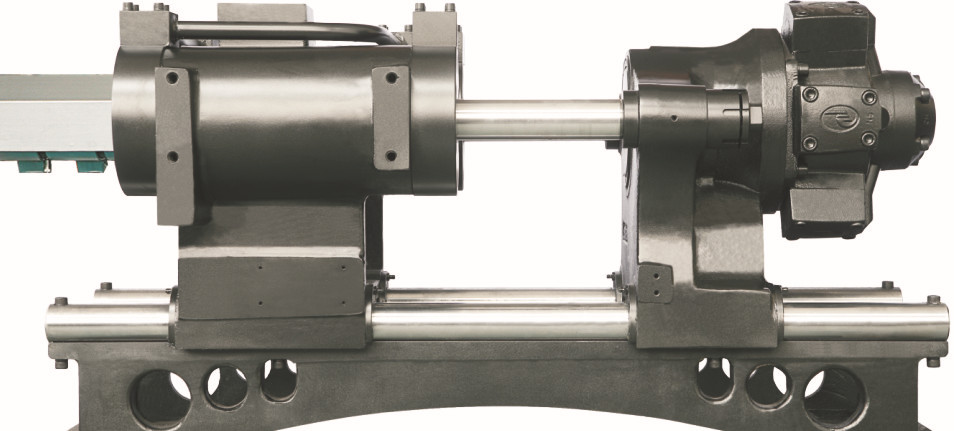

Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 650S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 2488 |

| Clamping Force: | 6500kn | Opening Stroke: | 920mm | Power(W): | 29+29kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-650S8 Technical parameters

Description | Unit | LOG-650S8 | ||

international recognized models | 4640/650 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 2160 | 2734 | 3376 |

Shot volume | g | 1966 | 2488 | 3072 |

Oz | 68.8 | 87.1 | 107.5 | |

Screw diameter | mm | 80 | 90 | 100 |

Injection diameter | mpa | 215 | 170 | 138 |

Screw L:D ratio | 23.6:1 | 21:1 | 19:1 | |

Scerw steoke | mm | 430 | ||

Screw rotate speed | r/min | 0-125 | ||

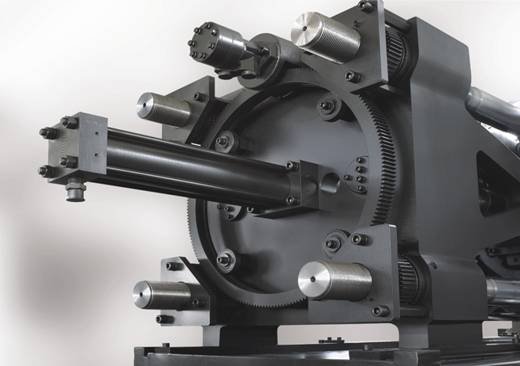

CLAMPING UNIT | ||||

Clamping force | kN | 6500 | ||

Opening stroke | mm | 920 | ||

Platen size | mm*mm | 1320*1290 | ||

Space between tie bars | mm*mm | 930*900 | ||

Maldthickness | mm | 350-910 | ||

Platen Mix stroke | mm | 1830 | ||

Ejection stroke | mm | 265 | ||

Ejcetion force | kN | 182 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29+29 | ||

Heating power | kw | 51.6 | ||

Number of temp.conteol | 6+nozzle | |||

Other | ||||

Cycle time | sec | 6.0 | ||

Tank volume | L | 1500 | ||

Machine dimesions | m*m*m | 9.6*1.9*2.3 | ||

Weight of machine | kg | 36000 | ||

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q:How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The size of each of the products are different in nature, the machine method is not the same, increase the product I will generally use four, the first section of second section is walking the gate, go to watch it go gum products, is to prevent it, trapped gas or gas lines, third pressure faster than second some a little slower, the vantage point to almost full gum, last paragraph third paragraph is used as an outlet, the rate dropped to 10 or 15, the pressure to about 65, he shot to see which position began to pressure the pressure point is set to fourth position, if the material is difficult to shrink a good tune, put on three to Paul has shrunk, such as the first stage pressure 10, speed 15, 0.5 seconds, second pressure 20, speed 25, a second time, third pressure of at least 130 or more, the speed of not more than 45, at least 4 seconds If not, cut the amount of the first and second periods to control shrinkage. Of course there are sure to barrel temperature, mold temperature, get well, water or oil are related to important. I can answer that for you so far. Honestly, I've only been studying for 9 months so far. I've got everything to learn there. In fact, I want to be familiar with this line and practice more

- Q:The use of injection molding machines

- Servo energy-saving injection molding machine series, equipped with servo transmission power control system with high performance, in the process of injection molding machine in different flow pressure, make the output frequencies, and accurate closed-loop control of pressure and flow, high speed response and the best matching and automatic adjustment of the servo motor of the injection molding machine energy demand.1 、 using excellent servo controller, servo motor and other energy-saving devices.2 、 sensitive servo control system, quick start-up, reaction time is only 0.04S.3, servo motor and hydraulic system constitute closed-loop control, compared to the traditional model, the repeatability is greatly improved4, reduce the impact of the lock mold, and extend the service life of mechanical components and dies5, reduce the use of electricity, in the ideal working condition of the model than the traditional injection molding machine energy saving efficiency can reach 20%80%6, the system heat is much lower than the traditional injection molding machine, saving about 30% of the cooling water consumption, extending the oil seal and hydraulic parts life7, the whole line is running low noise, significantly lower than the traditional injection molding machine

- Q:Want to know how to play a complete product, how to calculate the pressure, speed, etc.. Example, GREE electrical appliances series 4002B chassis, how can I transfer the full product?.

- (3) adjustment of injection device;1) adjust the injection seat moving stroke after the die is closed and at low pressure, so that the nozzle can top the mold gate sleeve.2) check whether the nozzle used for the processing of materials, installation is smoothly, the nozzle flow is smooth.3) adjust all kinds of pressure, such as injection pressure, packing pressure, injection seat pressure, back pressure, etc..4) adjust the metering stroke and anti trip stroke of the screw, and check whether the limit switch or sensor is sensitive and reliable.5) the pre plastic screw air several seconds, to have no abnormal mechanical noise, hopper opening plate switch is normal.

- Q:Can polyurethane (PU) material be molded by injection molding machine?

- Certainly.Range of melting point of polyurethane 204-232CProcess control temperature 196-232CGeneral polyurethane injection molding temperature 200C, high temperature resistant 250CPolyurethane molding is divided into one step, two steps, and if it is two step molding, that is, the preparation of prepolymer, then injection molding, if it is a one-step method of direct alcohol or fat and the reaction of a unique acid, then the use of casting.

- Q:How big is the minimum injection molding machine?

- Industrial products, minimum injection molding machine, about 12-15 grams [injection volume]If used in scientific research, it can be made specially,

- Q:Automation has to be done at the present time when labor costs are going up sharply,

- At present, there are many kinds of injection molding machines on the market, and it is a very realistic problem how to select the suitable manipulator in so many kinds of mechanical hand. For the factory technicians who want to apply the manipulator, the manipulator needs to choose from the following aspects: first of all, the understanding of the tonnage of the existing injection molding machine. Different tonnage injection molding machine corresponds to the template size and height of the safety door of different sizes, the template size directly determines the mechanical hand travel, safety door height affects the product from the mold to the mold is smooth out, the two key dimensions determined to consider how the payload of the manipulator is not enough, the weight of injection molding products.

- Q:How much is the ejection rate of injection molding machine?

- Under normal circumstances, 3---10 almost, special when the special appropriate tune

- Q:Which country was the injection machine invented in?

- In 1958, the first injection molding machine was born in Shanghai, and opened a new page of our own plastic machinery. But the injection molding machine produced at that time was of low technical content, and could only use general plastic to produce daily necessities with lower technical requirements, such as plastic boxes, plastic barrels, plastic basins, etc.. With the development of petrochemical industry in China, China's plastics machinery industry has gradually formed an independent industrial sector, and a certain scale, is an important part of the national machinery industry, especially since the reform and opening up, China's plastics machinery industry has been considerable development.

- Q:The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- you still go to find a professional book, check the good, this to make a mistake, lost your face.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-650S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords