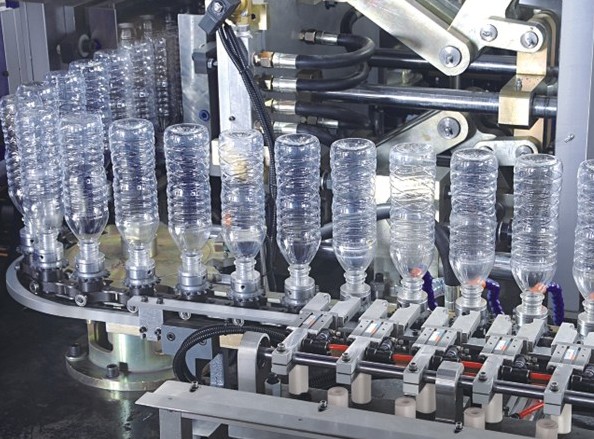

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

blow molding machine

Features:

Automatic perform input and ready bottle output system.

Machine adopt with the overall structure of super-standard anti-vibration design, high-speed operation state of the machine will shake down to a minimum.

Machine adopts modular assembly method, greatly decrease the local amendments due to technological improvements when the machine is on processing.

The structure of machine oven adopt the international most advanced energy-saving technology of infrared radiation heating, temperature control with automatic negative feedback, closed-loop regulation model.

Automation controlling item adopts international high-end computer system, heating, collecting and measuring perform temperature with simulation input and output module.

Man-machine interface displays current production situation, available for on line switching, parameter modification and production accounting, with automatic alarm, automatic fault detection and diagnose.\function.

Description for machine

TYPE | ITEM | UNIT | ZS-F2 | ZS-F3 | ZS-F4 |

CONTAINER | Number of cavity | Cav. | 2 | 3 | 4 |

Theoretical output | Pcs/Hr | 2000 | 3000 | 4000 | |

Max.container volume | L | 2.0 | 2.0 | 2.0 | |

Max.neck diameter | MM | 45 | 45 | 38 | |

Max.container diameter | MM | 110 | 110 | 100 | |

Max.container height | MM | 330 | 330 | 330 | |

ELECTRICAL SYSTEM | Installation power | KW | 27 | 48 | 56 |

Max.heating power | KW | 24 | 42 | 54 | |

Actual power consumption | KW | 15 | 24 | 30 | |

MACHINE | Main machine dimension | M | 3.1x1.7x2.3 | 3.2x1.8x2.3 | 3.6x2.1x2.3 |

Feeding machine dimension | m | 2.1x1.3 x.2.5 | 2.1x1.4 x.2.5 | 2.1x1.4 x.2.5 | |

Main machine weight | KG | 2200 | 2200 | 3000 | |

Feeding machine weight | KG | 250 | 260 | 260 |

Company Information

blow molding machine

ZS factory

ZS sample room

Our Services

1.your inquiry related to our product & price will be replied within 24hours.

2.Well-trained & experienced staff are to answer all your inquires in English of course.

3.OEM&ODM projects are highly welcomed. We have strong R&D team here to help.

4.Your business relationship with us will be confidential to any third party.

5.Good after sale service offered, please get back if you got question.

FAQ

Q: Payment

A: 30% T/T as down pament, 70% by T/T before shopment

Q:Delivery time

A:30 days after down payment

- Q:Does the vertical centrifugal oil filter have any residue in the filtered oil?

- What oil do you filter? The high speed centrifugal oil filter can filter out the slag

- Q:Operating principle and characteristics of electrostatic oil filter

- The impurity particles less than 0.1 M can be effectively removed, and the filtering accuracy is high. After many cycles of filtration, the cleanliness of the oil can be kept at NAS1638:5--8 level without clogging. Suitable for precision hydraulic system with servo system

- Q:What kind of vacuum oil filter belongs to the fixed assets?

- Hydraulic oil filter, vacuum oil filter, coalescence dehydration filter, high precision oil filter, high viscosity oil filter, etc.

- Q:How about the rental fee for vacuum oil filter?

- Of course, buying cheap things that will last two or three years of life can be a waste. As for you, if you really want to rent, only in the vicinity of the local oil filter companies to buy, ask to see how specific people rent, how much money, this is to talk to each other, bargaining.

- Q:What is the advantage of a centrifugal oil filter?

- The centrifugal oil filter is to generate centrifugal force through the high-speed propaganda of the motor, and the oil sludge in the oil is thrown to the inner wall of the oil filter.For mature oil, the oil filter works better and faster.For low temperature, cold oil, the effect is not good.I hope my answer can help you.

- Q:Vacuum dewatering oil filter and coalescence separation dehydration, which dehydration effect is strong?

- The coalescence separation method does not affect the quality of the oil because of its principle. The coalescence of free water in the oil is carried out by a coalescence filter element arranged in the pre assembled dewatering filter to realize the coalescence of free water into a water drop. With gravity, 70% of the water droplets fall to the bottom of the trap, and part of the water droplets move along the flow to the oil outlet. At this point, the separation filter has made a huge difference: it captures 99.9% of the water droplets and allows the oil (or other medium) to pass smoothly. Laboratory data show that the coalescence dehydration can reach alarming data water content less than or equal to 10ppm.

- Q:Difference between low speed and high speed of centrifugal oil filter

- High speed centrifuge is the main filtration principle of centrifugal oil filter of the centrifugal force generated, so as to realize oil-water separation and oil separation

- Q:What is the accuracy of 300*300 oil filter paper for LY-100 plate and frame pressure oil filters?

- The filtering accuracy of filter paper is independent of the filter paper area, and the filter paper has a large area, but it only increases the filtration area and improves the filtration efficiency.

- Q:Why does the oil filter run out of vacuum? How can we solve it?

- The cause of the accident in the oil level is too high) vacuum separator solution) open the equipment town valve, in order to reduce the level of vacuum separator in Chongqing tonre oil company to remind all the new and old customers, if you want to save the trouble, the best is in the purchase of equipment, requires manufacturers, provided with vacuum oil filter automatic bubble elimination device., this device can effectively prevent the vacuum injection, so as to protect the safety of the vacuum pump, prolonging the service life of the vacuum pump, to ensure safe and reliable operation of the vacuum oil filter, and also has the advantages of simple operation, reliable operation, easy maintenance, so that the oil filter efficiency will be higher. The above is the oil filter operation in the common fuel injection phenomenon, troubleshooting methods, hoping to filter oil customers in all industries to bring convenience.

- Q:What cloth is the filter cloth used to filter oil? Where can I buy it?

- On the other hand, the smaller aperture, the more oil filter mesh, the speed will be slow, but the oil filter cleaner.Generally it is necessary to configure the speed of the oil filter and the type of oil filter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches