Courts Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

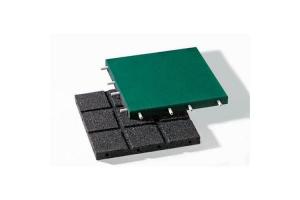

Description of Rubber Flooring Courts Series

Rubber Flooring Courts Series is an extremely durable, tough, non-porous, non-skid rubber mat that can withstand heavy industrial and commercial use. It will resist tearing, cutting, freezing, and reduces noise levels. Ice does not stick to it and it can be permanently laid on wood, metal, tile, and concrete surfaces. This sport mat is made recycled rubber flooring offers the perfect choice for slip resistance, sound absorption, and comfort.

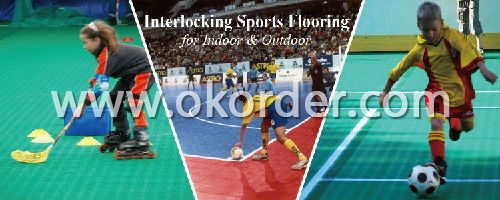

Applications of Rubber Flooring Courts Series

Subdistrict courts, school and college tennis, badminton, basketball courts...

Properties of Rubber Flooring Courts Series

· Prefabricated in factory, uniform thickness.

· Moderate hardness, durable.

· Adapt to all-weathers, anti-UV and hydroxylation.

· Excellent elasticity and air-permeated.

· Be able to glue with different top coatings, such as: PU, Acrylic, Si-PU, saving base material.

Product Dimension of Rubber Flooring Courts Series

Type | thickness | width | length |

Rubber roll,

base mat and material for courts | 2mm | 1.22-1.5m | ≤20m |

3mm | 1.22-1.5m | ≤20m | |

4mm | 1.22-1.5m | ≤20m | |

5mm | 1.22-1.5m | ≤20m | |

6mm-20mm | 1.22-1.5m | ≤20m |

- Q:How to identify the difference between oak flooring and rubber wood flooring?

- Rubber wood is a production plant, rubber latex, rubber tree is the main, sub tropical species. Rubber trees grow into a year after tapping, with a knife in the trunk lateral semicircular incision cut slightly downward, out of juice is the original gum, is the manufacture of rubber materials. The old tree can make furniture with its trunk.Oak belongs to Fagaceae, Quercus, oak on the market can be divided into two categories of red oak and white oak, red oak, white oak is not red but not white, the color is not very obvious, the distinction between the point is to learn the hole in the wood, wood ray difference.

- Q:What are the general specifications of sports rubber flooring

- The total thickness of the 1.6mm-3.2mm (only commercial floor, the floor can be more than 4mm, 5mm, 6mm, etc.). The specifications of the sheet flooring are mainly divided into strip and square.

- Q:The price of rubber flooring is expensive

- (also called with no scratches no scratches or through anti scratch), currently on the market called dance and dance floor or the floor of the stage is divided into three kinds: first have a scratch of several (different PVC content in different prices) and second paragraph two (no scratches high elasticity, the import side) third, also known as scratch through no scratches. Shanghai Shanghai anti scratch dance floor

- Q:Rubber flooring can be used for home decoration

- Yes, but rubber is also divided into many kinds of materials and many kinds of

- Q:The company needs to buy rubber flooring, but the supplier provides the test report is 10 years, is it normal? He said there were 3-5 years of validity, right?

- This is not a fixed term of validity, some standards in the sampling requirements for specific instructions, or by the supply and demand sides consultations

- Q:Rubber floor harmful to the human body

- According to scientists, the plastic floor of the HCL harmful gases released in its 130 degrees above the continuous high temperature environment. Therefore, it is not enough to pose a threat to the human body.

- Q:What's different about the material? Five

- As the name suggests, rubber flooring is made of natural rubber, synthetic rubber and other ingredients made of polymer materials. SBR, high benzene, butadiene rubber is synthetic rubber, oil products. Natural rubber is a rubber tree that is grown from a rubber tree. Rubber flooring is environmentally friendly floor, because all the materials are non-toxic environmentally friendly materials and polymer materials.

- Q:The homogeneous plastic floor and what advantages and disadvantages?

- Small seam and seamless welding - ground material using hot melt welding, forming a seamless connection, to avoid the cracks and more vulnerable to pollution, moisture-proof, dustproof, clean effect. Special color blocks by strict construction and installation, the joints are very small, special varieties of view almost invisible seams in the environment on the effect of higher requirements such as office, or high requirements on the disinfection of the environment such as the hospital operation room is the most ideal choice.

- Q:What's the difference between a wood floor and a rubber floor?

- Wood floor with what we know! Rubber flooring used in hospitals and other large venues

- Q:Now in France to study, accidentally burned the public kitchen rubber flooring, about 30 square centimeters, I would like to ask the need to replace the entire floor glue? Expensive not expensive.

- In France, involving artificial,For example, such as floor tiles, labor costs are very expensive, and time-consuming.This kind of thing, it is best to ask the landlord how to deal with,Perhaps the landlord does not pursue, also may become aggravated landlord is very hard to say,But in any case, it should first communicate with the landlord.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | US$ 50 Million - US$ 100 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Courts Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products