All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you calculate the thermal expansion of aluminum coils for different temperatures?

To calculate the thermal expansion of aluminum coils for different temperatures, you need to know the coefficient of thermal expansion (CTE) of aluminum. The CTE represents the amount of expansion or contraction a material undergoes with a change in temperature. For aluminum, the CTE is typically around 22.2 x 10^-6 per degree Celsius.

To calculate the thermal expansion, you can use the equation:

ΔL = α * L * ΔT

Where:

ΔL is the change in length

α is the CTE of aluminum

L is the initial length of the coil

ΔT is the change in temperature

By plugging in the appropriate values, you can calculate the thermal expansion of aluminum coils for different temperatures.

How do you choose the right alloy for specific applications of aluminum coils?

Choosing the right alloy for specific applications of aluminum coils involves considering various factors such as required strength, corrosion resistance, formability, weldability, and cost. Conducting a thorough analysis of the application requirements, including environmental conditions and mechanical properties, helps in determining the appropriate alloy. Additionally, consulting with experts, such as metallurgists or suppliers, and referencing industry standards or guidelines can assist in making an informed decision that ensures optimal performance and longevity of the aluminum coils.

What are the considerations for using aluminum coils in applications exposed to corrosive chemicals?

When considering the use of aluminum coils in applications exposed to corrosive chemicals, there are several important factors to take into account. Firstly, aluminum is generally resistant to corrosion in many common environments, but it may not be suitable for highly acidic or alkaline conditions. Therefore, the specific corrosive properties of the chemicals involved must be carefully evaluated.

Secondly, the thickness and quality of the protective coating on the aluminum coils should be considered. A robust and corrosion-resistant coating can provide an added layer of protection against chemical reactions.

Additionally, the temperature and concentration of the corrosive chemicals should be taken into consideration. Elevated temperatures and high concentrations can accelerate corrosion rates and potentially compromise the performance of aluminum coils.

Lastly, regular maintenance and monitoring should be implemented to detect any signs of corrosion early on. This can involve regular inspections, cleaning, and applying appropriate protective measures to mitigate any potential damage.

In summary, the considerations for using aluminum coils in applications exposed to corrosive chemicals include evaluating the chemical properties, ensuring a suitable protective coating, considering the temperature and concentration of the chemicals, and implementing regular maintenance and monitoring protocols.

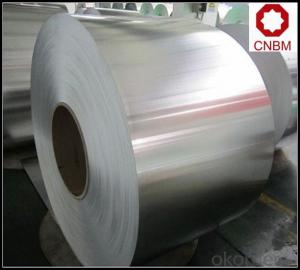

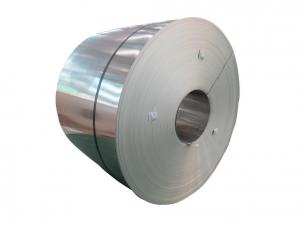

Wholesale Aluminum Coils from supplier in Germany

Our team of experts is well-versed in the aluminum industry and can assist you in selecting the right Aluminum Coils for your specific applications. We offer a wide range of grades, sizes, and finishes to ensure that we can meet your unique specifications.

In addition to our high-quality products, we also provide exceptional customer service. Our dedicated sales team is available to assist you throughout the entire procurement process, from providing quotes and samples to arranging delivery and logistics. We understand the importance of timely and efficient service, and we strive to exceed your expectations in every aspect of our business.

Furthermore, we offer technical support services to help you optimize your use of Aluminum Coils. Our team of engineers and technicians can provide guidance on product selection, installation, and maintenance, ensuring that you achieve the best possible results with our products. We believe in building long-term partnerships with our customers, and we are committed to supporting your success.

As a subsidiary of CNBM, one of the leading companies in the global aluminum industry, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and advancements, ensuring that we can provide you with the latest and most innovative Aluminum Coils solutions.

In summary, when you choose us as your supplier of Aluminum Coils in Germany, you can expect a comprehensive range of products, exceptional customer service, technical support, and access to the global expertise of CNBM. We are confident that we can meet all your Aluminum Coils requirements and contribute to the success of your projects. Contact us today to discuss your specific needs and let us be your trusted partner in aluminum procurement.

In addition to our high-quality products, we also provide exceptional customer service. Our dedicated sales team is available to assist you throughout the entire procurement process, from providing quotes and samples to arranging delivery and logistics. We understand the importance of timely and efficient service, and we strive to exceed your expectations in every aspect of our business.

Furthermore, we offer technical support services to help you optimize your use of Aluminum Coils. Our team of engineers and technicians can provide guidance on product selection, installation, and maintenance, ensuring that you achieve the best possible results with our products. We believe in building long-term partnerships with our customers, and we are committed to supporting your success.

As a subsidiary of CNBM, one of the leading companies in the global aluminum industry, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and advancements, ensuring that we can provide you with the latest and most innovative Aluminum Coils solutions.

In summary, when you choose us as your supplier of Aluminum Coils in Germany, you can expect a comprehensive range of products, exceptional customer service, technical support, and access to the global expertise of CNBM. We are confident that we can meet all your Aluminum Coils requirements and contribute to the success of your projects. Contact us today to discuss your specific needs and let us be your trusted partner in aluminum procurement.