GPS Hot Water Circulation Pump, Solar Pressure Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

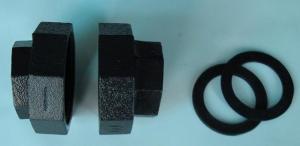

circulator pump, wet rotor type, 304S.S.

no noise <45dB(A), no leakage, environment friendly, easy installation

Domestic speed control (3-speed) Circulation pump

This circulation pump especially designed for heating system and used to supply water

and add pressure for mansions of city,villa of subarb,house,to match with industrial equipment,

to supply water in cycle for cooling air-condition,boiler and solar energy,suppy hot andwater and keep warm cycle.

Construction Material

Motor wire:copper

Motor shell: aluminium

Rotor can: stainless steel 304

Impeller: PP

Pump body: cast iron

Shaft: ceramic/S,S

Bear: ceramic/graphite

Technical Data

Liquid temperature range: -10 - 110°C

Pipe size: G1.5", DN25mm

Port to port length: 180mm

Max. operating pressure: 10bar

Pressure stage, pipe connection: PN10

Electrical Data

Input power(speed 1):46W

Input power(speed 2):67W

Max input power.: 100W

Mains frequency: 50/60Hz

Rated voltage: 110/220V

Max. current: 0.4A

Capacitor size: 3uf

Max flow:65l/min

Max head:6m

- Q:How long should it take a mechanic to replace a water pump on a 96 dodge intrepid ES with a 3.5L engine? I was given a estimate of 6 hours does it really take that long? at 100.00 a hour I'm not sure my car is worth fixing

- YES! It's driven by the timing belt so make sure they replace that too! edit: everything bill b said is true.....but he's thinking of the 2.7 motor. not the 3.5. Thank you. Your welcome. The labor rate in my shop is $95.00 an hour. Most all basic jobs are rated into a labor time data log by auto manufactuers and used world wide! These labor times stand up in a court of law!!! If it calls for 6.0 hours of labor, and you know I charge $95 an hour, that's $570 plus parts. Some shops charge less per hour and use cheap parts and leave bolts out and your constantly having problems. Some try to charge 8.0 hours for a 6.0 job just to rip you off. Some shops never worked on one and some shops are on there 3rd set of special 3.5 cam holders for doing water pumps and timing belts if you know what I mean!! Always get on the phone and shop around. Call the dealer and ask for the labor time for a particular job if you feel the need to.

- Q:Question for you. I'm looking for a 12v (no AC converter, please) water pump to drive up to 4 water misters. Needs to run off the battery, without an AC converter (already found those). The pump will pull from a water reservoir and provide cooling relief on hot days through the misters. BTW... the pump should be reasonably small, limited to a few pounds...If you have any ideas, please advise.Thanks again,Robert

- Again, I'm going to make you work for this one. Call around to junk yards. See if they have any parts you can use. There's a bunch of Pull Apart places where you can look up online to see if they have any particular part you're looking for. I don't know how much a typical automobile water pump weighs, but I don't imagine it would be too big. Ask around. If you know any mechanics, or just people who work on cars as a hobby, they may know. Sorry I'm not much help in the automotive department. I can put gas in it, start it, change my oil, and change a tire. But as far as the rest goes, I don't know too much.

- Q:We just replaced the motor on our water pump that burnt out but we are still getting no water pressure. My father in law did a lot of test stuff on it he thinks it's the foot valve. Well I've been trying to call every where get quotes but NOT 1 of the places I called is answering their phone for some reason. So how much dose it usually run to have someone come fix your foot valve so I have an idea to tell my husband?

- If you want to purchase a foot valve I would suggest you purchase a brass one with a stainless steel screen. where I live that peticular one would cost approximatly $20.00 Also you would need a brass male adapter. Approximately $8.00 and gear clamps All Stainless steel X2 $1.50ea One question: is there water in the pump body? if not then you either have a leak either in the water line leading to the foot valve or the footvalve leakes itself. if there are other questions e-mail Licensed pump installer. good luck. If father inlaw is comfortable doing tests then should be comfortable changing footvalve. with a little bit of help. is it a drilled well or a dug well?

- Q:I have a 2002 honda civic with 85k miles the dealer says the timing belt should be replaced. But with the water pump timing belt tensioner also have to be replaced???

- It relies upon on the vehicle, in diverse fashions, like maximum mitsubishis, you could desire to take the timing belt off to alter the water pump. So then that is an included operation and there is not any extra suitable value linked with the exertions to do the timing belt, it merely makes it a handy, value saving time to do it. there is not any rule approximately changing water pumps and timing belts at the same time. If that is not an included operation there is not any element to do them on a similar time. The timing belt is physically powerful preventative upkeep yet there is not any might desire to alter the water pump previously that is showing signs and indicators, and there are a brilliant style of them, that that is going to die.

- Q:i have a 97 mercury mountaineer and i recently got the thermostat changed in it. after doing so we noticed that the car was leaking antifreeze. we checked to make sure everything was tight and there was no cracks and my uncle said he thinks its the water pump how can i tell

- since the leak only occurred after thermostat change ? it is reasonable to assume it is leaking around the thermostat housing. check this area first . ( did we fit a new gasket ? etc) water pumps have a small hole on underside that will weep ( leak) when seals are worn and pump needs changing. we can check pump is working by observing coolant flow. with a cold engine remove coolant filler cap.start engine and rev a few times to around 3000-35000 rpm observing ( may need an assistant) coolant flow into expansion chamber ( where you removed filler cap from) you should note coolant flowing across or into the expansion tank. if our pump has failed we would over heat !! check engine cooling when driving.

- Q:the pulley wheel fell off while i was driving and all of the pulleys turn except the two under the water pump pulley. does anyone know if that is supposed to spin by hand or will it only spin when the car is running?

- Your water pump should definately be able to be spun by hand. Generally when a water pump goes, or starts to go, it will leak antifreeze and or you will be able to shake the pulley slightly. Double check and try to spin the water pump again without any belt tension on it. A water pump can go at any time however, if your car has less than like 80,000 miles on it, it's probably fine.

- Q:A direct type pump model with the coupling type, what is the difference?

- The direct type shall be the same shaft of the pump and the motor, and the connecting shaft is a pump and the motor shall be 2 shafts, and shall be connected by a shaft coupling.

- Q:I do pump sales ~ only to enter the line soon ~ often asked how many levels of motor? I can't recognize myself! So ask for advice here

- Look at the speed, see the modelFor example, the actual 1430r/min synchronous speed is 1500 rpm, the speed formula: speed = time (60 seconds) * frequency (50HZ) divided by the number of pole pairs one pole of 2 pole, which can be calculated 3000 83019 1500=2 on pole or 4 pole motor.See model is more straightforward: for example motor model is Y 132 M- 4Y, three-phase asynchronous motor, the three-phase asynchronous motor product name: YR for winding type asynchronous motor; YB explosion-proof induction motor; YQ high starting torque of asynchronous motor. ?132, a high center (mm)M code, frame length4, the number of polesFrom the motor nameplate marked, you can see that the motor is 2, model FW12-2, speed 2840

- Q:Where is the water pump located in a 1995 Toyota tacoma pick up truck. Please be as specific as possible as the the location of the pump. Like what is it undwr or next to...etc

- If you have the v-6 then the water pump is driven by the timing belt and you have to remove the fan belts and the timing cover just to see it . The 4 cylinder the pump is driven by the fan belt that drives the alternator and the fan .

- Q:Multi storey residential buildings also need to set up pressurized water pump room, direct water supply can not be?

- Multi-storey residential building in general can use tap water pipe network pressure water directly, but all regions due to different network differences, in some areas, because of the lower pressure of the municipal pipe network, such as lack of high-rise building 5-6 pressure, can direct water supply cannot meet the demand of domestic water use, then you need the two pressurized water supply. The general water supply equipment needs the construction of pumping stations, and the pump house can be built on the first floor or the ground floor. There are also no water supply equipment, such as pipe pump, frequency conversion water supply equipment, the water supply equipment from outside to see, is a group of stainless steel pipeline, no pumping room. Outdoor box type water supply equipment is also a choice, water supply equipment comes with equipment, can be placed outdoors. Zibo Boshan new Duke water supply equipment

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GPS Hot Water Circulation Pump, Solar Pressure Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords