All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Are there any specific guidelines for bonding fiberglass mat tissue to substrates?

Yes, there are specific guidelines for bonding fiberglass mat tissue to substrates. These guidelines typically include preparing the substrate surface by cleaning it thoroughly, ensuring it is free from dust, oil, or any other contaminants. The next step involves applying an appropriate adhesive or resin to the substrate, making sure it is evenly distributed. The fiberglass mat tissue is then carefully laid over the adhesive or resin, ensuring it is fully embedded and covering the entire area. Pressure may be applied to ensure proper adhesion, and the bonding process is typically followed by curing or drying according to the instructions provided by the manufacturer of the adhesive or resin. It is important to follow these guidelines to achieve a strong and durable bond between the fiberglass mat tissue and the substrate.

How is fiberglass mat tissue different from fiberglass cloth?

Fiberglass mat tissue is different from fiberglass cloth in terms of its construction and application. Fiberglass mat tissue is made by bonding thin strands of fiberglass together with an adhesive to form a mat-like material. It is typically used as a reinforcement layer in laminates, providing strength and impact resistance. In contrast, fiberglass cloth is woven from continuous strands of fiberglass, resulting in a flexible and fabric-like texture. It is commonly used for applications that require a combination of strength, flexibility, and a smooth finish.

Can fiberglass mat tissue be used for reinforcing electrical enclosures?

No, fiberglass mat tissue is not suitable for reinforcing electrical enclosures as it does not possess the necessary electrical insulation properties required for such applications.

Can fiberglass mat tissue be used for duct board manufacturing?

Yes, fiberglass mat tissue can be used for duct board manufacturing. It is commonly used as a reinforcement material in the production of duct boards, providing strength, durability, and insulation properties to the final product.

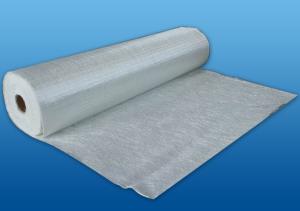

Wholesale Fiberglass Mat Tissue from supplier in Germany

With our strong partnership with CNBM, we can ensure efficient sourcing and timely delivery of Fiberglass Mat Tissue products to our customers in Germany. Our team of experts is dedicated to providing personalized customer service and technical support, ensuring that you have the right product for your specific requirements.

We understand the importance of quality and reliability in the construction industry, which is why we only work with trusted manufacturers and suppliers. Our Fiberglass Mat Tissue products are made from high-quality materials and undergo rigorous quality control processes to meet international standards.

Whether you need Fiberglass Mat Tissue for roofing, insulation, or other applications, we have a wide range of options available. Our sales team can provide you with detailed product information, competitive pricing, and customized quotations to meet your budget and project requirements.

In addition to our sales and procurement services, we also offer technical support and guidance throughout your project. Our team of experts can assist you with product selection, installation advice, and troubleshooting, ensuring that you have a smooth and successful project.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations and provide you with the best possible service. Contact us today to learn more about our Fiberglass Mat Tissue products and how we can support your projects in Germany.

We understand the importance of quality and reliability in the construction industry, which is why we only work with trusted manufacturers and suppliers. Our Fiberglass Mat Tissue products are made from high-quality materials and undergo rigorous quality control processes to meet international standards.

Whether you need Fiberglass Mat Tissue for roofing, insulation, or other applications, we have a wide range of options available. Our sales team can provide you with detailed product information, competitive pricing, and customized quotations to meet your budget and project requirements.

In addition to our sales and procurement services, we also offer technical support and guidance throughout your project. Our team of experts can assist you with product selection, installation advice, and troubleshooting, ensuring that you have a smooth and successful project.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations and provide you with the best possible service. Contact us today to learn more about our Fiberglass Mat Tissue products and how we can support your projects in Germany.

Hot Search

- Fiberglass Chopped Strand in Nepal

- Fiberglass Mesh Cloth in Dominican

- Composite Pipes in Malaysia

- FRP Pultrusion Profiles in Kuwait

- Fiberglass Mat Tissue in Zambia

- Fiberglass Fabrics in Switzerland

- Fiberglass Mesh in Iraq

- Composite Tank in Bolivia

- Fiberglass Mesh tape in Norway

- Polymer in South Africa