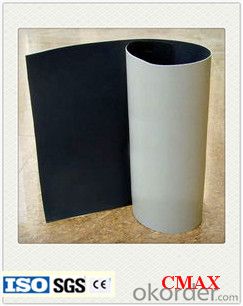

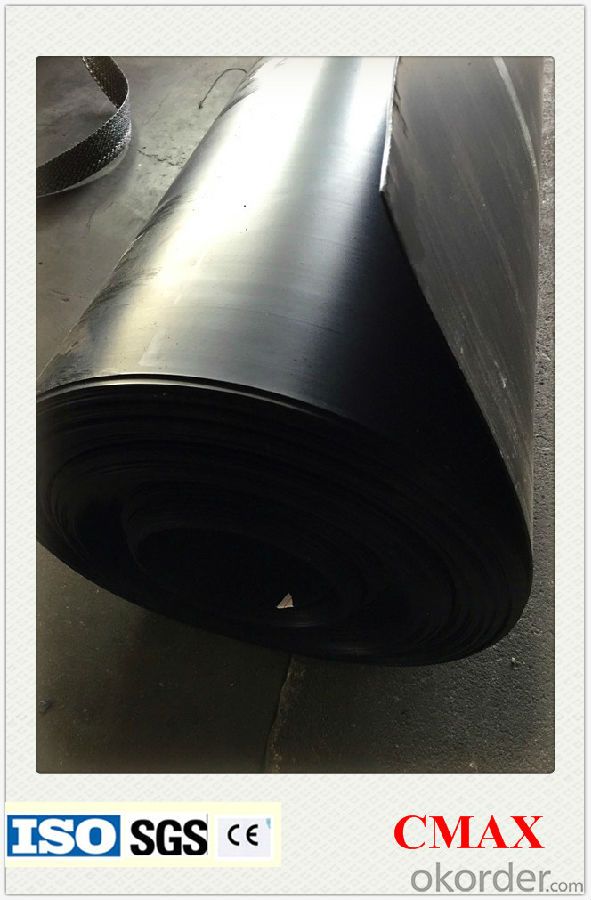

LDPE/HDPE/LLDPE Geomembrane with Thickness 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

LDPE/HDPE/LLDPE Geomembrane with Thickness of 0.1mm-3.0mm

Geomembrane Description

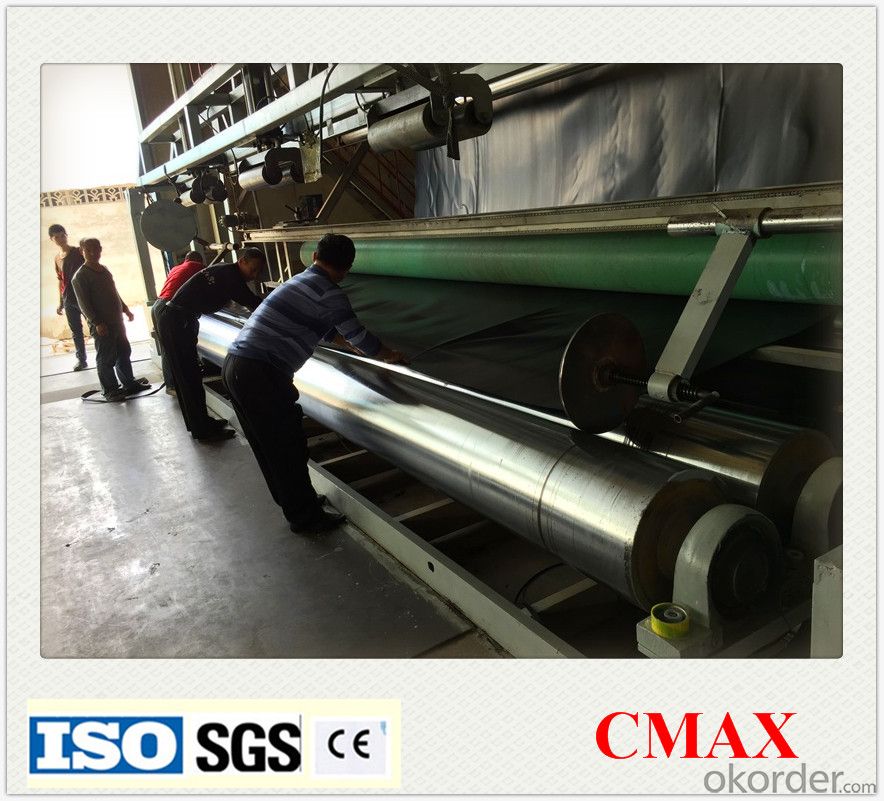

Geomembrane is made from LDPE, LLDPE, HDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Geomembrane Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Geomembrane Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Geomembrane Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How to choose glossy and matte geomembrane used in refuse landfill ?

- Hope it is easy to understand because it is not complicated at all. Actually, the dfference between matte and glossy membrane is the coarse surface, which is to increase friction. I f it is for refuse landfill, there are mainly three parts needed geomembrane for seepage-proof. reservoir bottom, side slope and cover (or closure). For "reservior bottom" , pave a layer of imported glossy geomembrane at the bottom of the landfill for horizontal seepage prevention. For side slope, use matte geomembrane around the landfill to increase friction because the side slope has vertical angle, that is, to make the geomembrane hung on the side slope. For cover or enclosure, use glossy membrane for horizontal seepage prevention to prevent rain pouring into the reservior and percolate increasing and isolate the garbage in landfill from the outside. It may not be comprehensive, but from practical experience coorperated with Canada Solmax Inc. Hope it's helpful.

- Q:Where are construction geomembrane in ash dam?

- Geomembrane and other geotechnical materials are fixed with anchoring ditch in the middle of side slope. There are construction team and welding equipments.

- Q:Is waterproof geomembrane the same as EPDM?

- Not the same, different material

- Q:Can geomembranes be used for irrigation canals?

- Yes, geomembranes can be used for irrigation canals. Geomembranes provide an impermeable barrier that prevents water seepage, reducing the loss of water through seepage and increasing irrigation efficiency. Additionally, they help in controlling the flow and distribution of water, preventing erosion and maintaining uniform water levels in the canals.

- Q:Can geomembranes be used in water storage tanks?

- Yes, geomembranes can be used in water storage tanks. Geomembranes are impermeable liners that can be installed in tanks to prevent leakage and provide a barrier between the stored water and the surrounding environment. They are commonly used in various water containment applications, including water storage tanks, to ensure the integrity and safety of the stored water.

- Q:How to deal with the dust in the mobile phone film?

- 1, If you know how to open the shell, you can do it yourself. Open the shell, and then clean up the dust inside. Finally, you should be careful not to leave fingerprints on it when you open the shell. If there is after-sales service, you can go to consult. How to deal with the dust in the phone screen? 2, If you can not open the shell or be afraid that you open the shell but cannot install it, you can go to a special place to clean the dust. It can repair the general mobile phone. You can learn to repair when others help you, you will not have to find someone else to help in the future.

- Q:What are the codes for acceptance of constructional quality of concrete structures?

- 1, improve basic provisions of acceptance. 2, add provision of inspection lot expansion of certified products or continuous qualified products. 3, delete provisions for acceptance of template deismantle. 4, add provisions for acceptance of moulded rebar and other rebar new technologies. 5, add provisions for acceptance of unbonded prestressed steel fully enclosed waterproof performance. 6, improve provisions for site acceptance of premixed concrete. 7, , improve provisions for site acceptance of precast components. 8, add provisions for acceptance of objects which has deviation in structures position and dimension. 9, add a method of checking structural entity concrete strength through rebound-drilled core method.

- Q:What is the method of installing screen protector for PSP?

- Don't be in a hurry when getting the film, clean up the screen of PSP to wipe out the dust, then prepare a card (or an ID card). Then prepare some diluted liquid detergent (that is, the mixture of water and a little detergent). The purpose of preparing it is to lubricate, then a napkin is also needed. Start when all the preparation is done, you can paste the screen. Drip a few drops of liquid detergent on the wiped PSP screen. The tear off the adhesion surface of the film, gently cover on the water, then rub the water till it is apread between PSP and film. If you only use water, you will find it difficult to rub. After the completion, rub the film to the correct position, and the first step is done. There must not be too much water in the process, or it is easy to be rubbed to the button on the edge. The next step is the essential. We use the card to remove the water starting from the middle of the film. We should pay attention that when removing the water, it will be blown out from the film, then use the napkin to absorb the water. The purpose is to avoid the water enter the button, then you can remove the bubbles inside. Repeat it and after a while the water will certainly be removed, and then check that if there is any bubble, and if there is, remove it. After removing the bubbles, the film will fit your PSP exactly, then you can paste the two films on the sides by the same method. Now all you have to do is to wait the water between the film and PSP evaporate, and after the evaporation you will be happy to see the effect. I want to explain why we use detergent. There are two reasons: first it is colorless, second it plays the role of lubrication. So it is very important to use it, and the water between the film and the PSP will not leave traces.

- Q:How do geomembranes prevent soil contamination in oil and gas industry applications?

- Geomembranes prevent soil contamination in oil and gas industry applications by acting as a barrier between the soil and potential contaminants, such as oil, gas, and chemicals. These synthetic liners are impermeable, preventing the migration of pollutants into the soil and groundwater. They effectively contain any spills or leaks that may occur, reducing the risk of contamination and protecting the surrounding environment.

- Q:How do geomembranes contribute to erosion control in riverbank stabilization?

- Geomembranes contribute to erosion control in riverbank stabilization by acting as a barrier between the river water and the soil. They prevent the water from directly eroding the soil by providing a protective layer. This helps in maintaining the stability of riverbanks and reducing the potential for erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE/HDPE/LLDPE Geomembrane with Thickness 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords