail or the casting guide rail, namely the steel rail and the base are cast into a whole, after processing, then fine grinding to the required size and finish. The guide rail must be quenched by flame to increase the surface hardness, so as to improve the wear resistance of the rail. The bed is generally of ductile iron, nodular cast iron hardness than steel, the whole rail can re repair and hardening, but it is almost impossible to replace.In order to achieve the above purpose, machine tool manufacturing practices in the past usually is: edge design of steel rails have hooked "ears", in the base of the mold casting, steel rail arranged on the base, then the molten iron poured into the mold, so that the steel rail and the base are integrally cast.

- Q:Rails, sliders, things. I want to find them directly in toolbox. Is there anything in SolidWorks2007?

- Download plugins, such as Shindy parts libraries, are very useful. With rails and gears, motors.

- Q:The difference between guide rail and slide rail

- The linear guide rail is a general designation, including slider and track. A device, such as a groove or ridge, made of metal or other material, capable of bearing, fixing, guiding, moving a device or equipment, and reducing its friction. A longitudinal groove or ridge on the surface of a guide, used for guiding and fixing machine parts, special equipment, instruments, etc..The guide rail, also known as linear guide, linear slide rail, for linear reciprocating movement, linear bearings have higher than the rated load, and can bear a certain torque, can achieve high precision linear motion under high load.The motion of the linear guide rail is used to support and guide the moving parts and reciprocate in a given direction. According to the nature of friction, the linear motion guide can be divided into sliding friction rail, rolling friction rail, elastic friction rail, fluid friction rail and so on. Linear bearings are mainly used in automation machinery, more like German imports of machine tools, bending machines, laser welding machines, and so on, of course, linear bearings and linear shaft is used together. The linear guide rail is mainly used in the mechanical structure with higher precision requirements, and the moving element and the fixing element of the linear guide rail are not made of intermediate media, while the rolling steel ball is used.

We believe in the purchasing policy of "try our best to bring your cost down". If you plan to purchase goods to reduce your cost, please let us have a chance to quote at your needs. We are capable of providing you with a profitable proposal with assurance.Hope we can build long-term and good business relationship.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China |

| Year Established | 2010 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America 9.41 South America 5.88% Eastern Europe 10.59% Southeast Asia 4.29% Africa 6.06% Oceania 5.88% Mid East 4.88% Eastern Asia 5.12% Western Europe 8.24% Central America 5.06% Northern Europe 12.94% Southern Europe 7.94% South Asia 10.18% Domestic Market 3.53% |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Sydney,Angeles,Singapore |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English, Chinese, Spanish, Russian |

| b)Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Lead Rail

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 1000000 Pieces per Year pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords