Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

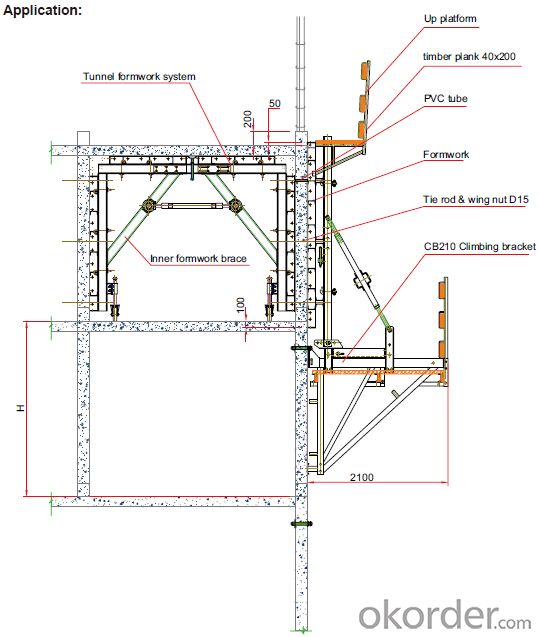

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q:Who can give me detailed tunnel construction process

- Tunnel construction process, the first branch is a temporary payment, two lining is a permanent support.1, the hole before the edge, the construction of the slope (including drainage, electricity, etc.);2, the construction of large pipe shed3, measurement positioning line;4, drilling, blasting;5, slag, playing anchor, steel, injection (including the initial spray and spray)6, ahead of the anchor (after the pipe section)7, measuring the line;

- Q:Loess tunnel construction quality control points

- 3) arch filled with rubble concrete should meet the requirements of the relevant regulations.4) concrete or rubble concrete arch above the back should reach the design strength of concrete arch in the back 70% after construction.

- Q:How to put the positioning point is based on what is mainly based on my novice, do not

- The trolley positioning, the first to the two lining trolley running mileage, and positioning, positioning process will have been completed two off the top two tight lining lining, free end positioning first center point positioning control of elevation and with a plumb line (top surface elevation is equal to the length of the plumb line + if the mileage of two the center point of elevation can be lining),

- Q:When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Electric heating plate can be used for bonding or cold bonding (rubber water seal) or welding (plastic water stop) method, such as user connections are difficult, I can send technical personnel on-site guidance.

- Q:There are no recycling tunnel templates

- Tunnel template, as far as I understand, is the tunnel two lining template

- Q:How the tunnel template is calculated

- The construction specification requires that the main hole should adopt the full section lining formwork trolley, and the other cars can be connected, the man and the equipment can be assembled.At present, the construction of the tunnel in our country basically uses the steel formwork trolley, many provinces and cities have set the minimum thickness of the template.

- Q:1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- The pupil is 5 times as fast as the increases, which makes the dark adaptation time to defend much longer. Cone cells can produce or reduce pigment in 10 ~ 12min, and the rod cells are almost 60min need to produce all of the pigment, which makes it very difficult for people to adapt to a very dark environment. How long does it take, depending on the extent of illumination.

- Q:When the two lining of the tunnel is used as the lining concrete of the two, how to lay the trolley? Please kindly explain steps.

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q:What are the reasons for the two lining concrete lining of the tunnel?

- (4) improper concrete mix, segregation, depending on the template part of the lack of slurry or template serious leakage;(5) no watering wood template wet, water bonding or early form removal, Chaimo missing edge off angle, resulting in reinforcement.

- Q:12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- If the reinforcement in advance or tied to the design of no reinforcement, the normal situation down the car, plus the plug plate, pouring concrete

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords