Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG300-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 673-980g

Clamping Force: 3000 kn

Opening Stroke: 570 mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Plastic Rubber Injection Moulding Machine

Warranty: One Year

Material: Stainless Steel

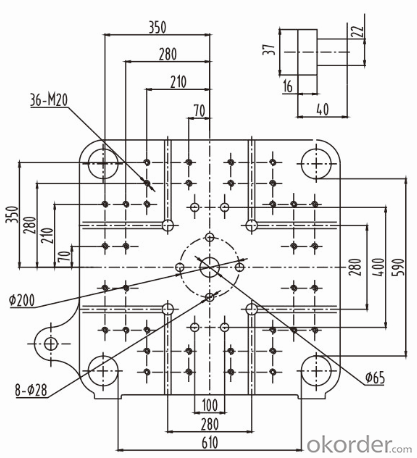

Space between Tie Bar: 610*590

Screw Diameter: 58-65-70 mm

Machine weight: 9.1T

Ejector stroke: 160mm

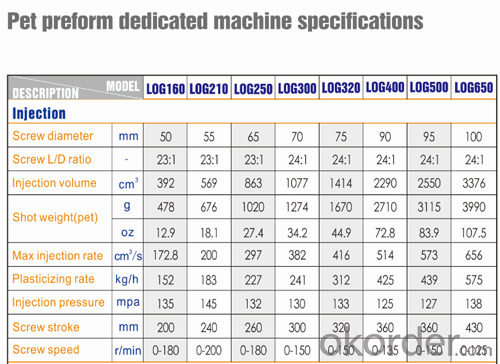

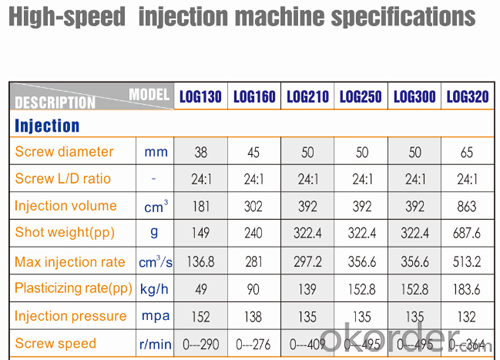

| Description | Unit | LOG-300A8 | ||

| international recognized models | 1400/300 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 740 | 929 | 1077 |

| Shot volume | g | 673 | 845 | 980 |

| Oz | 23.5 | 29.5 | 34.2 | |

| Screw diameter | mm | 58 | 65 | 70 |

| Injection diameter | mpa | 190 | 151 | 130 |

| Screw L:D ratio | 24:01:00 | 22:01 | 20:01 | |

| Scerw steoke | mm | 300 | ||

| Screw rotate speed | r/min | 0-150 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3000 | ||

| Opening stroke | mm | 570 | ||

| Platen size | mm*mm | 870*850 | ||

| Space between tie bars | mm*mm | 610*590 | ||

| Maldthickness | mm | 200-600 | ||

| Platen Mix stroke | mm | 1170 | ||

| Ejection stroke | mm | 160 | ||

| Ejcetion force | kN | 77 | ||

| Power/Elcetric Heating | ||||

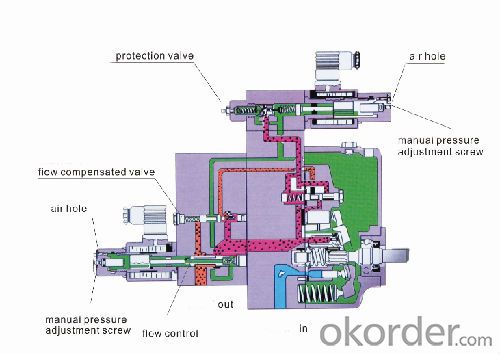

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 29 | ||

| Heating power | kw | 23.6 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5 | ||

| Tank volume | L | 380 | ||

| Machine dimesions | m*m*m | 6.4*1.6*2.18 | ||

| Weight of machine | kg | 11000 | ||

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

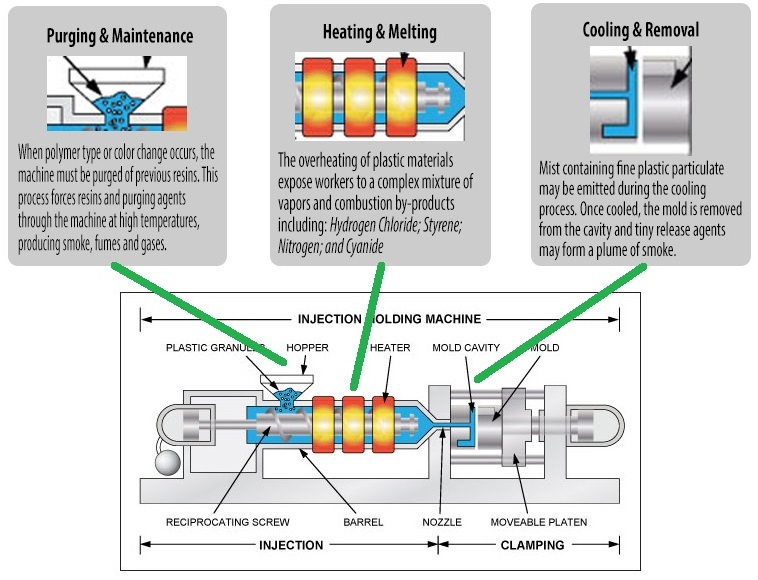

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

- Q:How to check the mold opening stroke of injection molding machine

- 1. the maximum opening stroke of injection molding machine has nothing to do with the die thicknessMainly refers to the clamping mechanism for injection molding machine with hydraulic machinery, such as XS-Z-30, XS-Z-60, XS-ZY-125, XS-ZY-350, XS-ZY-500, XS-ZY-1000 and G54-S200/400 type injection molding machine, the mold opening stroke by the connecting rod mechanism (or clamping cylinder) determines the maximum stroke, irrespective of the thickness of the mold.For injection mold with single parting surface:Smax = H1+H2 + mm (5 ~ 10)For injection mold with double parting surface:Smax = H1 +H2 + +a (5 ~ 10) mmType: Smax injection molding machine maximum mold opening stroke (mm);H1 plastic parts (mm, H1) launched a distance - like mold core is equal to the height, but for the plastic parts of the inner surface is stepped, sometimes do not have to launch the full height core can remove the plastic parts, then H1 can be determined according to specific circumstances, in order to successfully remove the plastic parts;H2 a piece of plastic height, including the height of the castable (mm) of the gating system that is connected to the plastic part.A the distance between the fixed die seat plate and the runner plate required by the casting system to remove the condensate (mm).

- Q:What is the meaning of injection molding machine before melting and pumping and after melting? What's the function of 10?

- Injection molding machine melting process is through the rotation of the screw, the material inside the bucket through the screw to the front end of the screw rod propulsion, screw rotation is not only itself active back, when the barrel material is pushed to the front end of the screw in the front of the barrel, the pressure will be more and more, will be forced to retreat when the screw, screw back the set position, the screw stops rotating, melt end. In order to prevent the pressure in the barrel is too large but the glue flows out from the nozzle, usually used to pumping (also called loosening, cable, shot back down), the active screw back a certain distance (usually a few mm) to remove part of the pressure.

- Q:How does the injection machine prevent the product from sputtering to the machine? As for the question, how can I solve it perfectly?

- It's time to slow down. Is it a launch rocket? It's too vigorous. Not really. Just use a cardboard file

- Q:Automation has to be done at the present time when labor costs are going up sharply,

- At present, there are many kinds of injection molding machines on the market, and it is a very realistic problem how to select the suitable manipulator in so many kinds of mechanical hand. For the factory technicians who want to apply the manipulator, the manipulator needs to choose from the following aspects: first of all, the understanding of the tonnage of the existing injection molding machine. Different tonnage injection molding machine corresponds to the template size and height of the safety door of different sizes, the template size directly determines the mechanical hand travel, safety door height affects the product from the mold to the mold is smooth out, the two key dimensions determined to consider how the payload of the manipulator is not enough, the weight of injection molding products.

- Q:Seek advice! Is there a better low-pressure injection molding machine? After the sale well, which friends can introduce, thank you!

- Let me introduce you to a good oneChasing the answerAs far as I know, the low pressure injection molding machine produced by Connie Technology Co., Ltd. is especially good and provides full range of technical support, which is rich in New Technology

- Q:What an elder brother knows how nitrogen injection is going on. What should I pay attention to?

- 1. the operator must undergo good safety education.2. operate strictly according to the operating rules of equipment.3., when the valve operation, wear protective equipment: masks, gloves, etc., to prevent frostbite.4. check the safety valve and pressure gauge once a year, check the riot film every two years, check and record the records.5. when the nitrogen emissions, people should stay away from the drain, otherwise, long time suffocate easily.6. in the obvious place to hang around the nitrogen tank "trespassers", "dangerous" and other warning signs.7. freezing on nitrogen pipe, no heavy blow.8. check the nitrogen tank every day and find the problem in time.9. always keep the nitrogen tank clean and free of oil and grease.10. equipment should be cut off for a long time without gas.

- Q:What brands of injection molding machines are there in Taiwan?

- Taiwan brand molding machine a lot of ah, there are at least dozens of brands, relatively well-known: Taichung, Taiwan Zhenxiong, quanlifa, fuqiangxin, Nan Rong, Hua Ronga and so on, what you want to buy a machine? What's the requirement of your product?

- Q:Consult the injection machine and say how many grams, but I also see "360T 250T", what does this mean? Thank you

- Injection molding machine on the subject of its clamping force, the general 1T can be understood as 1 grams.

- Q:General injection molding machine agents need what conditions?

- See what brand you agent, big manufacturers brand trouble

- Q:How will the screw speed of injection molding machine be adjusted slowly?

- Injection molding machine screw speed, first, adjust the injection molding machine pre molding pressure and flow, and then adjust the back pressure

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords