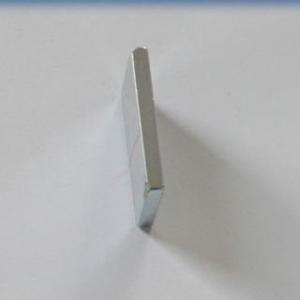

Generator NDFEB Magnet Segment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 100 Tons per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Generator Magnet Segment:Grade in M,H,SH,EH series

Coating:Ni,Cu,Ni,Zn, Sn, Ag,

Work Temperature:as high as 200 Centigrade!

The sintered NdFeB magnet is a high properties permanent magnetic material, which is formed by metals Neodymium, iron, boron and some other rare earth elements.

Because of its best properties, reasonable price, the sintered NdFeB magnet are developed rapidly and found in wide applications such as communication, traffic, instrument, electro-acoustics, motors, magnetic therapy, magnetic machinery, magnetic separation, magnetization technology, etc.

Now our company produces high properties magnetic materials in various grades, such as N35-53, 35-50M, 30-48H, 30-42SH, 28-40UH-, 28-35EH with Br 11~14.9 Kgs and iHC 12~30 Koe.

Per your requirement, the sintered NdFeB magnet can be customized into many shapes, such as triangle/square/rectangle/block, trapezium, round/circle/ring/ball(sphere)/sphere/rod/stick/pot, bar, strip, tile/arc, cube, cylinder, cone, disc/disk, segment, etc or some irregular shapes. Our company can also optimize NdFeB magnet with consideration of its work environment(temperature, force, etc).

The NdFeB magnet surface can be treated and coated in many requested ways, such as coated with Zn,Ni,Sn,Ag,Au,epoxy resin or with Pb element eliminated etc.

- Q:Is any body has any idea about NDT (non destructive test for welding inspection?

- For magnetic materials eg carbon steel, Magnetic Particle Induction (MPI) is normally used - a spray containing magnetic particles is sprayed onto the weld, and a magnet is held close by. The magnetic particles will be pulled into any cracks and they will be visible. For non-magnetic materials eg stainless steel, usually the Dye Penetration (Dye Pen) method is used where a special red dye is sprayed onto the weld which will penetrate any cracks, and make them visible. X-raying of welds - If there are several, or even hundreds of welds, usually a sample is x-rayed (or 'bombed'). It's usually 10% of butt welds are bombed, and if any faults are found then the percentage is increased. Bombing is the best method, but takes far longer, more expensive, and means large areas of plant are inaccessible during the x-ray exposures. It's a matter of course that pipe-welds are normally hydro-tested also. That means the pipe-ends are blanked, the pipes are filled with water, any air is vented off, and the water pressure increased. The test pressure is usually 150% of maximum allowable working pressure for strength testing of welds, but this can vary widely depending on the client's specification Also it depends on the kind of industry you're talking of. An oilrig (where my experience is)would usually do the things I've stated above. For the nuclear industry, or aircraft industry, the specs may be more stringent (for example 100% bomb, every weld gets it). There's also various ultrasonic techniques (UT) that give an indication of how deep the weld is. There's probably more techniques, but these are the main ones by far.

- Q:Why can't capacitors use magnetic materials?

- The method of reducing parasitic inductance of capacitors is to improve manufacturing structures rather than materials.

- Q:And what other types of metals are non magneticIf so any reason why

- It has to due with the quantum mechanics and Pauli exclusionary principle. Electron spin states in ferromagnetic materials are not fully occupied unless there are several atoms lined up such that their magnetic dipoles (think of a little current around the nucleus, which is hihgly oversimplied) all point the same way. Aluminum doesn't have that property. It is diamagnetic though, which means it is at lesat a little magnetic.

- Q:What is Developer Mix?

- In present day laser printers we use mono component toner. The ink or the toner is magnetic material so its sticking to the magnetic roller in the toner module. Earlier days and present day high volume printers do not use magnetic ink. There we use two different materials or dual component development. The toner is carbon particle and non-magnetic. The developer is ferrous material it sticks to the magnetic roller and the carbon powder sticks to the developer due to electrostatic charge. This developer is used only as carrier and never exhausted. This developer and toner mix is called developer mix.

- Q:How do you make a magnetic substance into a magnet?

- HP increase from an exhaust. That always puts a smile on my face. Thanks!

- Q:What is the magnetic power produced in the coils of an 7.5 HP AC motor when it is being run in full speed?The coils in a motor are being magnetized when we supply DC current to it and thus the motor runs.What is the magnetic power produced in the coils in terms of Teslas when the motor is being run in full speed?

- many times a small shop like mikes muffler will have an aftermarket converter he can install for about 200 bucks the pipes are probably stainless he will cut in and weld the converter on

- Q:Why should the magnetic material be electroplated?

- It is an alloy material, after plating, the appearance is better, and then the impact of the magnetic

- Q:At what--if any--temperature does a magnet melt and is a melted magnet still magnetic?

- Probably because it's cold outside.

- Q:whats the difference between a charged plastic rod and tha attraction for a small peice of paper and that of a magnet and how it attracts a small piece of iron?

- 20 pounds is the limit during your entire pregnancy. This is what my OB has told me 3 times. My pregnancy books say it depends on your physical aspects, so it might vary by height weight.

- Q:What are the magnetic materials?

- From the scientific and technological content of ordinary magnetic materials and nano magnetic materials5. iron chromium cobalt, aluminum nickel cobalt, SmCo, NdFeB, ferrite.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Generator NDFEB Magnet Segment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 100 Tons per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords