Easy Operation and Safety Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

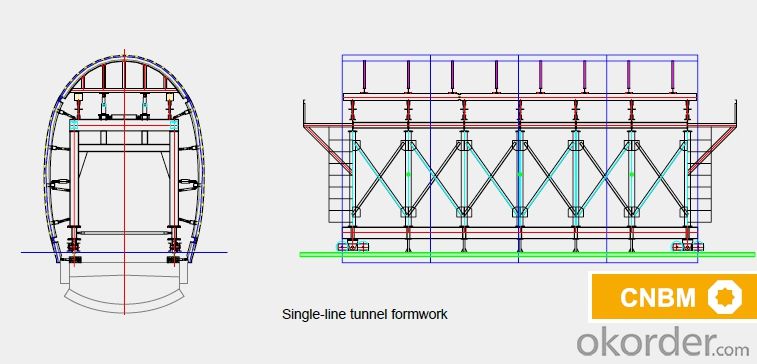

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q:The periphery of the tunnel outline has been sealed with steel seal, and can be used as the external formwork when the concrete is poured. The 3 parts of the tunnel are divided into floor, side wall and roof. When pouring, the concrete can only be pumped in the tunnel, the outside of the tunnel is the Pearl River, and the construction can not be carried out outside the tunnel. The roof pouring, only from the bottom to the pump. Question: 1, the roof concrete pouring, how to discharge the air? How to tamper? 2, the tunnel width of 23 meters, you need to do the construction of the seam or after pouring it? Time is pressing, please reply as soon as possible. Good addition score. Thank you。 If you can't see the picture, click this link:

- Concrete construction technology of tunnel roof:Due to the main roof, the floor of a large amount of concrete pouring, consider the construction period and other factors, the site is equipped with 2 sets of automotive pump or HBT60 pump and 300m Phi pipe and a variety of accessories.

- Q:What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- The first project of concrete lining of this section as I bid the tunnel project, on the next two plays a role model leading lining construction, so the various factors must be considered in detail, before the construction plan, reasonable arrangement, strict control of construction process, construction timely summary, finally reached the first the United States, the project entity information is true and complete, the project finished good target

- Q:How to put the positioning point is based on what is mainly based on my novice, do not

- The trolley positioning, the first to the two lining trolley running mileage, and positioning, positioning process will have been completed two off the top two tight lining lining, free end positioning first center point positioning control of elevation and with a plumb line (top surface elevation is equal to the length of the plumb line + if the mileage of two the center point of elevation can be lining),

- Q:Tunnel construction procedure A cycle of steps

- The construction and tunnel portalWith the support from top to bottom layered excavation hole slopes, and Myeong Dong, and permanent and temporary outside waterproof and drainage should be first, make the surface smooth water, avoid surface water erosion on slope. Is necessary to take artificial slope repair, prevent overbreak, reduce disturbance to the adjacent area; excavation slope will be used in the design of the door, reducing exposure to rock weathering, support to follow, within the jurisdiction for high slopes, if not timely, can not guarantee the safety, and many of the human condition waste,The lining must check and recheck side wall foundation Myeongdong geologic condition and the bearing capacity of the foundation, to meet the design requirements, measurement lofting, frame formwork support, assembling reinforcement, inside and outside the template, the first wall arch integral casting lining concrete, mixing pump into the mold, insert type vibrator with attached type vibrator tamping compaction device.For the construction of portal portal with cut bamboo, also for cutting bamboo cut, plane mounted wooden formwork according to the slope, the slope angle and side end die die fixed into a whole.The waterproof layer and backfillingAfter the completion of open cut tunnel lining strength up to 50% can be removed outside the mold, with a waterproof layer, each layer of backfill should be symmetrical on both sides of the height difference is not greater than 30cm, not more than 50cm, after re stratified backfill to the vault, filled to the completion of a good surface aquifuge.

- Q:When the two lining of the tunnel is used as the lining concrete of the two, how to lay the trolley? Please kindly explain steps.

- The first measurement group with total station will be five points (template center, 2 large side mode along the point, 2 small side mode along the projection point) in lofting invert, with nails into the inverted arch concrete as a symbol, and note the nail surface elevation. The trolley positioning, the first to the two lining trolley running mileage, and positioning, positioning process will have been completed two off the top two tight lining lining, free end positioning first center point positioning control of elevation and with a plumb line (top surface elevation is equal to the length of the plumb line + if the mileage of two the center point of elevation can be lining)

- Q:Demolition of tunnel bearing formwork for several days

- The average temperature of 20 degrees, can be removed for 28 days. High temperature removal time is short, low temperature stripping time longer.

- Q:How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q:What are the steps? If you build a template, how to fill in the concrete. The tunnel is to dig all the generalist pouring, or digging into the side. Simply say. Better picture. In addition, we have seen a video, the shield machine to dig up the tunnel after the installation of a number of prefabricated panels, but these prefabricated plate is curved. Do not have to fill in a semicircle tunnel?

- Two lining trolley consists of two parts, one is the erection and welding of steel trolley, and the other is pouring trolley.

- Q:The arch and the arch of the tunnel

- This part of the tunnel lining is generally the first pouring, pouring formwork trolley can be placed on the inverted arch concrete and support, to the construction of the tunnel arch wall concrete.

- Q:In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Tunnel two lining concrete pouring mould! Template trolley!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Easy Operation and Safety Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords