Form Traveler

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Rhombic Traveler

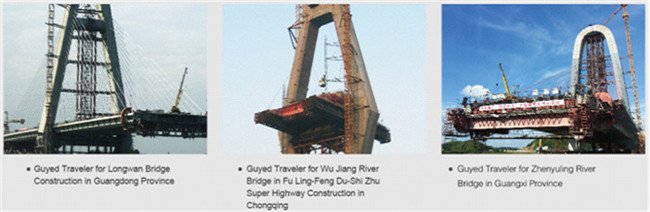

2.Guyed Traveler

3.Triangle Traveler

4.Through Supported Traveler

5.Normal Traveler

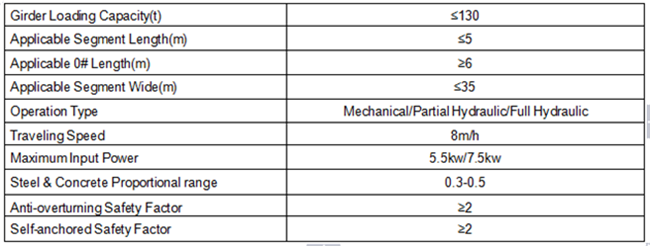

Products Introduction & Application:

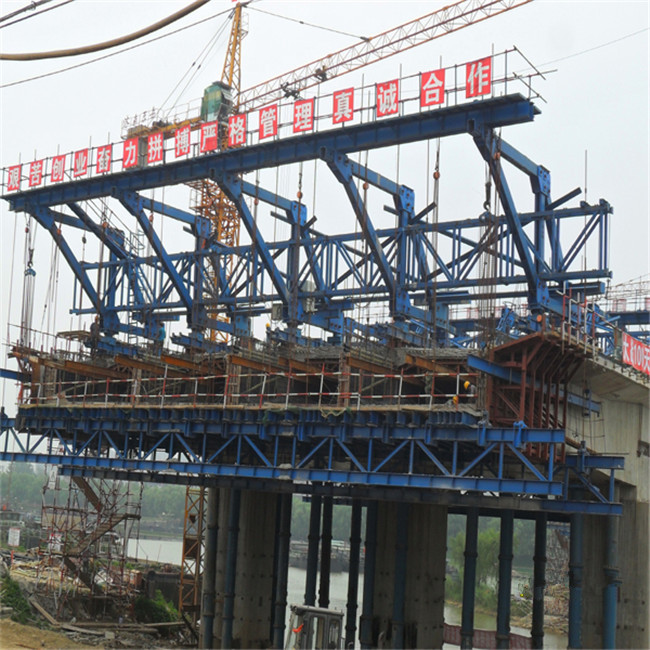

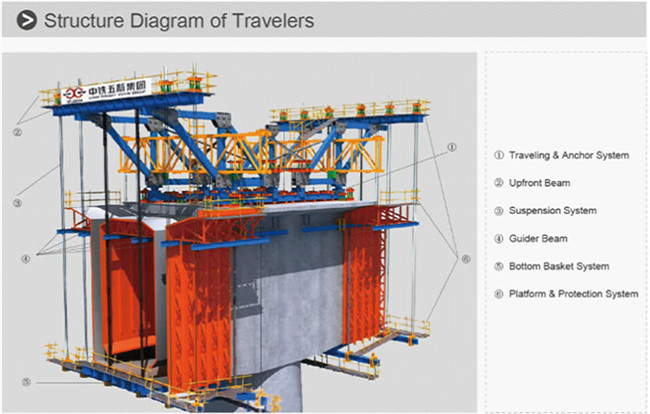

Form traveler is the major equipment used in cantilever construction. The product we developed is consist of main girder system, traveling system, anchor system, bottom basket system, suspension system, platform & protection system, formwork system, hydraulic system(optional) and so on. All the parts are self-contained, interdependent and interrelated, already awarded over 20 authorized patents.

In order to improve universality and utilization, reduce purchasing cost, and enhance security & reliability, we provide the series service of “designing, detecting, renting and constructing form traveler service as well as technical assistance & training.” Today 800 T-structure form travelers can be provided for renting service.

Projects:

- Q:The construction of the hanging basket of the bridge needs to be pre - pressed in each suspension section

- Pull anchor in has Zhang and pier beam into the overall mobile hanging basket. Lashing steel, vertical formwork, pouring concrete, the application of prestress are carried out on it

- Q:Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- The hanging basket in the process of walking, the two should be a walking anchor beam as a whole, to prevent the process of walking anchor beam deviation affect the normal walking, if found walking anchor beam walking by right, should immediately stop walking, the first of its position is adjusted during walking, should additional insurance is hard on walking anchor, anchor in order to adjust the position of the beam;After hanging blue in place, should immediately after the anchor, the box and the top of the box sling anchor, it is strictly prohibited to use internal and external guide beam frame for box beam concrete construction.

- Q:What is the function of the rain - water hanging basket device in the rainwater collection system

- Therefore, the initial need for the initial filtration of rain, rain interception hanging basket device played a role in the initial filtration

- Q:Is hanging basket equipment special equipment? Need to record it?

- The hanging basket equipment belongs to the special equipment.

- Q:Hanging basket construction can bind steel

- At the intersection of steel, the application of 0.7~2.0 mm wire, according to figure 8 staggered or cruciform manner by butting, butting

- Q:Hanging basket assembly quality control point

- The composition of the basketHanging basket bearing system, bottom formwork system, side formwork system (inside and outside), walking system, rear anchorage system. A hanging basket is made up of two triangles, each of which bears the weight of the beam. Taking into account the processing capacity of the construction site, the main beam, the sliding beam, the upper beam and so did not use a reasonable truss structure, and the use of steel structure.

- Q:How to evaluate the construction scheme of bridge hanging basket

- 3 your monitoring measurement scheme is feasible, whether the layout is reasonable4 your basket installation scheme is feasible

- Q:Summary of hanging basket construction:

- Pay attention to the influence of asymmetric force and wind force. The development of cable-stayed bridge in the direction of simplifying and reducing the construction machinery and equipment, strengthening construction control and management. Prior to the construction of the construction to do a detailed calculation, construction to strengthen the measurement analysis to adjust the construction.

- Q:Master, according to the whole process of analysis of the accounting process...... Did not do it, the specific process of each labor subcontracting costs are uncertain, give a train of thoughtThe key is the process unit price analysis process, not the comprehensive subcontracting guidance price. To help with micro letter envelopes......

- Or do you need to calculate the price of labor subcontracting, I do not engage in the contract, I just say to do this industry to understand these things.

- Q:Hanging basket construction contract unit price

- Give you a reference price:Project unit priceCantilever concrete m3 535Cantilever beam reinforcement t 580Steel strand blanking, install t 500

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Form Traveler

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords