Glass Fiber Chopped Strand Mat (CSM) for Boat

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Introduction

Chopped strand mats are made of chopped strands of 50mm in length, which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields, such as hand lay-up, filament winding and molding process. The typical products are panels,tanks,boats,automotive parts, cooling towers, pipes and so on!

2.Technical data

| Model No.: | EMC100 | |

| Weight: | 100 grams per sq/m | |

| Width: | up to 3300mm | |

| Loss on Ignition: | 2-7.5 | |

| Moistrure: | ≤0.5% | |

3.Advantages

1.Excellent compatibility with resin,the surface of the product is smooth,the sealing is good,and the water and chemical resistance are strong.

2.Excellent heating resisitance.

3.Good overmolding performance,easy to cut,easy to operate,suitable for making various shapes and complex product.

4.Good resin permeability,fast soaking speed,faster curing speed and higher production efficiency.

4.Application

5.Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

6.Serial parameter:

| Model No. | Weight | Width | Loss on Ignition | Moistrure | Use And Craftwork | |

| (grams per sq/m) | (inch) | (mm) | (%) | (%) | ||

| AEMC | 100/150/200/220 | 41-130 | 1040-3300 | 4-10 | ≤0.2 | Specialized for Automotive |

| EMC-E | 300/450/600 | 41-130 | 1040-3300 | 2-6 | ≤0.2 | Specialized for Transformer |

| EMC-R | 200/300/450 | 41-130 | 1040-3300 | 2-5 | ≤0.2 | Hand Lay-up / FRP |

| EMC-M | 200-900 | 41-130 | 1040-3300 | 2-5 | ≤0.2 | Mode |

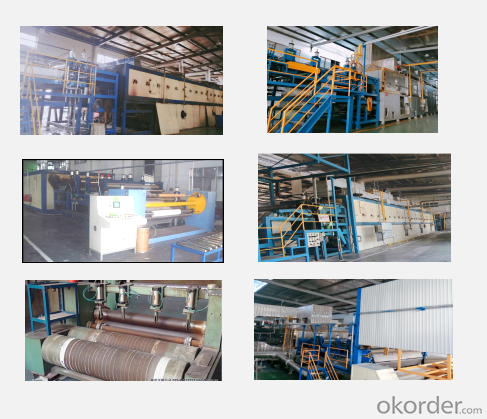

7.Our company:

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within15-20 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.

- Q:Can fiberglass mat tissue be used for insulation?

- Fiberglass mat tissue can indeed be utilized for insulation purposes. It finds widespread application within the construction sector, serving as an effective material for thermal and sound insulation. Comprised of delicate glass fibers intricately woven into a mat-like formation, this tissue structure effectively captures air, establishing a barrier that minimizes heat transfer. Consequently, it ensures insulated spaces retain a pleasant temperature. Moreover, fiberglass mat tissue boasts resistance against moisture, fire, and pests, rendering it an excellent insulation option across diverse situations.

- Q:What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q:How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue is generally effective at resisting moisture vapor. It acts as a barrier, preventing the passage of water vapor and making it suitable for moisture control in applications like roofing and insulation. To enhance the moisture vapor resistance of fiberglass mat tissue, it can be combined with other materials like vapor barriers or moisture-resistant coatings. These additional layers provide extra protection against moisture infiltration, improving the overall performance of the fiberglass mat tissue. However, it should be noted that the moisture vapor resistance of fiberglass mat tissue can vary depending on factors such as thickness, density, and composition. Thicker and denser mats tend to offer higher resistance, while the presence of manufacturing additives or coatings can also affect the material's properties. In conclusion, fiberglass mat tissue is known for its moisture vapor resistance, but its performance may be influenced by various factors. It is recommended to consult product specifications or manufacturers' recommendations to determine the specific moisture vapor resistance of a particular fiberglass mat tissue product.

- Q:Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q:How is fiberglass mat tissue used in the production of chemical storage tanks?

- Fiberglass mat tissue is utilized in the production of chemical storage tanks as a reinforcement material. It is typically combined with resin to form a composite material that provides strength, durability, and resistance to various chemicals. The fiberglass mat tissue is layered within the tank structure to enhance its structural integrity and prevent leakage. During the manufacturing process, the fiberglass mat tissue is impregnated with resin, usually polyester or epoxy, to create a strong bond between the fibers and the matrix. This impregnated mat is then placed on a mold or mandrel and subsequently covered with additional layers of resin and mat, forming a laminate. The number of layers and thickness can vary depending on the desired tank specifications and the chemicals it will store. The combination of the fiberglass mat tissue and resin provides excellent corrosion resistance, making it suitable for storing a wide range of chemicals. Fiberglass is inherently non-reactive and can withstand exposure to harsh chemicals, acids, and alkalis without degrading or compromising the tank's structural integrity. This makes fiberglass mat tissue a preferred material for chemical storage tanks, as it ensures the safety of the stored chemicals and minimizes the risk of leaks or contamination. Additionally, the use of fiberglass mat tissue allows for the production of tanks with complex shapes and sizes, as it can be easily molded and formed into various configurations. This flexibility in design ensures that chemical storage tanks can be tailored to specific requirements and can be efficiently integrated into different industrial applications. In summary, fiberglass mat tissue plays a crucial role in the production of chemical storage tanks by reinforcing the tank structure, providing resistance to chemicals, and enabling the fabrication of tanks with diverse shapes and sizes. Its combination with resin creates a durable and corrosion-resistant composite material, ensuring the safe storage of chemicals in various industrial settings.

- Q:Can fiberglass mat tissue be used for insulating metal buildings?

- Yes, fiberglass mat tissue can be used for insulating metal buildings. Fiberglass mat tissue is a lightweight and flexible material that can provide effective thermal insulation for metal structures. It is commonly used as a layer between the metal panels and the interior of the building to prevent heat transfer and improve energy efficiency. Additionally, fiberglass mat tissue is resistant to moisture and does not promote the growth of mold or mildew, making it an ideal choice for insulating metal buildings. However, it is important to ensure proper installation to maximize its insulation properties and prevent any gaps or air leaks.

- Q:Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops.

- Q:Is fiberglass mat tissue suitable for insulation in educational facilities?

- Yes, fiberglass mat tissue is suitable for insulation in educational facilities. Fiberglass mat tissue is commonly used in insulation applications due to its excellent thermal insulation properties. It is a lightweight and cost-effective material that can effectively insulate buildings, including educational facilities, against heat loss or gain. Fiberglass mat tissue is also known for its fire-resistant properties, which is an important aspect to consider in any building, especially in educational facilities where the safety of students and staff is a top priority. Additionally, fiberglass mat tissue is easy to install and does not require extensive maintenance, making it a convenient choice for insulation in educational facilities.

- Q:What is fiberglass mat tissue?

- Fiberglass mat tissue is a non-woven material made from fine glass fibers that are randomly laid and bonded together. It serves as a reinforcement material in various applications, providing strength, durability, and improved mechanical properties to the final product.

- Q:Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not typically used for making furniture. Fiberglass mat tissue is a lightweight material that is commonly used in industries such as construction, automotive, and aerospace for its strength and durability. It is often used as a reinforcement material in the production of composite materials, such as fiberglass-reinforced plastic (FRP) or fiberglass-reinforced polymers (FRPs). While fiberglass may offer some advantages in terms of strength and resistance to moisture, it is not a commonly used material in furniture manufacturing. Furniture typically requires materials that are aesthetically pleasing, comfortable, and easy to work with. Fiberglass can be difficult to shape, may not provide the desired texture or visual appeal, and can be uncomfortable to sit or lie on. Instead, furniture manufacturers typically utilize materials such as wood, metal, plastic, upholstery fabrics, and foam for creating furniture pieces. These materials offer a wider range of options in terms of design, comfort, and customization, making them more suitable for furniture production.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Fiber Chopped Strand Mat (CSM) for Boat

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords