Ceramic Fiber Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

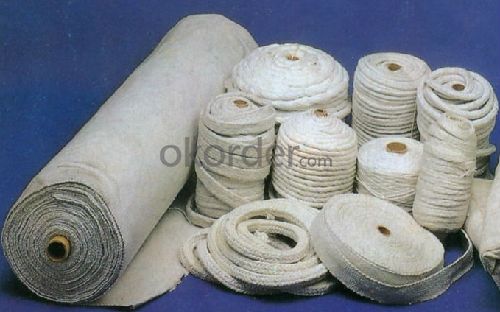

Specifications of Ceramic Fiber Products

Ceramic fiber product could be used by the methods of adhibitting, stuffing, tangling, urivet in different situationsing

Ceramic fiber product is a new inorganic heat insulating and fire resisting material, and it has the characteristics of light weight, small thermal capacity, good capability of heat maintaining and high temperature insulating, good steady of chemical ability, corrosion resistant, oxidation resistant, etc.

Ceramic fiber product uses ceramic fiber as its raw material. The ceramic fiber textile which weaved by special weaving process and manufacture equipment not only has the characteristics of the above ceramic fiber product, but also has the characteristics of high intensity, steady external size, shaking proofing, concussion resisting under high temperature, its physical capability and chemical capability could return to the original status.

Ceramic fiber product is very expedient to use, it could be used by the methods of adhibitting, stuffing, tangling, using rivet in different situation for different purpose. It could be widely used in petroleum, chemical industry, metallurgy, electric, mechanical, shipment, aircraft and car industry for fireproofing, heat insulating, temperature maintaining, high temperature maintaining, high temperature sealing and making other kings of labor safety product. This sort of product is safely to use, has high efficiency of saving energy, and helps to reduce the time of repairing, maintaining, it is an ideal temperature holding and high temperature resisting product in the present industry field.

Main application of Ceramic Fiber Products:

1.stove gate sealing and stove curtain of all sorts of heat insulating industry stove;

2.high temperature flue, bush of pipeline, tie-in of expanding;

3.high temperature insulating, temperature holding of equipment, container, pipeline of petroleum and chemical industry;

4.shield, glove, headgear, headpiece, boot which used under the condition of high temperature;

5.heat insulating cover of cars, enwrap of heavy oil engine, complex apply and brake friction gasket of high-speed racing car;

6.padding, cushion of compressor, valve which used to transporting high temperature liquid and gas;

7.insulating of high temperature wiring

8.fireproofing gate, fireproofing curtain, firefighting blanket, cushion of contacting spark, textile product of heat insulating and enveloping;

9.heat insulating and temperature holding material, and apply and brake friction gasket of spaceflight industry;

10.heat insulating, enveloping of deep-cold equipment, container and pipeline;

11.heat insulating and fireproofing interlayer of archives, bursary, safety of advanced office building, firefighting automatism fireproofing curtain.

Main products:

1.ceramic fiber fabric: thickness: 0.8-3.0mm; width: 500-1000mm

2.ceramic fiber paper(plate): thickness: 0.2-5.0mm; width: 500-1000mm

3.ceramic fiber sting felt: thickness: 25mm, 50mm, 75mm; width: 60x720cm

4.ceramic fiber making up product: produce according to customers request, for example: fireproofing curtain, fireproofing blanket, fireproofing glove, etc.

5.ceramic fiber thread, rope, strap, cannula; diameter: 3-70mm

Packaging & Delivery

Packaging Detail:cartons,or according to customer's requirement

Delivery Detail:within 10days

- Q:I want to start buying products without them.

- Acrylic doesn't block too well so it seems to me that the gauge is too tight around the edgingIf you've added a separate edging after finishing the blanket that's probably what's making it curlTry using a larger hook that should help evening out the curly-ness.

- Q:It Is A Really Cold Day After A Hurricane And I Think My Horse May Need A Blanket, What Should The Temperature Be To Put It On Him (He Is A 14 year Old Quarter Horse Gelding)?

- If your horse is shivering, it tells you that his core body temperature has dropped and his muscles are quivering to increase heat productionSo, if your horse is shivering, you may want to blanket him until it stopsFeeling the skin temperature is not a good indicator of the need for blanketing, since the body reduces blood flow to skin by constricting blood vessels at the skin surface which then increases blood flow (and heat) to the core of the bodyThis makes the skin feel cool even though the body temperature is fineAdding blankets based on cool skin can result in overheating the horse, causing him to sweat and lose more body heat, so it is counterproductiveSweating under a blanket can also lead to development of skin infections such as rain rotRather than blanketing, just being sure he has hay in front of him is all that is usually needed to produce plenty of his own body heatAs hay ferments in the hind gut, it acts like a furnace, producing heat within the horse's bodyMy horses are out without blankets year round, and are never sickIt gets down to minus 30 to 40 F in winterThey can stand outside in any weather and choose to do so despite the fact that they have a very nice shelter to go intoI do provide them with 24/7 access to good grass hay in addition to their hard feed.

- Q:live in FL and would like to know the best type of COLOR and MATERIAL to use for a roof to keep the house coololder cinder block flat roof homecan paint to match roofwill be moving in 5-8 yearswhat would help the house sell the best?thanks for your time.

- makes No difference.

- Q:Why does a fibre glass stove top crack spontaneously? This morning I found the top to be uniformly cracked?

- What an odd material to make a stove top out ofNo one in their right mind would make a stove top out of flammable thermoset resins and fiberglassI can see their ad nowCall 1-800-CRAZY STOVE !!!! Now with more flammability!!! Comes with a free 60 day monitoring contract with ADT!! Good thing it bustedChuck that thing as far as you can and get a proper stove-EDIT- OK, makes a lot more senseYou have a glass ceramic cooktopThese cooktops are formulated to have a near 0 thermal expansion curve over a wide range of temperaturesThe ceramic used in the cooktop actually has a negative thermal expansion coefficient and when mixed with a borosilicate or vaseline glass, a near 0 can be attainedThermal shock doesn't really figure into these kinds of cooktopsPhysical shock doesSmall scratches on the glass can propagate at over 20,000 ft/secThat is one of the reasons why you don't move a pot or pan back and forth over one of these things like you would on a gas stove topI would guess that the cooktop was simply old, scratched, and did not posses a perfect 0 thermal expansion coefficient10 years? Yeah, that's about rightSorry manNot your fault, but you will have to get a new one.

- Q:Ive gained alot of weight since getting pregnant Im only 23 and I want my body back asap

- There is usually a myriad of solutions starting from a few simply do not care to scientific problems to the truth that as ladies hit their center age years their metabolism robotically slows down anyhow whether or not they've a scientific challenge or no longerI feel while weight may not come off effortless many ladies discover it discouraging sufficient that it then turns into simply as so much of a mental challenge as probably a bodily oneI've by no means been a toothpick, correctly while I was once in JrHigh I was once constantly referred to as the fats lady for the reason that I had reached my grownup peak and weight of five'three and one hundred thirty lbsFor me that is typical and a few men do not like that and a few do and I'm ok with thatThe ones that do not love it, that is their optionI'm healthful - I performed 3 sporting activities a 12 months till the age of 30 while I acquired marriedI even have Hypothyroidism so I must rather be strict approximately my vitamin for the reason that I understand if I positioned extra weight on I could have an excessively tough time taking it off once more.

- Q:ok for my clas i need 2 make a healthy bunny for but its kinda hard so i need somehelp on that sutff post me plz

- 31-14% Protein? I don't understand Purina Show Formula is for lighter breedsYou just can't overfeed or you will get an overweight rabbitMany store rabbit foods have those treat balls that are full of fat and sugaryou get an overweight rabbit easily What breed of rabbit is this supposed to be? What weight is it supposed to be and how overweight is it? Small breeds should be given only 1/2 Cof feed a day (unless they have a higher metabolism and don't have enough weight on thembut that is rare)but then they can get all the grass hay they wantPurina Show Formula: 16% Protein 3.5% Fat (contains essential oils for fur) 17%-20.4% Crude Fiber

- Q:I have very coarse and thick hairI'm also a good swimmer, my hair is very damaged and dry from the chlorineAny suggestions? Thanks

- Aluminum is plain wrong! dutch ovens are suppose to be cast iron.but if you insist on poisoning your self go for it!

- Q:I feel like drinking liquids rather than eating solid food would help me lose weight easierBy liquid, I mean juices, smoothies, protein shakes, soup, applesauce, yogurt, etcbut still getting the same nutritional needs as a regular diet with solid foods.Anyone had any experience with this?

- ultimately yet another possibility to take a smash! loopy day! I became interested in many witchcraft appropriate matters due partly to looking Wicca as a faith that usually happening witchcraft, and partly becauase i replaced into raised on a farm and my mom taught me many organic treatments for issues starting to be up - so i replaced into interested in herbs, aromatherapy, some holistic healing and problems with that natureadditionally reading/working with tarot - and that stemmed from Wicca/Witchcrafti'm a very cunning person and that i love to do crafts when I relatively have the time - so i've got included the two and make witchcraft crafts (like the pentacle wreath adorned with dried flowers striking on my front door) - yet at the instant i are turning out to be extra into writing and that i tend to place in writing a great variety of poems and issues from a Pagan attitudequite lots each and every time i'm no longer at artwork, or with friends/relatives, or outdoors on a nature walk with the dogs.i'm the two analyzing (books or on line - religious blogs, boards like this, etc.) or engaged on a undertaking appropriate to a minimum of one in each and every of my somewhat some hobbies as suggested above.

- Q:What's the best, most affordable bulky weight wool yarn to use for knitting projects?

- Buy visqueen and and start at one side and move across your studs and wallsYou will need to staple as you goThis creates a vapor barrier, then put your insulation over thisReynolds foil would put you in the poor houseI think what you are seeing is insulation with aluminum on one side75 is way hot for rabbits55 or 60 would be fine even lowerRaised them for years in outside hutches and they made out fine.

- Q:Dont say peek a boo or hide and seek or coloringThose are all givensPlus he's a little old for peek a booMy son is 2 and it's so cold outside that our normal routine is all messed upWe usually spend up to 3 hours a day outsideBut since it's in the 30's today that won't be an optionMy son has a large play room and tons of toys but I wanted some easy activites that we can do togetherANy ideas?? He 's 2 btw)

- If there's a shop nearby, buy one of these ready-bake cake mixes with a childhood character [Scooby-Doo cakes for example] and make him the Head Chef or the Big Chef, and obviously watch over him, and let him make the cakesI know he's only 2, but being in charge of something like this will give him independance, and will also introduce some structure into his daily routineAnd be careful - things may get a little messy! :)

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Fiber Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords