All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel pipes support the conveyance of chemicals in the petrochemical industry?

Steel pipes are widely used in the petrochemical industry due to their exceptional strength, durability, and resistance to corrosion. These pipes provide a reliable and safe means of transporting chemicals by effectively containing and supporting the conveyance process. The steel's high tensile strength allows the pipes to withstand the high pressure and temperature conditions encountered in petrochemical operations. Additionally, the smooth interior surface of steel pipes minimizes friction and ensures efficient flow, preventing any potential blockages or leaks during chemical transportation. Overall, steel pipes play a crucial role in supporting the conveyance of chemicals within the petrochemical industry, ensuring the safe and reliable transport of these substances.

What measures can be taken to prevent steel pipes from corroding in marine and offshore environments?

Several measures can be taken to prevent steel pipes from corroding in marine and offshore environments. Firstly, using corrosion-resistant alloys such as stainless steel or duplex stainless steel can significantly reduce the risk of corrosion. Additionally, applying protective coatings like epoxy or polyethylene can create a barrier between the steel and the corrosive environment. Regular inspection and maintenance, including cleaning and repainting, should also be carried out to identify and address any signs of corrosion at an early stage. Lastly, implementing cathodic protection systems, such as sacrificial anodes or impressed current systems, can help to protect steel pipes by diverting the corrosion process away from them.

What measures can be taken to prevent galvanized steel pipes from rusting?

There are several measures that can be taken to prevent galvanized steel pipes from rusting. Firstly, regular inspections and maintenance should be conducted to identify and address any signs of corrosion or damage. Secondly, applying a protective coating or paint to the surface of the pipes can provide an additional layer of defense against rust. Additionally, ensuring proper drainage and ventilation around the pipes can help prevent moisture accumulation, which is a major contributor to rust formation. Finally, using corrosion-resistant materials or alloys for fittings and connectors, and avoiding contact with corrosive substances, can further enhance the longevity of galvanized steel pipes.

What are the regulations and standards for steel pipe production and installation?

The regulations and standards for steel pipe production and installation can vary depending on the country and industry. However, some common regulations and standards include adhering to manufacturing specifications, such as ASTM A53 or API 5L, which outline the material properties, dimensions, and testing requirements for steel pipes. Additionally, installation standards, like those set by organizations such as the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO), provide guidelines for proper installation techniques, including welding procedures, inspection criteria, and safety measures. Compliance with these regulations and standards ensures the quality, safety, and performance of steel pipes in various applications.

Wholesale Steel Pipes from supplier in Luxembourg

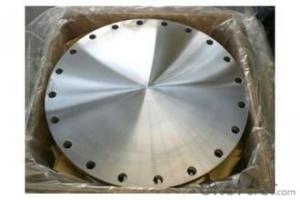

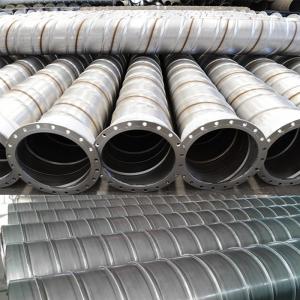

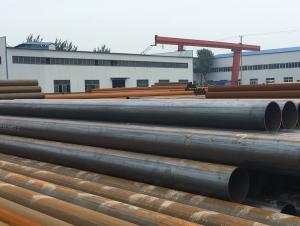

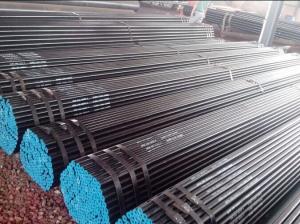

Our team of experts is committed to providing top-quality Steel Pipes products that meet international standards and specifications. We offer a wide range of Steel Pipes, including seamless pipes, welded pipes, galvanized pipes, and stainless steel pipes, suitable for various industries such as construction, oil and gas, water supply, and more.

In addition to our comprehensive product range, we also offer sales and quotation services to ensure you receive competitive pricing for your Steel Pipes requirements. Our dedicated sales team is available to assist you in selecting the right products for your projects and provide customized solutions to meet your specific needs.

Furthermore, we provide technical support services to help you with any technical queries or challenges you may encounter during the procurement process. Our team of engineers and technicians are well-equipped with the knowledge and expertise to assist you in finding the best solutions for your Steel Pipes requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have a strong global network and resources, allowing us to offer convenient one-stop procurement services in Luxembourg. Whether you need Steel Pipes for a small-scale project or a large-scale industrial project, we have the capability to fulfill your requirements efficiently and effectively.

We understand the importance of timely delivery and strive to ensure that your Steel Pipes products are delivered to your desired location on time. With our extensive market experience in Luxembourg, we have built strong relationships with reliable logistics partners to ensure smooth and hassle-free delivery of your orders.

At our company, we prioritize customer satisfaction and strive to exceed your expectations in terms of product quality, service, and support. Contact us today for all your Steel Pipes needs in Luxembourg, and let us be your trusted partner in your projects.

In addition to our comprehensive product range, we also offer sales and quotation services to ensure you receive competitive pricing for your Steel Pipes requirements. Our dedicated sales team is available to assist you in selecting the right products for your projects and provide customized solutions to meet your specific needs.

Furthermore, we provide technical support services to help you with any technical queries or challenges you may encounter during the procurement process. Our team of engineers and technicians are well-equipped with the knowledge and expertise to assist you in finding the best solutions for your Steel Pipes requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have a strong global network and resources, allowing us to offer convenient one-stop procurement services in Luxembourg. Whether you need Steel Pipes for a small-scale project or a large-scale industrial project, we have the capability to fulfill your requirements efficiently and effectively.

We understand the importance of timely delivery and strive to ensure that your Steel Pipes products are delivered to your desired location on time. With our extensive market experience in Luxembourg, we have built strong relationships with reliable logistics partners to ensure smooth and hassle-free delivery of your orders.

At our company, we prioritize customer satisfaction and strive to exceed your expectations in terms of product quality, service, and support. Contact us today for all your Steel Pipes needs in Luxembourg, and let us be your trusted partner in your projects.