E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

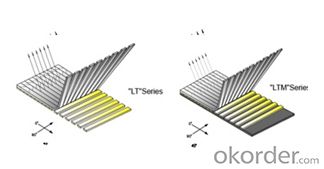

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:Is fiberglass mat tissue resistant to acids?

- Fiberglass mat tissue is generally resistant to acids, thanks to its excellent corrosion resistance properties. This resistance extends to various acids. When combined with resin, fiberglass mat becomes a strong and durable material that can withstand exposure to a wide range of chemicals, including acids. However, it's important to note that the resistance of fiberglass mat tissue can still be affected by the specific type and concentration of acid. Highly concentrated or aggressive acids, in some cases, may cause damage or degradation to the material over time. Consequently, it is always advisable to consider the specific acid being used and consult the manufacturer's recommendations for compatibility before exposing fiberglass mat tissue to an acidic environment.

- Q:Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q:How is fiberglass mat tissue used in the aerospace industry?

- Fiberglass mat tissue is used in the aerospace industry primarily for its lightweight and high strength properties. It is commonly used as a reinforcement material in the manufacturing of aircraft components such as wings, fuselage, and tail structures. The fiberglass mat tissue provides structural integrity and enhances the overall durability of these components, while also offering excellent resistance to corrosion and high temperatures.

- Q:Does fiberglass mat tissue require any special surface treatments before application?

- Yes, fiberglass mat tissue typically requires a special surface treatment before application. This treatment usually involves priming the surface with a suitable resin or adhesive to ensure proper adhesion and bonding between the fiberglass mat tissue and the substrate.

- Q:How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue performs well in terms of moisture vapor resistance. It is highly resistant to moisture vapor, preventing its penetration and protecting the underlying materials. The tightly woven fibers of the tissue create a barrier that limits the transfer of moisture, making it an effective choice for applications where moisture control is crucial.

- Q:Is fiberglass mat tissue safe to handle?

- Yes, fiberglass mat tissue is generally safe to handle. However, it is important to take certain precautions when handling fiberglass to minimize any potential risks. Fiberglass mat tissue is made up of fine fibers of glass, and if not handled properly, these fibers can become airborne and may cause irritation to the skin, eyes, and respiratory system. To ensure safety, it is recommended to wear personal protective equipment such as gloves, safety goggles, and a dust mask when handling fiberglass mat tissue. This will help prevent direct contact with the skin, eyes, and inhalation of any loose fibers. It is also advisable to work in a well-ventilated area to reduce the concentration of airborne fibers. In addition, it is essential to handle fiberglass mat tissue with care to prevent any physical injuries. The fibers can be sharp and may cause cuts or abrasions if mishandled. It is advisable to use appropriate tools and techniques to cut, shape, or manipulate the material. Furthermore, it is important to follow proper disposal guidelines for fiberglass waste. Avoid sweeping or vacuuming the area where fiberglass mat tissue has been handled, as this can disperse fibers into the air. Instead, use damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and reduce the risk of exposure. By following these safety precautions and handling guidelines, the risks associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q:How does the width and length of fiberglass mat tissue affect its application?

- Various aspects of fiberglass mat tissue application can be greatly influenced by its width and length. The width of the mat tissue has a significant impact on both coverage area and ease of installation. A wider mat tissue can cover a larger surface area, reducing the number of individual sheets needed for a project. This can result in time and effort savings, particularly for large-scale applications. Moreover, the width of the mat tissue can also affect the overall strength and durability of the final product. A wider mat tissue provides greater reinforcement, making it suitable for applications that require enhanced strength and stability. For instance, it can be utilized in the construction of structural components or high-stress areas. On the other hand, the length of the mat tissue affects convenience and flexibility during installation. Longer rolls of mat tissue enable continuous installation without the need for frequent seams or joints. This advantage is particularly valuable when working on substantial projects, as it minimizes potential weak points and enhances the overall integrity of the fiberglass application. Furthermore, the length of the mat tissue also impacts the ease of handling and transportation. Longer rolls can pose challenges in terms of maneuverability and transport, especially in confined spaces or through narrow doorways. Consequently, it is crucial to consider the length based on the accessibility and logistics of the specific application site. To summarize, both the width and length of fiberglass mat tissue play vital roles in its application. The width influences coverage area, strength, and durability, while the length affects convenience, flexibility, and handling during installation. Taking these factors into account enables a more efficient and successful application of fiberglass mat tissue across various industries and projects.

- Q:Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. Fiberglass mat tissue is a versatile material that is commonly used for reinforcing and repairing fiberglass structures, including shower stalls. It is designed to provide strength and durability to the repaired area, ensuring a long-lasting and reliable fix. When used in combination with a suitable fiberglass resin, fiberglass mat tissue can effectively repair cracks, holes, and other damages in fiberglass shower stalls. However, it is important to carefully follow the manufacturer's instructions and guidelines for proper application and curing to ensure the best results.

- Q:Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass RVs. Fiberglass mat tissue is a lightweight, flexible material that is commonly used for reinforcing and repairing fiberglass structures. It is designed to be easily molded and shaped to fit the contours of the damaged area, making it ideal for repairing RVs, which often have curved surfaces. To repair a fiberglass RV using fiberglass mat tissue, the damaged area needs to be cleaned and prepared by removing any loose or damaged fiberglass. The mat tissue is then cut to the appropriate size and shape to cover the damaged area. A suitable fiberglass resin or adhesive is applied to both the damaged area and the backside of the mat tissue. The tissue is then carefully placed over the damaged area and pressed down to ensure proper adhesion. Once the repair is complete, the fiberglass resin or adhesive is allowed to cure according to the manufacturer's instructions. After curing, the repaired area can be sanded, primed, and painted to match the rest of the RV's exterior. It is important to note that fiberglass mat tissue is typically used for smaller repairs and cosmetic damage. For larger structural repairs, it may be necessary to use additional reinforcement materials such as fiberglass cloth or woven roving. It is recommended to consult with a professional or refer to specific repair guides for detailed instructions on repairing fiberglass RVs.

- Q:How does the porosity of fiberglass mat tissue affect its performance?

- The porosity of fiberglass mat tissue plays a significant role in determining its performance. Porosity refers to the density of tiny pores or holes in the material, which affects the material's ability to absorb and hold fluids, as well as its strength and durability. Firstly, the porosity of fiberglass mat tissue influences its absorption capability. A higher porosity allows the tissue to absorb more fluids, such as resins or binders, during the manufacturing process. This absorption is crucial as it ensures better adhesion between the fiberglass mat and the bonding material, resulting in a stronger and more durable end product. Secondly, the porosity of the fiberglass mat tissue affects its strength and stiffness. Lower porosity generally indicates higher density and a more tightly packed structure, resulting in increased strength and stiffness. This is beneficial in applications where the material needs to withstand high mechanical stresses or act as a structural component. Additionally, the porosity of the fiberglass mat tissue impacts its thermal and acoustic insulation properties. Higher porosity typically leads to better thermal and acoustic insulation due to the increased number of air pockets within the material. These air pockets act as barriers, reducing heat transfer and sound transmission, making the material suitable for applications requiring thermal or acoustic insulation. Furthermore, the porosity of fiberglass mat tissue can influence its filtration capabilities. If the material has a high porosity, it can trap and hold particles more effectively, making it suitable for use in filtration systems. Conversely, a low porosity may allow for better flow rates, making it more suitable for applications where fluid permeability is important, such as drainage applications. In summary, the porosity of fiberglass mat tissue affects its performance in various ways. It determines its absorption capability, strength, stiffness, thermal and acoustic insulation properties, filtration capabilities, and fluid permeability. Therefore, understanding and controlling the porosity of fiberglass mat tissue is essential to ensure optimal performance in a wide range of applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords