Low Gravity Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

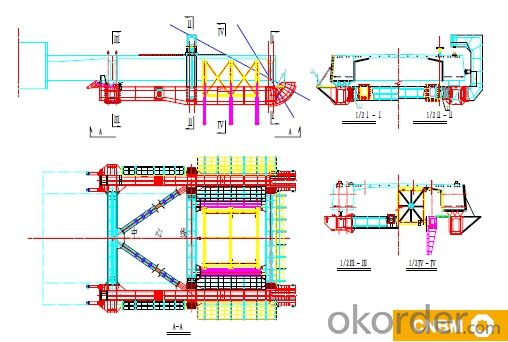

STAYED-CABLE CANTILEVER TRAVELLER

Stayed-cable cantilever traveller is applicable to large-scale stay-cable

cantilever casting bridge with wide bridge deck, heavy and long segment. Most of

the componants concentrates on bottom frame and walking system. It has no main

frame, at the same time, the lift is done by the stay-cable of the bridge. Comparing

with other types, the sigle weight of stayed-cable cantilever traveller is heavier.

●Low gravity of front trancerse beam

●Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

●Safe & easy operation, easy fixing, and safty during walking

●Big operational space under the main frame, and easy installation and removal

- Q:The construction of the hanging basket of the bridge needs to be pre - pressed in each suspension section

- Pull anchor in has Zhang and pier beam into the overall mobile hanging basket. Lashing steel, vertical formwork, pouring concrete, the application of prestress are carried out on it

- Q:Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- Hanging basket when walking, hanging basket as far as possible to do the same time, the difference between the asymmetric distance between the hanging basket is 5cm;One must be responsible for observing the synchronization of walking, the two person is responsible for observing the operation of the walking anchor beam, the two is responsible for observing the operation of the outer die frame bearing;

- Q:The post tensioned prestressed anchorage of suspension bridge can be reused?

- After tensioning is fixed in the beam, can not be reused

- Q:Management measures of hanging basket

- 12.3. fence. In the hanging basket around the set of sealed guardrail, to prevent high-altitude operation, object tools fall wounding.12.4. body tie. The construction of the box beam is placed on the river, and the height is 8. 15 meters, in case of safety requirements for the construction of high-level personnel, tied to the waist belt.12.5, avoid the wind. When the wind up to 7 or more, the hanging basket construction must stop operation, 012.6. lamp. Due to the duration of the project is tight, almost two days and nights of continuous bridge shift work, night construction site must be equipped with adequate lighting to ensure the safety of construction personnel.

- Q:What is the reference standard for hanging basket preloading

- For example, the bridge is a linear change in the loading process, the difference between the maximum and the minimum is only 2 mm. The average deflection is 12 mm. It provides a reliable basis for setting the elevation of the vertical die by preloading

- Q:Cantilever pouring construction should pay attention to what

- The main equipment of the cantilever method is a pair of walking hanging basket, pull anchor in Zhang and pier has connected mobile beam on the whole hanging basket, lashing reinforcement, formwork, pouring concrete, prestress are carried out on the. After the completion of the construction of this section, the hanging basket symmetrical move forward a section, the next pair of beam section construction, in advance, until the cantilever beam section pouring completed.

- Q:How is the prestressed steel bar in the hanging basket method? Is the length of each section of the tension of the prestressing tendons, or tensioned T - shaped steel beam length of prestressed tendons?

- Repeat the above process, so that the cycle of propulsion, until all of the complete beam segment. Specific recommendations for the cast-in-place prestressed box girder construction materials.

- Q:The difference between cast-in-place and hanging basket construction? Why should the construction of hanging basket 0123... Block? The cast-in-place bracket is also divided into pouring and hanging basket so what is the difference between (except for economic differences)

- The difference is that the stent can be poured into the entire collapse of the pouring basket must be divided into sections

- Q:How to define the construction stage of continuous beam bridge hanging basket construction

- Beam with three or more than three supports. Continuous beam with intermediate support

- Q:What's the meaning of the main truss in the basket?

- H ngli ng trussThe [brace girder] is composed of a plurality of slats of the web and the two sides of the connection of the girder

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Gravity Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords