composite decking wooden flooring click locks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2015 hot sale natural Color Composite Decking for sale

一.Product Description:".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

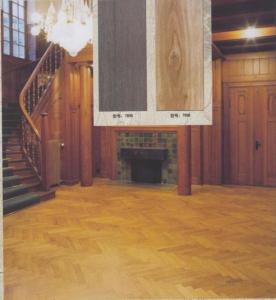

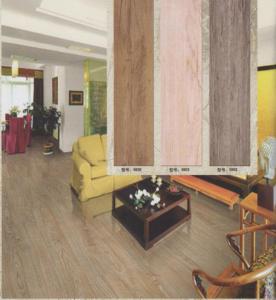

四. More picture for your reference

- Q:Im getting a rabbit and making a c&c cage. what type of flooring should i use?

- I use linoleum flooring I have it attached to wood for the shelves and just under the cage on the bottom. I also use anit-pill fleece blankets since my rabbits love to hide under them and drag them around plus one has bad traction with the lino so they help him when he jumps from shelf to shelf.

- Q:I removed my carpet and put in laminate floor. Do you have to put a sealer for laminate floors. What products can i use to clean laminate floors??

- Just damp mop. they are pretty good about cleaning up.

- Q:My condo is on the 3rd floor & I'm looking to replace the 3/4 white oak floor with 5/8 strand woven bamboo.After removing some of the oak I have found that the sub-floor is a concrete slab (I'm unsure of the thickness) covered by 1/8 of insulayment underlayment. On top of that are two(2) layers of 3/8 plywood screwed to eachother with 3/4 screws. The plywood is not attached to the 1/8 insulayment mat or the concrete slab in any way. So my first question is, is this normal floor construction?My seconod question has to do with the fact that there appears to be green mold between the plywood planks & behind the baseboard. Should I be worried?Thanks in advance. I appreciate any help you can offer.

- It is pretty common to use a plywood underlay in concrete muti-story residential. It acts to keep the floor covering warm and dry. a vapor barrier layer is also a must have. The green mold may not be mold at all, it can be a form on oxidation due to moisture inherent in concrete. If you tear out the plywood, you should replace it for your flooring to last. a strong bleach mix and mop will kill mold.

- Q:My bathroom floor is currently covered with linoleum. I plan to strip the floor of this down to the sub-flooring (wood). What steps will I need to take to ceramic tile my bathroom floor? What things will I have to buy and in what order from start to finish to go from sub-floor to completed ceramic floor?Thanks!10 POINTS to the best answer!!!

- Once the flooring is cleaned and ready to go. You ll need 1/2 cement board. My preference is Durock..Pre cut the Durock and lay into place. Cutting can be done with a hand cutter with a carbide tip or cut with a masonry saw blade (DUSTY!)..Dry fit the pcs, lift and sweep the area again. Spread a thin set with a 1/4 x 1/4 square notched trowel. Set board back into the thin set and walk on it all over. Nail down ( or screw) with 1 1/2 galvanized nails . Use nothing shorter.. 8 in the field and 3/4 along all the seams. Tape all joints with thin set and cement board tape ( this is different from dry wall tape.) Let floor dry 24 hrs.. You are ready to tile. Use the proper trowel for your tile. My recommendations are to use thin set and thin set only for tile setting. Starting from the middle, dry lay tiles out to the walls.. If you have a 1/2 tile or bigger , your good. If less than a 1/2 tile, readjust center of the tile to the center line, this will get you a better wall cut. Straight edges and tape measure to stay square is the best way to go. All this is in accordance with the Tile Council of America guide book, Along with the TCA guidelines. Any other specific questions you can e mail me through my avatar and check my qualifications there. GL

- Q:I just purchased some floor tiles that are suppose to be easy to install. All the direction say you have to do is just attach them to your floor (it sticks on one side) but they won't stick to my floor! (on my bathroom floor, they already have tiny cement tiles on them, nonremovable) i really dont want to take them back, but i need some advice on what i can use to make them work on my bathroom floor, because i hate the tiling thats already there, could someone please help. Mature, helpful answers only, thank you! :)

- Alright first thing first. The self stick tiles you bought are generally used for a quick fix type of project. While they do stick to most surfaces they do not have a commercial type of adhesive on the back of them. Uses: sticking to wood, concrete, vinyl, drywall, painted surfaces temporarily. Wont stick to metal, or tile. That being said. For your application what you want to do is 1) go to hardware store and ask the floor guy for premixed embossed leveler or Ardex floor patch. While you are there get a flat trowel to go with it. The premix is really what you want because it is already at the right consistency for your application. Also sometimes they hide it in the paint dept. But the floor guy will know. 2) go home open the tub and pour about half of in on the floor. The Emboss leveler is self leveling and will flow to the grout joints but use your trowel and help it out some. The goal is not to cover the floor completely but just to fill cracks and make a flat surface. 3) let it dry for a day... once it is dry sweep and start laying your tile. Please keep this in mind. Moisture is the bain of all floor products glued down. With self stick tile there is a seam all the way around the tile for water and moisture to penetrate. You are putting down a temporary floor keep this in mind. Hope this helps, Good luck

- Q:My dog urinated on our laminate wood floors and how the floor seems to have lifted, almost like air bubbles along the seams of the flooring. It looks horrible and I feel like these floors should be resistant to water and other liquids. Can anyone help?

- This Site Might Help You. RE: Can you fix warped laminate flooring? My dog urinated on our laminate wood floors and how the floor seems to have lifted, almost like air bubbles along the seams of the flooring. It looks horrible and I feel like these floors should be re...

- Q:we had a floating floor put down...after all was said and done....the floor looks like it has waffles in it...has anyone seen this? It's light oak...it's ugly and fake looking....speant 13,000 on it...or is this the way it's suppose to look?

- Cant imagine spending 13k on a laminate floor. I did my frontroom last year and I believe I spent like $300 total on the flooring and padding. It took 1 day to do. Is your house like 25k square feet or something? Anyhow, no idea what flooring you picked out, not too sure how you would not have an idea how it would look when done, the planks are large enough to get the idea.

- Q:I just bought a new Honda Fit, and I'm planning on buying floor mats online, but I can't decide between all-season/all-weather floor mats and carpeted mats. I do live in Ohio, so yes, we do get rain and snow, but I don't know, the carpeted floor mats look so nice! What do you think? If I get carpeted floor mats, will they just stain and be hard to maintain?

- any floor matt is better than none, but i suggest you get the all weather ones because, the carpeted ones will eventually stain. If you spill in your car and have rubber floor mats all you have to do is spray them off with a hose and your fine. Rubber floor mats don't fade like carpeted do, and don't hold dirt like the carpet. I also agree carpeted look better but rubber perform better.

- Q:Guo Lin solid wood flooring how?

- It is recommended to shop around, choose their favorite like

- Q:It is estimated that the cost of constructing an office building that is n floors high isC(n)= 3n^2+500n+842thousand dollars. How many floors should the building have in order to minimize the average cost per floor? (Remember, your answer must be a whole number.) ______ floors

- If the cost per floor is C(n) = 3n^2 + 500n + 842 then the average cost per floor would be this function divided by the number of floors n: A(n) = (3n^2 + 500n + 842)/n A(n) = 3n + 500 + 842/n This is the function we want to minimize, so take it's derivative: A'(n) = 3 + 0 + -842/n^2 To find possible max/min values, set the derivative equal to zero: 0 = 3 - 842/n^2 842/n^2 = 3 842 = 3n^2 n^2 = 842/3 n = sqrt(842/3) = 16.753 Since we can only have whole number answers, our answer must be either 16 or 17 A(16) = 600.625 A(17) = 600.5294 So our answer will be 17 floors

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

composite decking wooden flooring click locks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords