Ceramic Fiber Blanket Low Thermal Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket Low Thermal Conductivity

Description for Ceramic Fiber

Ceramic fiber is made from high quality clay, high purity alumina and silica oxides by spun or blown process.

Ceramic fiber has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fiber also has difference,and they are suitable for different workong temperatures.

Ceramic fiber can be used after optional cutting .When ceramic fiber storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for Ceramic Fiber

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fiber

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

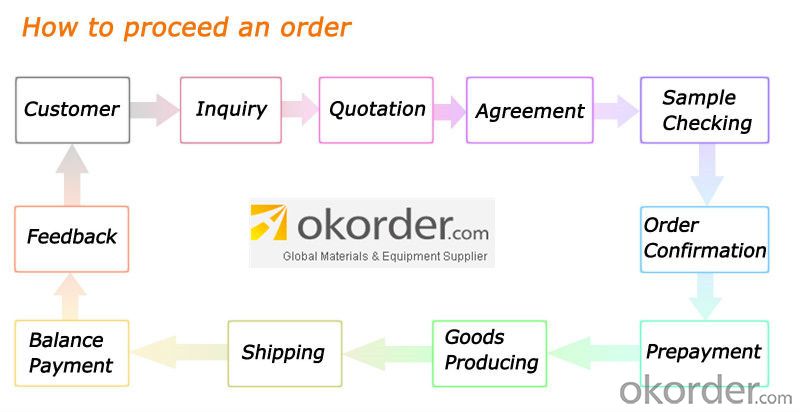

Images for Ceramic Fiber

◆Product Process

◆Packaging

FAQ

Can we accept OEM for Ceramic Fiber ?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us,okorder will provide our best products and services for you!!

- Q:Hey guys! I've lost 120 pounds so far and I only have 30 pounds left! I am thinking about eating ground turkey.alot of it instead of anything else.I buy the 99% fat free breast which has only 520calories a poundI'm thinking of eating 2 pounds of it a day and 500 calories of other things (including oil)Is this bad for me If i know i can do it and I dont mind? Also.is there a way to cook ground turkey without using oil? Can i bake it? Can i boil it?thx in advance!

- you can get straightening balm at any retail/drugstore, this will help keep it straight for long wearuse high heatand try to minimize the time you take to straighten so you dont damage your hair! :)

- Q:What are the benefits for adding more fiber to my diet? I have started eating nature's valley cruchy gronola and also added benefiber to my dietPls let me know the pros and cons?

- Was going to have my tea in a minute.youve just completely put me off my food.

- Q:The reprocessing of recycled paper stock in the manufacturing of new paper products which are sold as quot;Made from Recycled Paperquot; and quot;greenquot; requires a great deal of energy (in the collection and recycling industry itself as well as at the factory) and requires large quantities of polluting chemicalsIs the retail price of paper products manufactured using the maximum practical percentages of recycle paper so much higher than quot;new paperquot; product prices because more resources are used?Secondly, do industry analysts expect the price premium we must pay for recycled paper products at retail to continue or will the price difference eventually shrink?

- It depends on the product you are talking aboutEnd use products, such as attic insulation, toilet paper and facial tissues are almost never made with 100% virgin paperWriting paper, on the other hand, may require extra work to get it to a quality that consumers will accept and this is reflected in the price.

- Q:No worries, I know these aren't permenant fixes.but I just found out about a last minute trip I'm to go on see some familiar faces I haven't seen in a while.so even if it's only a quick 5 or 10 lb fix.I'll take it I'll be safe.and that'll be the last you'll hear of me asking for crash diet advice! Honest:)

- Because you worked out before your Dr appointment it possible that you work your sugar level down but once you go for your three hour test regardless of what you do before it will show up because the sugar drink that they give you cannot be handle by a diabetic but if your sugar was in range you may even be borderline diabetic or type twoI wish you luck and hope everything turns out ok.

- Q:I'm building the best posible coil for a project, I need it to induce the most current posible, I'm not measuring costs but resultsIt's a coil that induces current from moving magnets around a disk a bit bigger than a regular CD, magnets facing outwards, polarity N-S-N-S-etc.I hear that supermalloy is extremely better than iron, and in other places I hear that it's not that different.Has anybody had any experience with supermalloy for the core?If not, which would be the most important issues in terms of construction of the coil (besides number of turns and type of cable)? Any experience in building coils would be greately appreciated.

- maybe wax paperIt is used in the oven, so it would last through hot glue, too.

- Q:I'm trying to teach myself how to crochetEveryone says it is easy, but I just can't do it!! I can knit just fine, but crocheting is a whole other story! I thought that if I got the biggest needle I could find, it would make things easierI bought a 9mm, which I found out online is a size MI can make the basic chain stitch, but when I go back to do the first crochet, I can't get the dang needle through! Is this because I bought to big of a hook for basic yarn? What size should a beginner start out with? HELLLP! I want to be craftyLOL.

- Hahah- thats something i would do with my friends! :) lol sooo with my friends, we just go outside and get wetyou can make a slip n' slide with a tarp and a hoseIt's better going down a hill but also fun without oneYou could go outside for a walk, or have a lemonade stand on a busy street to make moneyYou could also make up a dance outside on the grass? Bake a cke, or brownies or somethingYou could bake cupcakes and then everyone could decorate themYou should get food coloring and make cool icing designsHave Funn!!

- Q:im trying to lose weight, i heard a fiber and protein keeps u full and satisfied longer so if i drink whey protein shakes, high fiber cereal, whole wheat bread and fruits will i lose weight

- i had enjoyed a number of the following locations when i was single and now, with my wife- library - Central Park - inside my car, parked near the beach(the beach was nice, but too sandy and would be too irritating for your lady) - on a boat - on the top tier of a double decker sight-seeing bus in NYC- on a big gymnastic pad/mat inside the gym at school - in our tent while camping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket Low Thermal Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords