All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

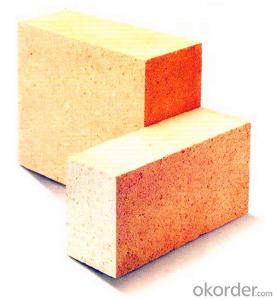

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can refractory bricks be used in kilns and ovens?

Yes, refractory bricks can be used in kilns and ovens. Refractory bricks are designed to withstand high temperatures and provide insulation, making them ideal for lining kilns and ovens where extreme heat is generated.

Can refractory bricks be recycled?

Yes, refractory bricks can be recycled. They can be crushed and used as aggregates in the production of new refractory materials or can be used as fillers in construction projects. Additionally, refractory bricks can also be melted down and used as raw materials for the manufacturing of new bricks.

Can refractory bricks be used for rotary coolers?

Yes, refractory bricks can be used for rotary coolers. Refractory bricks are designed to withstand high temperatures and provide insulation, making them suitable for applications such as rotary coolers where heat resistance and thermal insulation are required.

How do refractory bricks resist slag attack?

Refractory bricks resist slag attack through their high temperature resistance, chemical composition, and structural integrity. The bricks are made from materials that can withstand extreme heat, often including high amounts of alumina, magnesia, or silica. These materials have low reactivity with the slag, preventing it from chemically eroding or dissolving the bricks. Additionally, the bricks are designed with a dense and compact structure, reducing the permeability and penetration of the slag. This combination of high temperature resistance, chemical inertness, and structural integrity allows refractory bricks to effectively resist slag attack.

Can refractory bricks be used in the construction of boilers for oil refining?

Yes, refractory bricks can be used in the construction of boilers for oil refining. Refractory bricks are designed to withstand high temperatures and harsh conditions, making them suitable for the intense heat and corrosive environment of oil refining. They provide insulation and help maintain the structural integrity of the boiler, ensuring efficient and safe operation in the oil refining process.

Wholesale Refractory Bricks from supplier in Luxembourg

Our team of experts can assist you in selecting the right refractory bricks for your specific requirements, ensuring optimal performance and durability. We offer a wide range of refractory bricks, including fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and insulating bricks.

In addition to supplying refractory bricks, we also provide sales, quotation, and technical support services. Our dedicated sales team will work closely with you to understand your needs and provide competitive pricing for your projects. We strive to offer timely and accurate quotations to ensure a smooth procurement process.

Moreover, our technical support team is always available to provide guidance and assistance throughout your project. Whether you need advice on brick selection, installation techniques, or troubleshooting, we are here to help. Our experts have extensive knowledge and experience in the field of refractory materials, and we are committed to delivering high-quality support to our customers.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your refractory bricks procurement needs in Luxembourg. CNBM is a leading supplier of construction materials globally, and our affiliation with this prestigious company ensures that we can offer you reliable and top-notch products.

With our extensive experience in the Luxembourg market, we understand the unique requirements and challenges of local projects. We can provide valuable insights and expertise to help you achieve optimal results. Whether you are working on a small-scale residential project or a large industrial venture, we can tailor our solutions to meet your specific needs.

Contact us today to discuss your refractory bricks requirements in Luxembourg. We are committed to delivering exceptional products and services to our customers and look forward to partnering with you on your next project.

In addition to supplying refractory bricks, we also provide sales, quotation, and technical support services. Our dedicated sales team will work closely with you to understand your needs and provide competitive pricing for your projects. We strive to offer timely and accurate quotations to ensure a smooth procurement process.

Moreover, our technical support team is always available to provide guidance and assistance throughout your project. Whether you need advice on brick selection, installation techniques, or troubleshooting, we are here to help. Our experts have extensive knowledge and experience in the field of refractory materials, and we are committed to delivering high-quality support to our customers.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your refractory bricks procurement needs in Luxembourg. CNBM is a leading supplier of construction materials globally, and our affiliation with this prestigious company ensures that we can offer you reliable and top-notch products.

With our extensive experience in the Luxembourg market, we understand the unique requirements and challenges of local projects. We can provide valuable insights and expertise to help you achieve optimal results. Whether you are working on a small-scale residential project or a large industrial venture, we can tailor our solutions to meet your specific needs.

Contact us today to discuss your refractory bricks requirements in Luxembourg. We are committed to delivering exceptional products and services to our customers and look forward to partnering with you on your next project.

Hot Search

- Monolithic Refractories in Palau

- Ceramic Fiber Products in Hungary

- Refractory Bricks in Israel

- Raw Materials For Refractory in Turkmenistan

- Ceramic Fiber Products in Switzerland

- Raw Materials For Refractory in Malta

- Refractory Bricks in Guatemala

- Refractory Bricks in Argentina

- Ceramic Fiber Products in Indonesia

- Ceramic Fiber Products in Japan