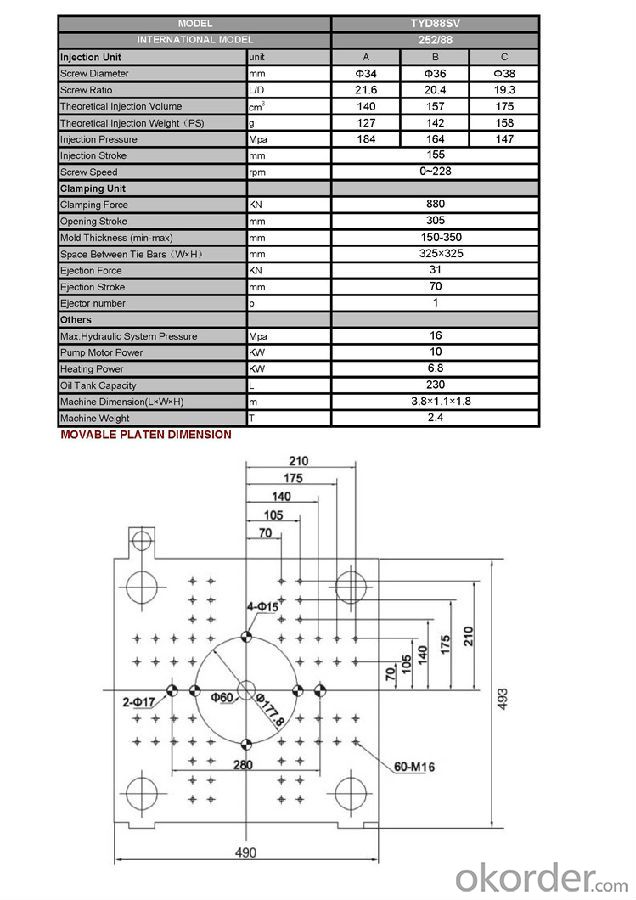

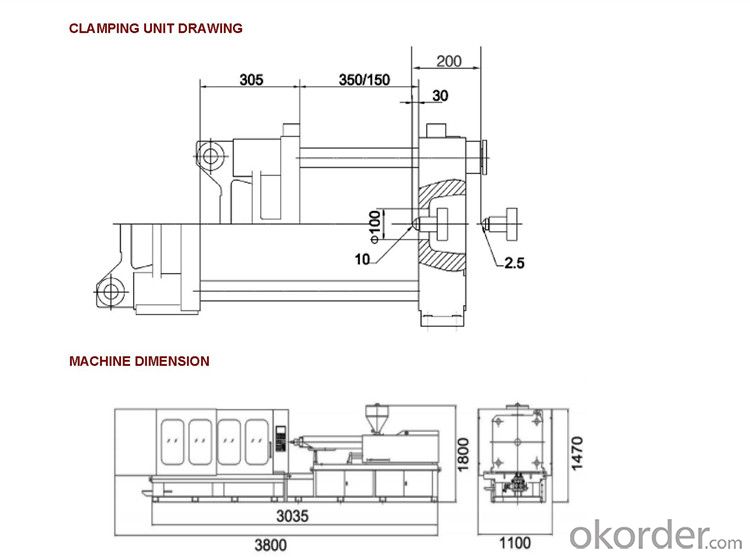

88T plastic injection molding machine TYD88SV plastic making machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

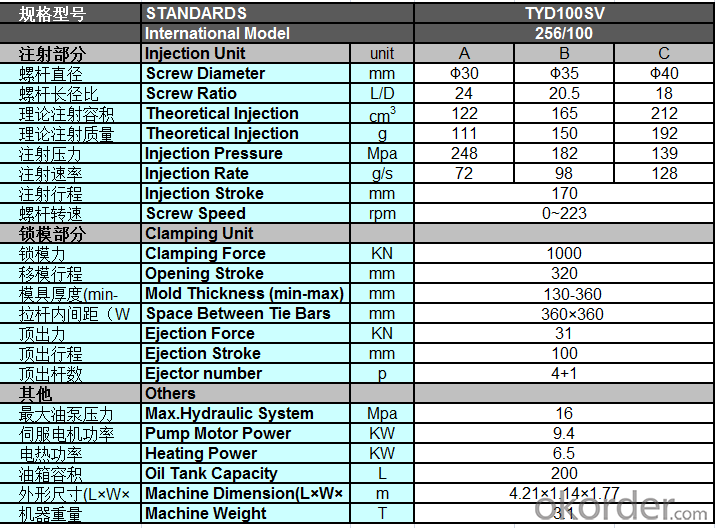

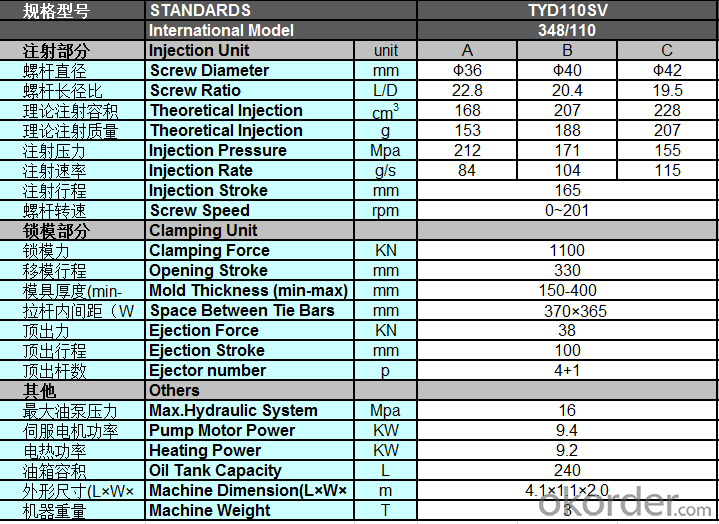

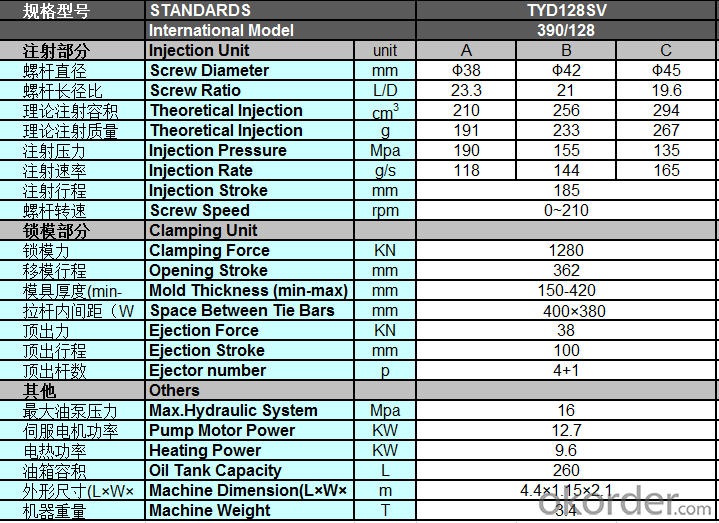

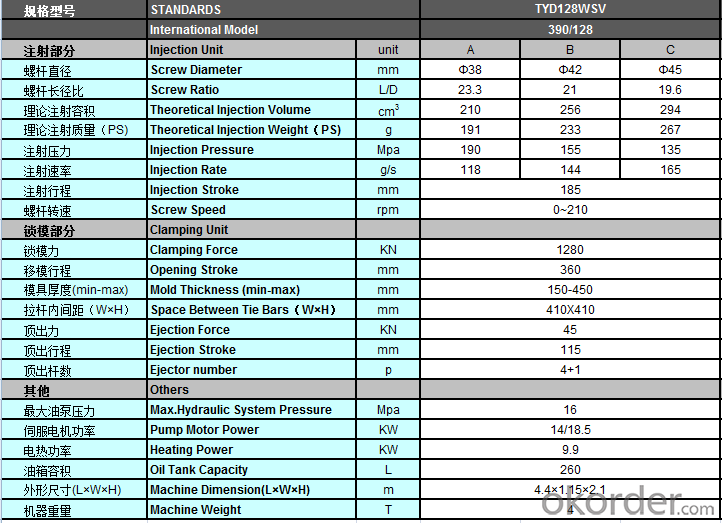

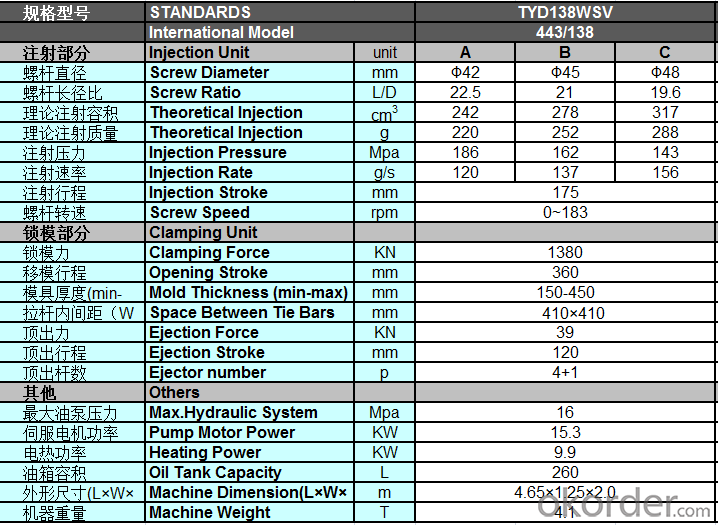

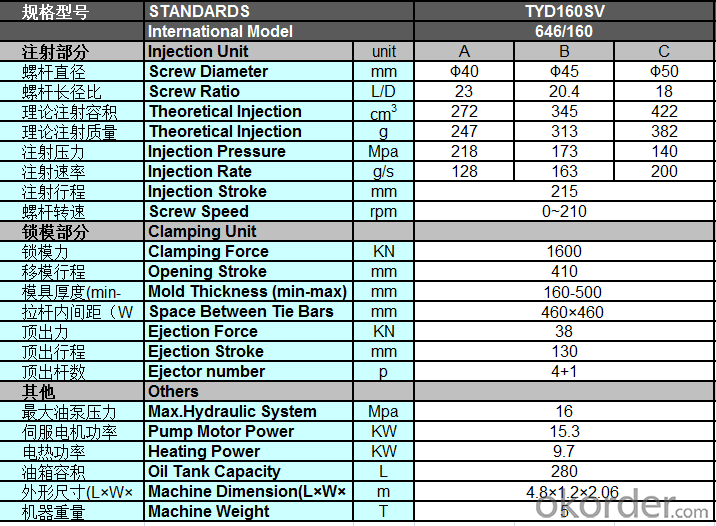

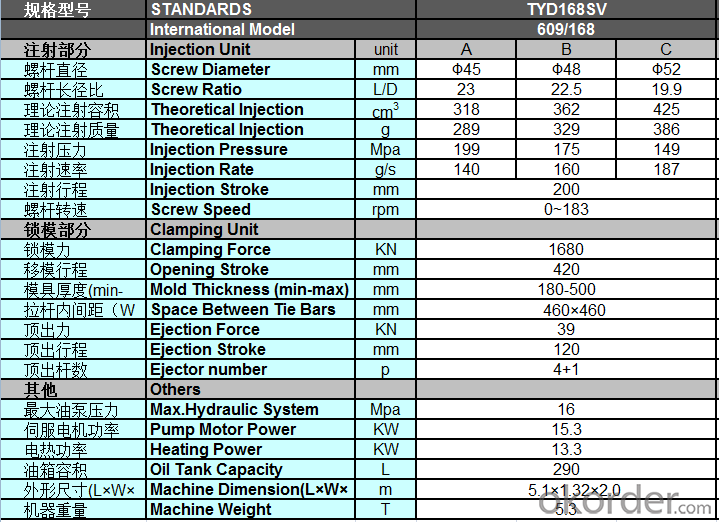

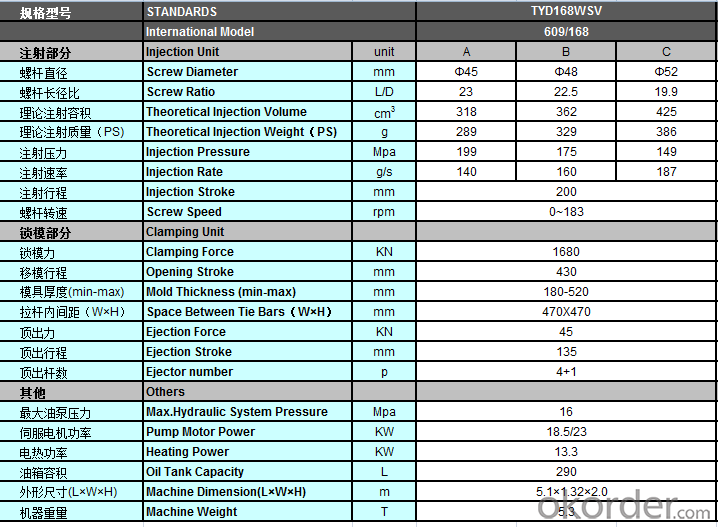

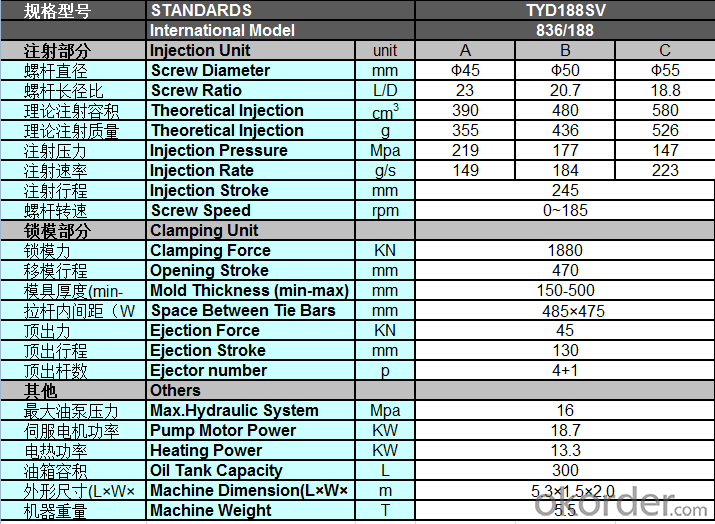

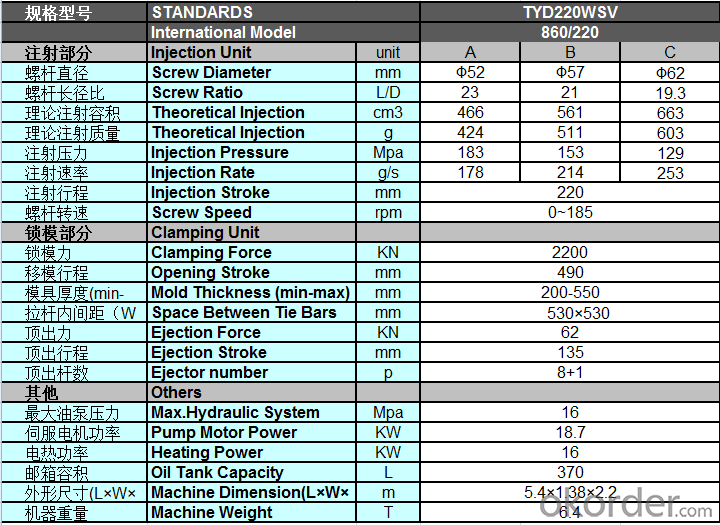

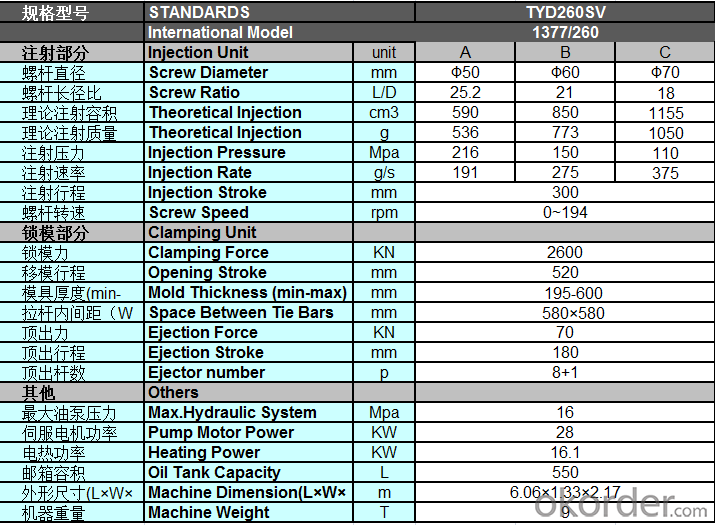

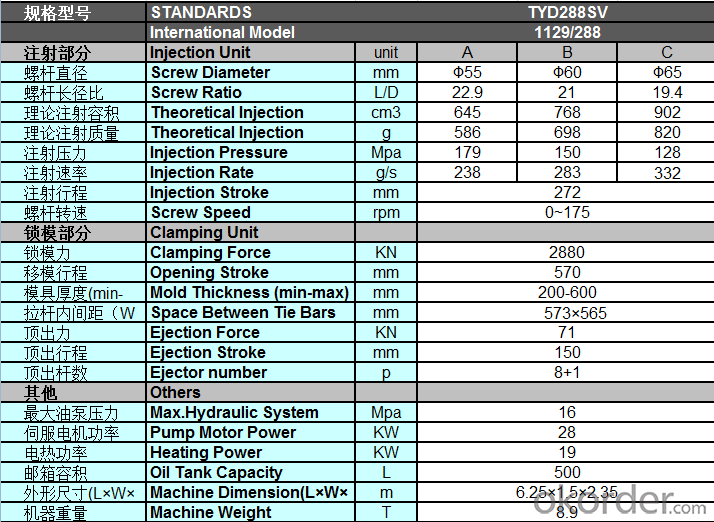

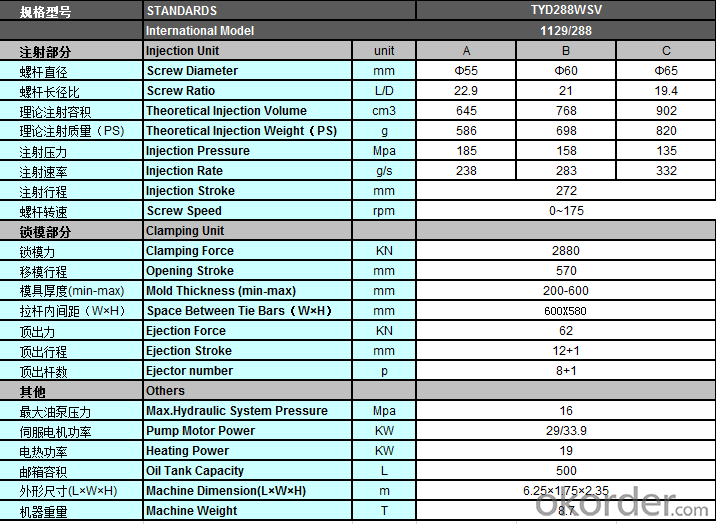

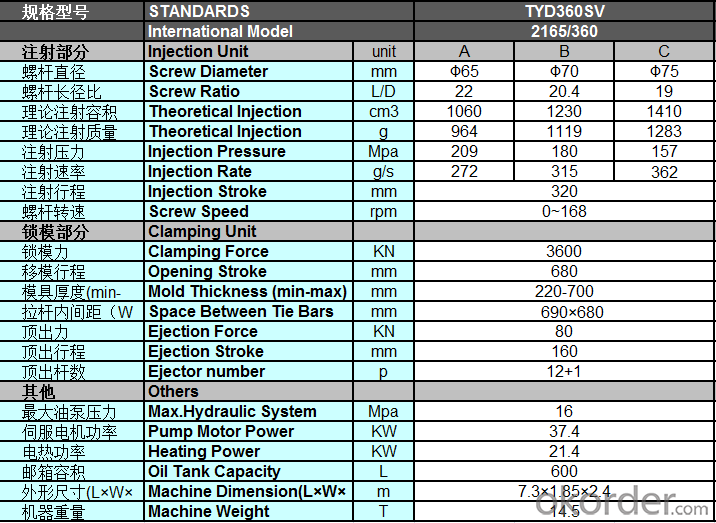

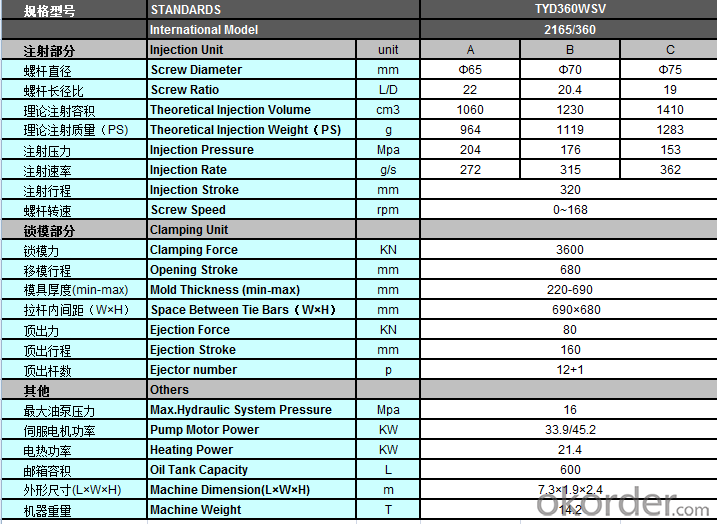

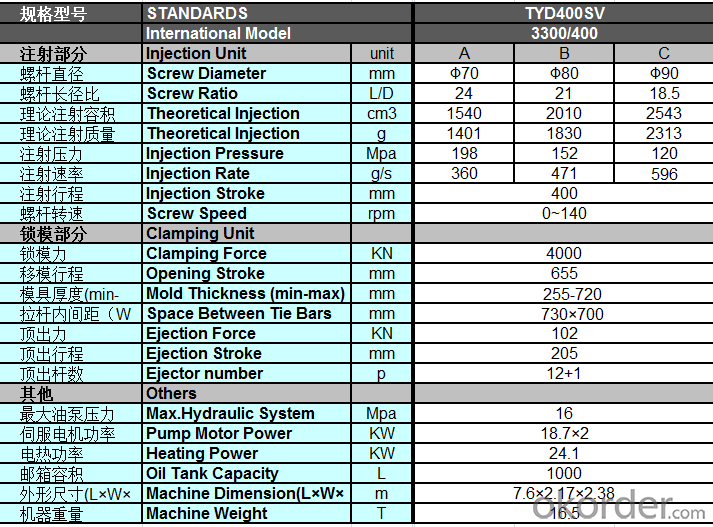

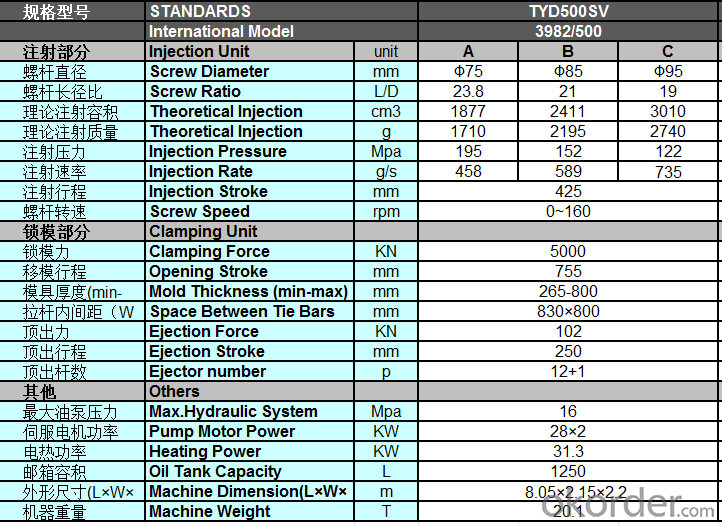

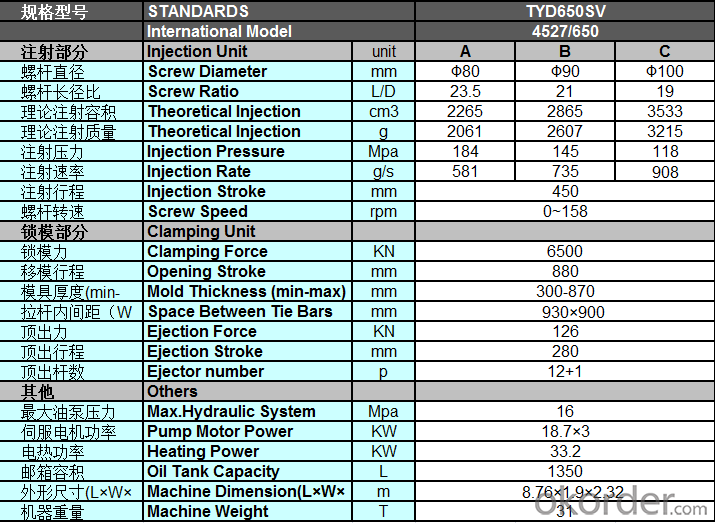

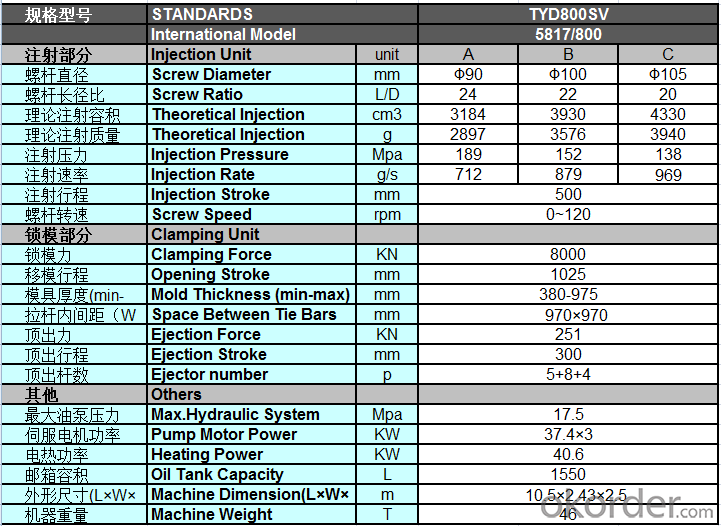

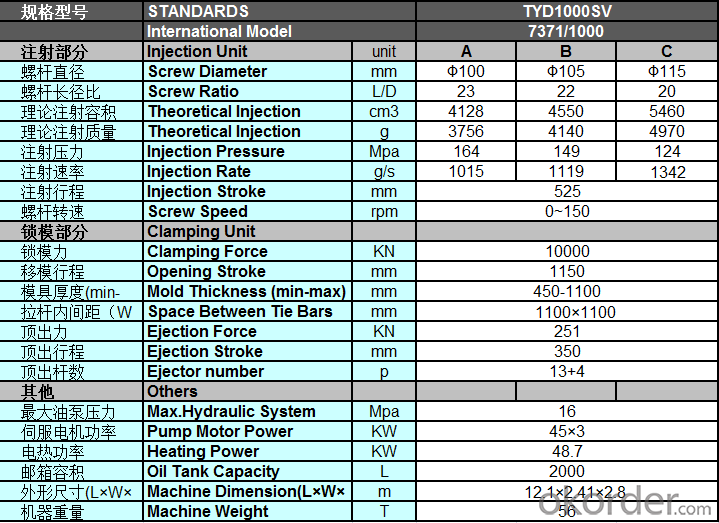

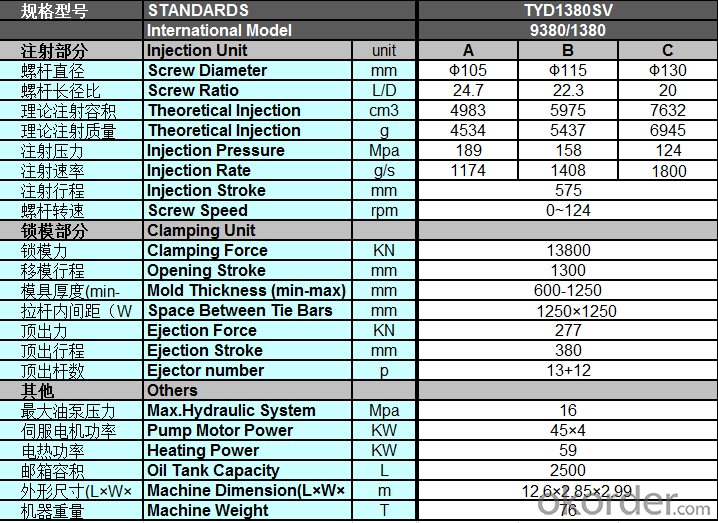

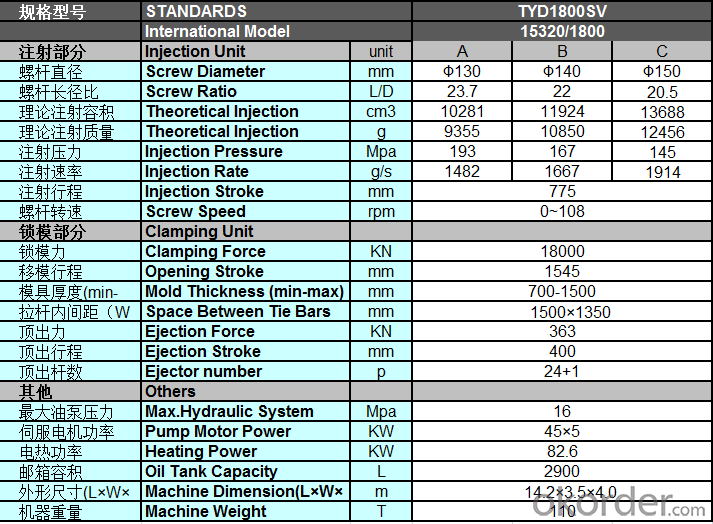

our other machine for your reference

our technical advantage

our packing:

Fine package on pallet. In case of the size and weight requirment, it will be loaded in seperated containers.

Our Services

1. Our manufactory team will help you to choose the TYD machines to match your production demand

2. We apply the OEM service to meet your production requirment

3. Our after-sale service will help you to maintain the machine in proper condition

Company Information

our factory is one of the professional plastic injection molding machinery manufactury in China

The characteristics of the machines are high efficiency and energy saving, the spec are from 50 grams to 20000 grams.

We have 100 sales and service facilities were founded in China and overseas market.

Up to now, our products have sold in Brazil, Pakistan, Russia and other places.

We have passed the ISO 9001:2008 and CE certification.

The main parts of the machine come from Germany, Italy, Japan, Taiwan and other countries.

FAQ

Q. How to choose the TYD injection molding machine?

A. It based on the mold size and mold stroke according to products weight and dimension, wall thickness, properly clamping force and combined with the injection pressure. Our work team will help you to make the good choice if you can apply the products spec.

Q. Do you OEM?

A. Yes, our OEM team would like to work with you.

Q. where is your factory location?

A. we are located in Zhoushan seacost City which is near the Shanghai and Ningbo city. your are welcome to visit our factory.

- Q:Relative to the size of the installation mold, it can also be said to be the internal column or guide column of the injection molding machine. How can this part be translated in English?

- Tie Bars--- pull rod (Ge Linzhu)Clearamce Between Tie Bars is the column spacing is between the Green column, you said the distance, Green column spacing also restricted the installation of the width of the mold, the mold width must be less than the Green column spacing can be put under the lock on shot out!

- Q:How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

- Q:How to calculate the capacity of mold injection molding?

- For example, the first mock exam two points mold cycle for 15 seconds, then 12 hours of production capacity is 60 seconds /15 seconds = 4 mode 4X60=240 per minute per hour 240X12 hour = 2640

- Q:What's the difference between high-speed injection molding machine and ordinary injection molding machine?

- High speed injection molding machine is full motor, ordinary injection molding machine is hydraulic injection molding machine, and hydraulic injection molding machine relative running speed is slower. At present, the full electric injection molding machine uses servo motors to realize the die opening and closing, ejector ejection, raw material injection and storage. And so on, the operation speed is quick and precise, which greatly improves or improves the production environment and production efficiency. But now, servo electric injection molding machine only clamping force of less than 850 tons of machinery.

- Q:How to calculate the clamping force of injection molding machine according to the product

- Clamping force x09F>=k*P*AF= actual clamping force (KN) x091KG = 9.8NP = cavity mean pressure (Mpa) x091MPa = 9.8KGThe projected area (cubic centimeter) of the A= product on the parting surface x09K = safety factor, usually take 1.1-1.6.x09Injection pressure, x09, injection pressure, =1.5* internal pressureGrade x09 internal mold pressure (kg/cm2)Precision products x09550-700Common product x09350-500Liepin x09250-300

- Q:press feeding button feeding, injection machine has been feeding, storage position to still can not stop why, 15With electronic ruler control, is there an electronic ruler problem, how to judge?

- How do you determine that the feed has reached the end of the storage? Whether from the display page screw actual position to the target location is to determine if, please check whether the charging valve is electrified, if not, then the charging valve spool is most likely, if the electricity program is abnormal.If you have any questions, please cross examine and wish you good luck!

- Q:What is the gear adjustment and chain adjustment of the injection molding machine?

- It is the die adjusting mechanism on the tail plate of the injection molding machine. The gear adjusting die is to drive a big gear with a regulating motor, and then the big gear drives the four small gears on the forest column to realize the adjustment and advance of the die. The chain adjustment is to adjust a motor to drive a chain, and then drive a few small gear.

- Q:Pick up a living requirements for luminaires for PVC, never used the material that this material is not good to ask you to the point of transparency is not a lamp, because it will shine requirement.

- Lamps are also translucent, ah, clear requirementsAttention should be paid to plasticization, fluidity and mixing

- Q:The temperature of the injection molding machine: 1 220.2 210.3 200.4 190.5 175 period, when heated, everything is normal, but when the temperature reaches the set value of the motor work, work to about 15~20 minutes, 3 and 4 of the temperature began to rise slowly to 213~220 (lead injection unstable), other Dan normal. Then the motor is switched off, stop, about 15 minutes later, the 3 and 4 section temperature began to slowly fall to the set value, please master: what is the reason? How to solve?

- Hello:You can lower the feed rate a little, and there is a big wear on the material and the cylinder.

- Q:How does the injection machine exhaust?

- On the system pressure plate there is a relief valve, the valve head at the top of the six angle bolts loose on it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

88T plastic injection molding machine TYD88SV plastic making machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords