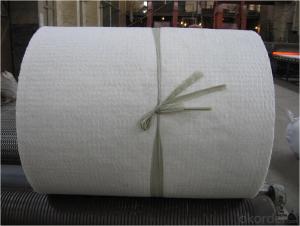

Waterproof Thermal Blanket

Waterproof Thermal Blanket Related Searches

Glass Wool Tape Fiberglass Insulation Blanket Fiberglass Thermal Insulation Kimmco Glass Wool Insulation Waterproof Thermal Blanket Glass Wool Thermal Conductivity Thermal Conductivity Glass Insulation WoolHot Searches

Used Foam Board Insulation For Sale Plastic Roof Tiles For Sale Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Gypsum Board Price Per Sheet In India High Density Mdf Board Suppliers Calcium Silicate Pipe Insulation Price 5 8 Type X Gypsum Board Price Calcium Silicate Board Suppliers In Uae Gypsum Board Price Per Sheet Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Pre Laminated Board Price List Durock Cement Board Price Century Waterproof Plywood Price List Greenply Waterproof Plywood Price List Solar Inverter Mounting BoardWaterproof Thermal Blanket Supplier & Manufacturer from China

Okorder.com is a professional Waterproof Thermal Blanket supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Waterproof Thermal Blanket firm in China.Hot Products

FAQ

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

- Fiberglass mat tissue can indeed be utilized for insulation purposes. It finds widespread application within the construction sector, serving as an effective material for thermal and sound insulation. Comprised of delicate glass fibers intricately woven into a mat-like formation, this tissue structure effectively captures air, establishing a barrier that minimizes heat transfer. Consequently, it ensures insulated spaces retain a pleasant temperature. Moreover, fiberglass mat tissue boasts resistance against moisture, fire, and pests, rendering it an excellent insulation option across diverse situations.

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass roofs. It is commonly used in the construction industry as a reinforcing material for various applications, including roofs.

- Yes, fiberglass mat tissue can be used for insulating metal buildings. Fiberglass mat tissue is a lightweight and flexible material that can provide effective thermal insulation for metal structures. It is commonly used as a layer between the metal panels and the interior of the building to prevent heat transfer and improve energy efficiency. Additionally, fiberglass mat tissue is resistant to moisture and does not promote the growth of mold or mildew, making it an ideal choice for insulating metal buildings. However, it is important to ensure proper installation to maximize its insulation properties and prevent any gaps or air leaks.

- Yes, fiberglass mat tissue requires special precautions during cutting. It is important to wear protective clothing, gloves, and a respirator to prevent inhaling the fine fibers that can be released during the cutting process. Additionally, using a sharp blade or scissors is recommended to ensure clean cuts and minimize the risk of fraying or splintering.

- Fiberglass mat tissue performs exceptionally well in terms of moisture absorption. Due to its composition of multiple layers of glass fibers and a binder, it can effectively resist moisture penetration, making it highly resistant to water absorption. This property makes fiberglass mat tissue an ideal material for various applications where moisture resistance is crucial, such as in roofing, insulation, and composite manufacturing.