All Categories

- - Steel Wire Rod

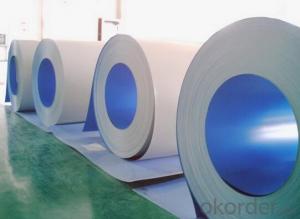

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

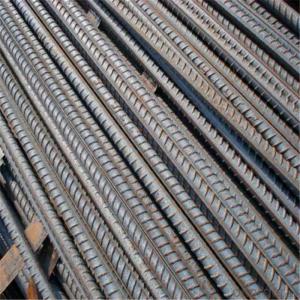

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can you explain the concept of nanostructured special steel and its benefits in materials science?

Nanostructured special steel is a type of steel that has been processed to have a specific microstructure on the nanoscale, typically with grain sizes less than 100 nanometers. This unique microstructure results in a range of enhanced properties compared to conventional steel. For instance, nanostructured special steel exhibits exceptional strength, hardness, and wear resistance, making it ideal for applications that require high performance and durability. Additionally, this type of steel often has improved corrosion resistance, thermal stability, and fatigue life. The benefits of nanostructured special steel in materials science are immense as it allows for the development of advanced materials that can be utilized in various industries such as automotive, aerospace, and energy, contributing to the development of more efficient and long-lasting products.

What defines special steel and sets it apart from other materials?

Special steel is defined by its unique composition and properties that make it distinct from other materials. It is characterized by its exceptional strength, durability, and corrosion resistance, which is achieved through specific alloying elements and precise manufacturing processes. Special steel is designed to meet specific requirements and applications, offering superior performance in industries such as automotive, aerospace, and construction. What sets it apart is its ability to withstand extreme conditions, provide high resistance to wear and tear, and maintain its structural integrity over time.

How is case hardening employed to enhance the surface properties of steel?

Case hardening is a process used to improve the surface properties of steel by introducing a hard layer on the surface while maintaining a relatively softer core. This is achieved by heating the steel in the presence of a carbon-rich compound, such as gas, liquid, or solid, and then rapidly cooling it. The carbon atoms diffuse into the surface of the steel, increasing its carbon content and making it harder. This hardened surface layer provides improved wear resistance, increased hardness, and enhanced durability to the steel, making it suitable for various applications in industries like automotive, aerospace, and machinery.

How are X-ray and ultrasonic testing employed in steel inspection?

X-ray and ultrasonic testing are commonly employed in steel inspection for non-destructive evaluation. X-ray testing uses electromagnetic radiation to penetrate the steel, creating an image that can detect internal flaws such as cracks, voids, or inclusions. Ultrasonic testing, on the other hand, uses high-frequency sound waves to detect defects by sending pulses through the steel and analyzing the reflected waves. Both methods are effective in identifying defects and ensuring the structural integrity of steel components.

Wholesale Special Steel from supplier in Germany

We are a Special Steel supplier serving the Germany, mainly engaged in the sale, quotation, and technical support services of various Special Steel products in the Germany region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Special Steel procurement services in the Germany. Not only do we have a wide range of Special Steel products, but after years of market development in the Germany, we can also provide valuable experience for your projects.