Commercial 3000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

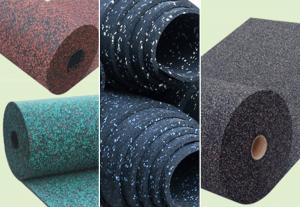

Description of Rubber Flooring Commercial 3000Series

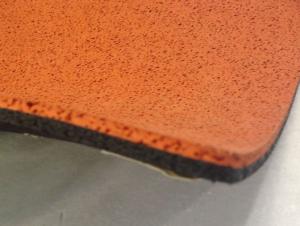

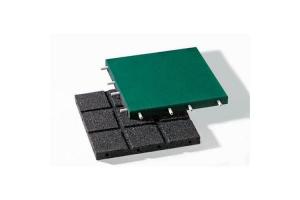

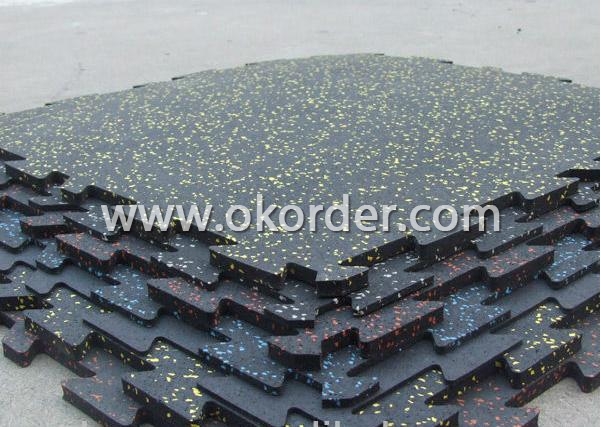

Commercial 3000Series are made of 70% black rubber granules and 30% synthetic EPDM granules. This range of products are combined the Human movement mechanics and characteristics of rubber materials with steady performance and smooth surface flooring made in factory. This kind of flooring maintain the good resilience and offer the wide customers with safe, comfortable and soft while playing, working and living.

Features of Rubber Flooring Commercial 3000Series

Rich colors

Environmental friendly, non-toxic

Recycled, non-pollution

Moderate and adjusted hardness

Excellent resilience, wear well

Soft, anti-slip, anti-fatigue

Convenient installation and easy maintenance

Application of Rubber Flooring Commercial 3000Series

Fitness center, leisure center, club, golf practice court, golf club, ice arena, play field, supermarket, office building, office, meeting room, library, museum, stadium, hospital, school, kindergarten, factory and the fitness flooring in the house.

Parameters of Rubber Flooring Commercial 3000Series

Density (kg/m):1050/1250

Hardness (Shore a):70

Stretch (MPA):2.2

Abrasion resistance:0.0075g(ASTM-D4060-01)

Rebound resistance: 55%

Friction coefficient;trends μs:0.995.trends μk :0.930

Shape deformation:42%

Length (m):10/15/20m ±5cm

Width (m):1m/1.25m ±5mm

Thickness (mm):4-10mm ±0.3mm

- Q:What are the main points of the elastic rubber flooring

- Rubber flooring is made of natural rubber, synthetic rubber and other components of polymer materials made of floor. Natural rubber is a rubber tree that is grown from a rubber tree. SBR, high benzene, butadiene rubber is synthetic rubber, oil products. Rubber floor made of rubber as main raw material, which is divided into homogeneous and heterogeneous relief surface and smooth surface. Homogeneous rubber floor refers to natural rubber or synthetic rubber based, monolayer or multilayer structure of CDs color, composition consistent with a floor; heterogeneous rubber floor floor: refers to is based on natural rubber or synthetic rubber, the structure comprises a wear resistant layer and the other in composition and (or) the design of different compaction layer a compaction layer contains the skeleton layer.

- Q:What is the meaning of self leveling rubber floor

- Self leveling is to solve the problem of horizon, paving the floor of the need for rubber flooring, if there is a small grain of sand on the ground did not clean up, it will make the laying of the floor uneven. In this case, often make the floor is not wear-resistant, uneven aesthetic enough, look ugly.

- Q:Linen floor? Rubber floor? Their adaptability? What is the linen floorWhat is the glue of sticky plastic floor

- [PVC floor and rubber floor difference]Color difference: rubber floor coloring is difficult, because the rubber suction color is very strong, so most of the rubber floor color is single; and very much PVC floor color, can be any combination, can give designers more options.

- Q:What is the meaning of waterproof rubber floor E3

- Waterproof waterproof board as strong board significance concept focuses on the board characteristics in non sudden fear of water water bubble has meaning wood drum deformation the strict sense of the enemy water board double sealing wax film through groove plate joining technology content in wood (0.6 mm penetrate into the substrate substrate with wax lick hunting aldehyde a) seal prevents water from entering the substrate Duffy waterproof effect

- Q:The difference between the rubber floor and the PVC floor is the difference between the plastic floor and the PVC floor

- Different ingredients and production processes: rubber flooring is divided into homogeneous and heterogeneous. Homogeneous rubber flooring is a natural rubber or synthetic rubber based, PVC floor and plastic floor is a class, but the name is different, the main component is PVC resin and natural stone powder processing

- Q:What are their strengths and weaknesses?

- Plastic floor (PVC floor). Operation room on environmental health requirements are relatively high, and now the hospital is required to use plastic floor. From the cost, the price of plastic floor is relatively cheap.

- Q:Rubber floor harmful to the human body

- According to scientists, the plastic floor of the HCL harmful gases released in its 130 degrees above the continuous high temperature environment. Therefore, it is not enough to pose a threat to the human body.

- Q:The difference between rubber floor and rubber floor Rubber floor pressure

- You call the pressure refers to whether there are traces of residual pressureOr to reach the floor peak pressure what crushed crushed?

- Q:What are the product standards of rubber flooring

- Fire prevention: GB8624-2006 regulations, paving materials should be Bf1-s1, T1 level

- Q:Now in France to study, accidentally burned the public kitchen rubber flooring, about 30 square centimeters, I would like to ask the need to replace the entire floor glue? Expensive not expensive.

- As for the housing insurance, I did not have such a thing, the people around him did not have anything on the housing claims, it is not clear. You'd better call to consult, ask how the situation, if you can go, of course, the best insurance.

1. Manufacturer Overview |

|

|---|---|

| Location | Dongguan, China |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Western Europe; North America; Oceania; Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; Korean |

| b)Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Commercial 3000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords