Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

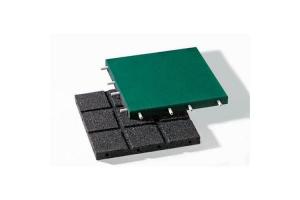

Despription of Track Pad 1000 Series

Track Pad 1000 Series are made of 100% recycled rubber granules.

Track Pad 1000 Series are manufactured by factory with the precasting process and 100% recycled rubber roll. The prefabricate rubber roll are equal thickness, balanced elasticity and smooth surface. Besides, it's convenient for transport and carry. It needs a few of labours and easy tools in the process of installation .There in no need of extra large pave equipments. It also reduce the effects of machinery inconvenience and meet the needs of all kinds of tracks' installation.

Features of Track Pad 1000 Series

Equal thickness, balanced resilience

Smooth surface

Excellent ventilate and water seepage abilities

Fine rating of temperature , cold-resistant and weather resistance

Environmental friendly, non-toxic

Recycled and pollution-free

Application of Track Pad 1000 Series

Underlayer of all kinds of athletic tracks.

Parameters of Track Pad 1000 Series

Density (kg/m3):850 900

Hardness (Shore A ): 58 63

Length (m): 10/15/20m ±5cm

Width (m):1m/1.25m ±5mm

Thickness (mm):7-12mm ±0.3mm (adviced thickness )

- Q:The price of rubber flooring is expensive

- (also called with no scratches no scratches or through anti scratch), currently on the market called dance and dance floor or the floor of the stage is divided into three kinds: first have a scratch of several (different PVC content in different prices) and second paragraph two (no scratches high elasticity, the import side) third, also known as scratch through no scratches. Shanghai Shanghai anti scratch dance floor

- Q:What is the general price of non slip rubber flooring

- You say this is called rubber anti-skid floor, divided into sheet and coil, in general, the ground floor of the plant to do more in order to ensure the stability of the floor.

- Q:What is the size of the plastic floor

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same

- Q:Rubber floor mat can be used for indoor floor sound insulation pad

- Laying sound insulation pad and then laying about 4 cm thick concrete can be directly laid on the ground floor of the rubber sound insulation carpet can be laid.

- Q:What is the difference between plastic and rubber floors? Advantages and disadvantages

- Because of the release of harmful substances, are generally not used for indoor sports venues. For example: everyone should know the plastic track of the outdoor stadium. But at present the domestic "plastic floor" is completely the opposite of the word, we often refer to the "plastic floor" refers to the use of indoor PVC floor. Rubber flooring is made of natural rubber, synthetic rubber and other components of polymer materials made of floor.

- Q:The difference between rubber floor and rubber floor Rubber floor pressure

- There are special parameters for standard test residual dent90kg 250 minutes pressure in the area of 1 square centimeters

- Q:Rubber floor price per square meter

- Rubber floor price per square meter in the 50-150 yuan per square meter. Rubber flooring, as the name implies, is the floor of natural rubber and other synthetic rubber. In appearance, its color is bright, gives a very spiritual sense, for the movement of people is refreshed. And it is also like the texture of soft rubber, when others in the sport on the rubber floor, there will be unlimited power and bounce, very suitable for sports as a venue for sports. At present, the development of domestic rubber flooring

- Q:What's the difference between a wood floor and a rubber floor?

- Wood floor with what we know! Rubber flooring used in hospitals and other large venues

- Q:What color is ivory white rubber floor

- Fresh ivory is generally white or light yellow, after a certain period of play, touch, or place a certain age, the ivory will gradually become yellow, deep yellow, and finally turned into brown. The same piece of ivory color is often different.

- Q:When does the sole of skid resistant rubber and floor rub when can chirp ring?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop

1. Manufacturer Overview |

|

|---|---|

| Location | Dongguan, China |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Western Europe; North America; Oceania; Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; Korean |

| b)Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords