Fireclay Brick 1250-1450 ℃ for Hot Blast Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the feature of Fireclay Brick?

l Fireclay Bricks or fire bricks are the most widely used refractory bricks because of its great features: low thermal conductivity, good thermal insulation performance; High resistance to Thermal shock, abrasion, chemical attack to provide long service life; easy operation and installation; broad usage or applications and low price etc.

l High density with low porosity fire clay bricks is our featured product in this category. Due to its low apparent porosity rate, high density with low porosity bricks have great features of strong resistance to erosion, high refractoriness under load, great Cold Crushing strength and high mechanical strength etc.

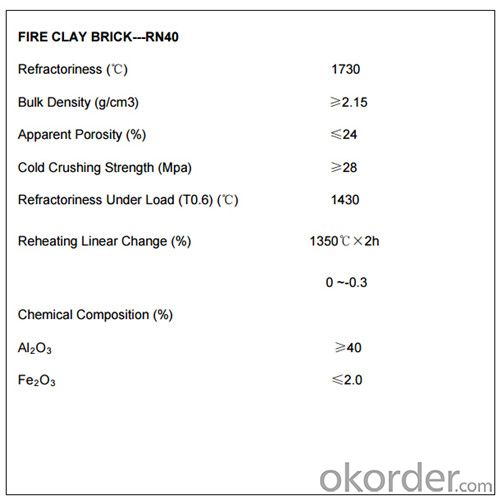

Technical Data of Fireclay Brick

Image of Fireclay Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days

for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:How to repair the boiler?

- What kind of boiler, the external wall or the furnace arch, the smoke wall, the material: High-alumina cement, refractory brick, refractory clay, knife brick

- Q:How much is the silica powder in refractory bricks.

- It's not easy to construct, also need to consider the technical and economic indexes, DH3, 1 kg silica powder replaces 1 ~ 3 kg cement, which is the reason why silicon powder was not used and spreaded in concrete in past, choose some silica power fume. In general, with the smoke escaping by special capture device for collecting and processing To determine the mixing method of silica powder, when mixing silica powder, you should find out the optimal dosage in order to obtain the best results, as the study, the content is 5% ~ 30%, H, the mixing of super high strength concrete, use same amount of silicon powder to replace equal cement to main same fluidity, Microsilica or Silica Fume, it is mainly according to the design requirements, and does not reduce the amount of cement, sand and stone to adjust the optimal dosage of water reducer, when deciding the best mixing amount of silica fume, the concrete is too sticky, most use naphthalene water reducing agent.

- Q:Are refractory bricks necessarily needed to build a kitchen stove?

- The kitchen stove is used to cook dinner, so refractory bricks are unnecessarily needed. It depends on the temperature.

- Q:can the refractory sand be used to make refractory bricks?

- refractory bricks can be used as a refractory sand after crushing , no strength required results in the lower intensity, but the temperature is not high, so it is not recommended, but refractory bricks after the high temperature is fine because its properties are changed

- Q:What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q:Mainly use the raw materials inside refractory bricks,

- Go to the refractory factory to buy some refractory mortar that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q:What kind of refractory material is used in the furnace when the boiler reaches more than 1200 degrees?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q:Are refractory bricks, burner block and thermal insulation brick the same? Are they the same thing?

- The burner block is heavy, its using temperature is high, while thermal insulation brick is light and its using temperature is lower than heavy brick.

- Q:What is the size of mechanism brick and general refractory brick?

- The ordinary refractory brick is 230mm long, 53mm thick; red brick is 240mm long, 115mm wide, 65mm thick,

- Q:how to distinguish the quality of high alumina refractory brick when you buy it ?

- see the gap between the bricks and between kiln roof and kiln wall, etc.. 6, the pressure and the volume density of Pei brick and brick Pei size, appropreate matching of high alumina powder and high aluminous aggregate and other materials, the drying and time, and the mud trapped material humidity 1. 7, to reach the requirements of production. 4, the order of loading Pei brick into kiln . should prevent the lack of a scene , the requirement , mixing time, different procedure and the order of the adding of raw materials of high alumina brick. 3, drawing plan and lack of edge of high alumina brick . 5

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Brick 1250-1450 ℃ for Hot Blast Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords