High-end Triangular Form Traveller with Big Operational Space

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

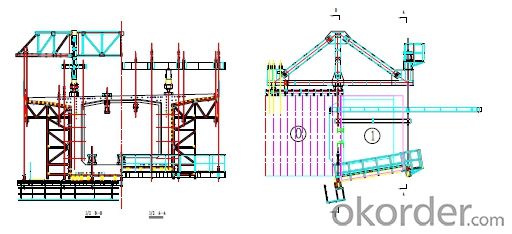

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q:I would like to ask: how to choose the kind of hanging basket? Do their own basket design and production for 2 years, but do is diamond, triangle hanging basket and diamond hanging basket, etc.

- Personal feeling diamond good point, because used a few diamond. The triangle is also seen, mainly to see how the design, such as the design of track running system as long as easy to use is good

- Q:Are there any hanging baskets on both sides of the hanging beam 0

- First, the height of the test results. In line with the requirements do not pre pressure, followed by hanging basket construction 0# block is the most important, pre pressure pouring.

- Q:What should be paid attention to in the construction of cast in place box girder of long span bridge hanging basket

- Main cause:1) no sprinkler health;2) the thermal insulation performance of the template is not good, the temperature difference between inside and outside is too large.

- Q:Hanging basket assembly quality control point

- The hanging basket according to the different structures and stress characteristics, divided into parallel truss basket bowstring, hanging basket, triangle hanging basket and basket, mainly in the following triangle hanging basket as an example.

- Q:A set of hanging basket refers to the symmetry of the left and right two hanging basket or a single hanging basket?

- One set is the left half and the right half of a zero block. To the left and right sides of the two sides of the push. Refer to two!

- Q:Construction technology of bridge hanging basket

- A, pillow and track installation;B, assembled hanging basket main frame;C, installing front cross member and front sling;D, the crane will be used to bridge the bottom of the bottom of the platform to lift the platform, and with the front sling, and then install the rear sling;

- Q:I have a passion for travel, but being a single woman always have problem of companion. Would like to meet other female friends who face same problem. can we come together and form a group? so that we can arrange weekend trips and big holidays also.

- I also find myself in same situation ..Please share your contact details

- Q:What is the meaning of hanging basket in construction

- Refers to the outdoor decoration of the basket.

- Q:After the completion of prestressed tension grouting on the basket can move forward

- Therefore, it is necessary to strictly control the grouting process. Do not allow the prestressed tension after the completion of the grouting on the basket forward. In reality no grouting on the hanging basket forward without accident, mainly due to the design is conservative, safety factor and other factors, to ensure the normal operation of the structure, however, once appear quality accident, it will investigate the problems existing in the construction.

- Q:What is the meaning of the bridge basket and bridge system

- The construction of the bridge hanging basket is mainly used for continuous beam or continuous rigid frame bridge

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-end Triangular Form Traveller with Big Operational Space

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords