Injection molding machine LOG-1100S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG-1100S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 5403 |

| Clamping Force: | 11000KN | Opening Stroke: | 1150mm | Certification: | CE |

| After-sales Service Provided: | Engineers available to service machinery overseas | BIG shot weight: | energy saving |

Packaging & Delivery

| Packaging Details: | one machine in three 40GP containers |

| Delivery Detail: | 45days |

Product Description

Product performance and advantages:

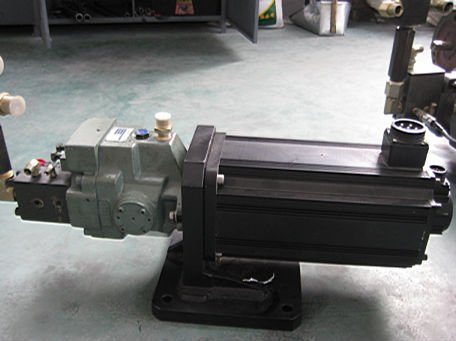

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in

comparison with conventional hydraulic injection molding machines. The response speed has been obviously

increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-1100S8 Technical parameters

Description | Unit | LOG-1100S8 | |||

international recognized models | |||||

injection | B | C | D | ||

Tjeoretical injection volume | cm³ | 4123 | 4989 | 5938 | 6968 |

Shot volume | g | 3751 | 4540 | 5403 | 6340 |

Oz | 132.8 | 160.8 | 191.4 | 224.5 | |

Screw diameter | mm | 100 | 110 | 120 | 130 |

Injection diameter | mpa | 220 | 182 | 153 | 130 |

Screw L:D ratio | 24.2:1 | 22:1 | 20.2:1 | 18.6:1 | |

Scerw steoke | mm | 525 | |||

Screw rotate speed | r/min | 0-110 | |||

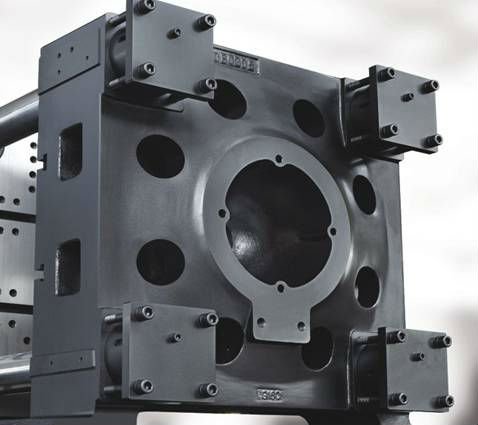

CLAMPING UNIT | |||||

Clamping force | kN | 11000 | |||

Opening stroke | mm | 1150 | |||

Platen size | mm*mm | 1650*1650 | |||

Space between tie bars | mm*mm | 1150*1100 | |||

Maldthickness | mm | 450-1200 | |||

Platen Mix stroke | mm | 2350 | |||

Ejection stroke | mm | 350 | |||

Ejcetion force | kN | 270 | |||

Power/Elcetric Heating | |||||

Hydralic system pressure | Mpa | 17.5 | |||

Pump motor | kw | 44+44 | |||

Heating power | kw | 58.85 | |||

Number of temp.conteol | 6+nozzle | ||||

Other | |||||

Cycle time | sec | 10 | |||

Tank volume | L | 2300 | |||

Machine dimesions | m*m*m | 12.5*2.8*3.5 | |||

Weight of machine | kg | 60000 | |||

- Q:What does injection mean?

- The injection is heated into molten plastic particles by fluid pressure system, using the machine (per square cm/176kg) injected into the pre designed closed mo (closed mold cavity is) after cooling to obtain the required products ` ` release process.This is the principle of injection molding

- Q:Injection machine code

- Jiaming computer: 1688.Good view of the computer: 0000, the password is not used to adjust the model, press the "memory" button on the panel.Changxin computer: 753159168899. Otherwise: any four digit + (hour + bit +1) + (+ + bit +1) + any four digit numberNISSEI: 2227777; Sumitomo machine code: 0434201474, 7777. Friends and computers: 16885858.Best computer code: 16883297. Huada computer: 9595, level one password: 0697, four level code: 2010,Toyo universal code: 9422345, Jinfeng computer: 70648415. LS password 159753 or 083191;QC WER-MRN-52813458 is a Xintianji interval number can't be wrong, Taiwan guanpin password: 2233, universal password is: WIN-MRN-52813458Computer: 002004006 Century Fox, bampr computer: the first is: 0769, the two level is 2417755

- Q:Name of China's top ten famous brand injection molding machines

- Jun Chun injection molding machine,Department of Chun machinery main products: Toyo FANUC injection molding machine, injection molding machine, injection molding machine, steel Sadegh, NISSEI injection molding machine, injection molding machine, double color injection molding machine, side injection unit.

- Q:Debugging and debugging process of injection molding machine

- Causes and solutions of plastic forming defectsIncorrect operating conditions, damage to the machine and mold will cause a lot of molding defects, the following provides some solutions for reference. In order to reduce down time, reason and can find out the operation problem as soon as possible, the operator should put all the best record in the condition of injection type injection molding condition record table, for days after the reference for problem solving.(1) the finished product is incompleteFault reason handling methodThe plastic temperature is too low to increase the temperature of the fuse tubeThe injection pressure is too low to increase the injection pressureThe amount of injection is not enoughWith the nozzle with the sprue bushing is plastic spill to re adjust its coordinationThe shot time is too short to increase the injection timeThe injection speed is too slow to accelerate the injection speedImproper adjustment of low pressureMold temperature is too low to improve mold temperatureThe mold temperature is uneven, the mold pipe is re adjustedThe exhaust of the mould is not proper, and the proper exhaust hole is installed at the proper placeThe nozzle temperature is not low, and the nozzle temperature is increasedUnequal opening of mold to re release the mold overflow positionThe sprue or overflow is too small to enlarge the sprue or overflowPlastic lubricant does not increase lubricantBack pressure is insufficient, slightly increase back pressureRubber ring, adhesive screw wear, removal, inspection and repairInsufficient injection capacity, replacement of larger specifications of injection molding machinesThe product is too thin and use nitrogen spray

- Q:Why should the central feed system be used in the injection molding workshop?

- First, the central feed system is automated, can save people, facilitate management, improve production, and now it is not easy for enterprises to recruit individuals, and each enterprise wants to find the best employees.Second the central feeding system has many advantages such as visual, raw materials, recycling materials in switching (material) by mixing, drying, color and so on.Third, the central feeding system integration, reduce workshop covers an area, can make workshop cleanliness and beauty enhancement, and promote enterprise image

- Q:How to choose an injection molding machine

- Study, but the injection molding machine structure, mold cooling and oil cooling system, this is also very important, this is related to the normal operation of the equipment, how to choose this match, injection cooling system selection, I can help you solve!

- Q:What is the function of the temperature control box of the injection molding machine? Thank you

- Controlling the temperature of two heating tubes.Chasing the answerThe temperature is too high and too low, the thermostat plays the role of switch heating tube power supply.The heating tube is used to warm the mold

- Q:What are the main parts of an injection molding machine?

- (3) hydraulic system hydraulic transmission system is to realize the injection molding machine according to the process of the various actions required to provide power, and meet the injection molding machine parts of the pressure, speed, temperature and so on. It is mainly composed of each kind of hydraulic component and hydraulic auxiliary component, in which the oil pump and the electric motor are the power source of the injection molding machine. Various valves control the oil pressure and flow rate to meet the requirements of the injection molding process. (4) the electrical control system, the electrical control system and the hydraulic system coordinate reasonably, may realize the injection molding machine craft process request (pressure, temperature, speed, time) and each kind of procedure movement. Mainly by electrical appliances, electronic components, instruments, heaters, sensors and other components. Generally there are four kinds of control, manual, semi-automatic, automatic adjustment.

- Q:The temperature of the injection molding machine: 1 220.2 210.3 200.4 190.5 175 period, when heated, everything is normal, but when the temperature reaches the set value of the motor work, work to about 15~20 minutes, 3 and 4 of the temperature began to rise slowly to 213~220 (lead injection unstable), other Dan normal. Then the motor is switched off, stop, about 15 minutes later, the 3 and 4 section temperature began to slowly fall to the set value, please master: what is the reason? How to solve?

- Hello:You can lower the feed rate a little, and there is a big wear on the material and the cylinder.

- Q:What is the injection molding machine back pressure, back pressure role is what?

- When the screw is in the process of feeding, as the amount of material inside the barrel increases, forcing the screw back, and the control of its back speed is called back pressure, back pressure can increase the density of plastics, melting better

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-1100S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords