injection molding machine LOG-160S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Other | Style: | Horizontal |

| Brand Name: | LOG machine | Model Number: | log-160s8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 260-368g |

| Injection Rate: | 122-172g/s>122-172g/s |

| Clamping Force: | 1600kn | Opening Stroke: | 430mm | ||

| Power(W): | 27.6kw | Certification: | CE ISO9001 | After-sales Service Provided: | Engineers available to service machinery overseas |

| Color: | design by onself |

Packaging & Delivery

| Packaging Details: | 20GP |

Product Description

LOG-160S8 SPECIFICATION

International size rating 525/160

INJECTION A B C

Shot volume cm3 277 318 392

Shot weight G 260 298 368

OZ 9.1 10.5 12.9

Screw diameter mm 42 45 50

Injection pressure mpa 190 166 135

Screw L:D ration 20:1 20:1 18:1

Screw stroke mm 200

Screw speed(stepless) r/min 0-200

CLAMPING UNIT

Clamping force kn 1600

Opening stroke mm 430

Platen size mm×mm 680×680

Space between fie bars mm×mm 460×460

Mold fhickness(Min-Max) mm 180-500

Max.daylingt mm 930

Hydraulic ejection stroke mm 140

Hydraulic ejection force kn 50

POWER UNIT

Hydraulic system pressure mpa 17.5

Max.motor current A 64

Heating capacity kw 12.6

Number of femp confrol zones \ 4+ nozzle

GENERRL

Dry-cycle fime Sec 2.0

Oil fank capacify λ 210

Machine dimensions m×m×m 4.95×1.25×2.0

Machine weight kg 5300

Certifications

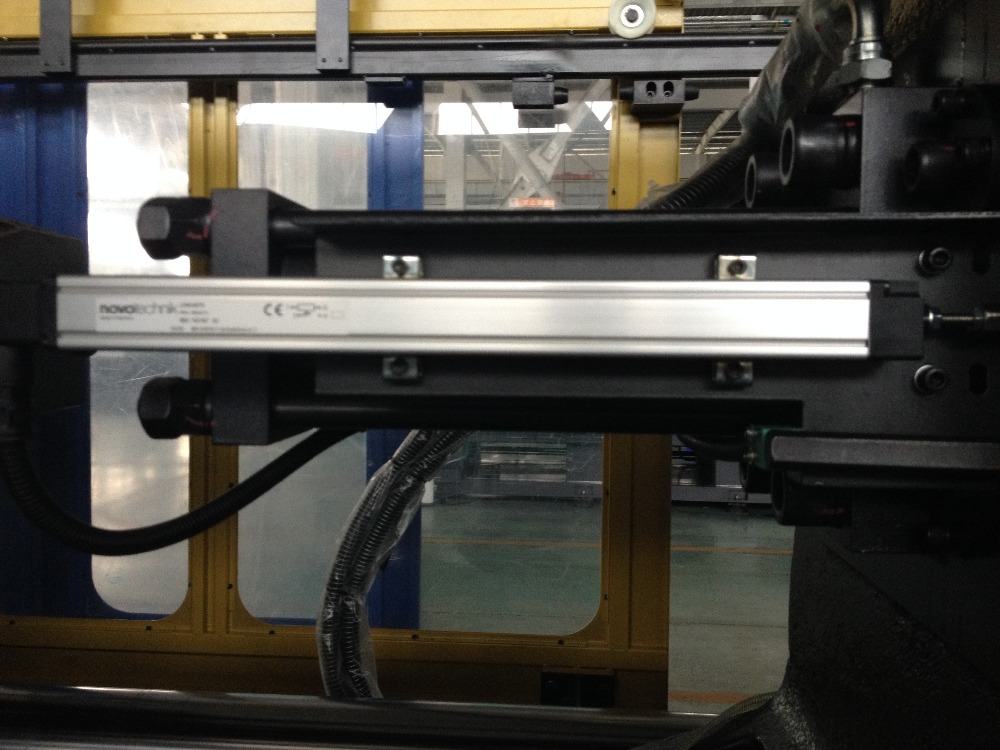

Detailed Images

Pre-Sales Service

Packing & Delivery

Packaging | |

Size | 4.95(M) * 1.25 (M) * 2.0 (M) |

Weight | 4720KG |

Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

- Q:Relative to the size of the installation mold, it can also be said to be the internal column or guide column of the injection molding machine. How can this part be translated in English?

- Tie Bars--- pull rod (Ge Linzhu)Clearamce Between Tie Bars is the column spacing is between the Green column, you said the distance, Green column spacing also restricted the installation of the width of the mold, the mold width must be less than the Green column spacing can be put under the lock on shot out!

- Q:How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

- Q:List of injection molding machines

- Nippon Steel JSW, NISSEI and NISSEI the United States UBE Ube brand: Cincinnati CINCINNATI domestic or Hong Kong and Taiwan: Haitian, Zhenxiong, Jia Ming, Donghua and so on.

- Q:Does the injection machine have to use cooling water?

- Three. The temperature difference of the ice water at the inlet and outlet of the mold is usually set according to the requirements of the product. In many cases, the temperature difference is 3-5 degrees centigrade, which is ideal, but sometimes the temperature difference is 1-2 degrees centigrade. The smaller the temperature, the greater the amount of ice water required to bring out the same amount of heat, and the less needed traffic. For example: when the temperature difference is 5 degrees centigrade, the flow rate needs 60L, but when the temperature difference is 2 DEG C, the flow rate needs 150L.Four, ice water flow: a pair of mold required water flow directly with the mold to take away the heat and ice water and the temperature difference between the mold. For example: 6480 kcal / h heat from the die away, if the temperature is 3 DEG C, water flow Q=6480 / 3 / 60=36 (L / min).Five, water temperature of cooling fluid (water): mould temperature is generally subject to the processing of materials and products shape changed greatly, such as polystyrene thin beaker, die ice water temperature at 0 DEG C; and in most cases, the mold required ice water in the temperature of 5 DEG C, a full function of cold water can provide the above 5 degrees of ice water, cold water can meet the low temperature type intelligent temperature below 5 DEG and 0 DEG C requirements. The connection between the water cooler and the mold is usually connected with an enhanced hose, because the hose itself has the function of heat insulation, but the length is more than 5m, and it should also consider moderate thermal insulation.

- Q:What is the back pressure in the injection molding machine?

- Back pressure: screw back when applied to the rod end of rubber pressure. It can reduce material consumption and bubble phenomenon.A: when the back pressure is adjusted properly, the density of the melt can be increased, the air discharged by the air in the cylinder can be discharged, and the rubber material is compacted, so that the cycle of the beer mould is stable, and the production efficiency is improved.B: back pressure is high, screw speed is slow, the resistance is large, the barrel screw is easily damaged, because the screw friction heat, heat increase in external heating unchanged, will make the temperature rise, the viscosity decreased, resulting in leakage and countercurrent flow, the nozzle is easy to produce salivation phenomenon.C: low back pressure and screw speed is fast, but it is difficult to put the rubber barrel compaction, the particles is not uniform, resulting in flower phenomenon, such as adding toner material will appear in different shades of color.Note: feed back when the screw rotation should be shaped, injection should be straight. 1, can melt inside the barrel compaction, increase density, improve the stability of injection quantity, weight and size of the products.2. The gas in the melt can be extruded to reduce the gas, the inner bubbles and the gloss uniformity of the products. Slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon.3, slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon.4, appropriately increase the back pressure, can improve the product surface shrinkage and product periphery walk glue situation.

- Q:when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- PVC for the temperature requirements are very strict, the back pressure is small, hard PVC temperature can not too low at about 170-190, too low, but not good, there is a delay melt, namely the screw does not move after injection, on the verge of opening a few seconds before time began to melt, melt after 10 seconds to stop the opening of concrete how much time delay according to the time you began to melt cooling and temperature control, there is a nozzle to just not cured so far, should not be too high. This basically can control the temperature, can be controlled within 8 degrees.

- Q:Adjust the speed of injection molding machine screw speed is what role?

- Should not be too fast, too fast will make the production of products decline, surface defects and so on! Usually between 270_350 transfers!Trouble to adopt, thank you!

- Q:Not transformer. It's wires and meters. Because the transformer is public. If 10 kilowatts is not enough. How much is enough?

- 160t injection molding machine, electric power and motor power in about 25 KW. As well as auxiliary machine: 50kg drying hopper, about 4.5kw. If it is hot runner mold hot runner power in 8-15kw (see details) mold temperature machine power is about 6kW that gives you power far enough. Injection molding machine production, power is about 60% of the rated power, or 15KW. So, if only drive 160T machine, do not deserve any auxiliary machine, at least 15KW.

- Q:Injection molding machine outjected products should be red, why will change

- Reasons: 1., the cylinder is not clean, 2. molding temperature is too high, 3. toner is not resistant to temperature, or raw material forming temperature and toner temperature inconsistent. I hope I can help you......

- Q:What is the injection molding machine back pressure, back pressure role is what?

- Adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

injection molding machine LOG-160S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords