All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

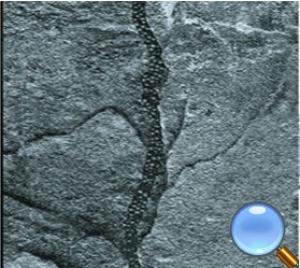

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining lead holding furnaces?

Yes, monolithic refractories can be used for lining lead holding furnaces. Monolithic refractories offer excellent resistance to high temperatures and chemical corrosion, making them suitable for lining lead holding furnaces where exposure to molten lead and its corrosive properties is a concern. Additionally, the flexibility of monolithic refractories allows for easy installation and repair.

Can monolithic refractories be used in contact with corrosive gases?

No, monolithic refractories should not be used in contact with corrosive gases as they are susceptible to chemical attack and may deteriorate or degrade over time.

What is the typical shelf life of monolithic refractories?

The typical shelf life of monolithic refractories can vary depending on various factors such as the specific composition of the refractory, storage conditions, and manufacturer recommendations. However, in general, monolithic refractories can have a shelf life of several months to a few years when stored properly in a dry and controlled environment. It is important to follow the manufacturer's guidelines and conduct regular inspections to ensure the quality and usability of the refractory before use.

Are monolithic refractories suitable for use in blast furnaces?

Yes, monolithic refractories are suitable for use in blast furnaces. Monolithic refractories are a type of refractory material that can be easily shaped and applied as a single, coherent mass, making them highly adaptable for lining the complex structures of blast furnaces. Monolithics exhibit excellent thermal stability, resistance to thermal shock, and high mechanical strength, which are crucial properties for withstanding the extreme temperatures and harsh conditions inside blast furnaces. Additionally, monolithic refractories offer advantages such as quick installation, reduced maintenance, and improved energy efficiency, making them a preferred choice for lining blast furnaces in various industries.

Can monolithic refractories be used in high-pressure applications?

Yes, monolithic refractories can be used in high-pressure applications. Monolithic refractories are designed to withstand extreme temperatures and pressures, making them suitable for various industrial processes, including those involving high-pressure conditions. These materials are often used in furnaces, boilers, and kilns, where they provide excellent thermal insulation and resistance to mechanical stress even under high-pressure environments.

Wholesale Monolithic Refractories from supplier in Palau

With our expertise in supplying Monolithic Refractories, we are able to offer you a wide range of products tailored to meet your specific needs in Palau. Whether you require high-quality castables, plastics, or ramming mixes, we have the right solutions for your refractory applications.

Our team of dedicated professionals is committed to providing you with exceptional sales and technical support services. We understand the importance of timely and accurate quotations, and we strive to deliver competitive prices for our products. Additionally, our technical experts are always available to assist you with any questions or concerns you may have regarding the selection and installation of refractory materials.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry knowledge. This allows us to efficiently source and deliver the products you need, ensuring a seamless procurement process. You can rely on us to meet your deadlines and provide reliable and efficient delivery services.

Our years of experience operating in Palau have given us a deep understanding of the local market. We are familiar with the unique challenges and requirements of projects in the region, and we can offer valuable insights to help you achieve success. Whether you are working on a large-scale industrial project or a smaller residential application, we have the expertise and resources to support you every step of the way.

Choose us as your trusted partner for Monolithic Refractories in Palau and experience the convenience and efficiency of our comprehensive sales, quoting, and technical support services. Contact us today to discuss your specific needs and let us assist you in finding the perfect solutions for your refractory requirements.

Our team of dedicated professionals is committed to providing you with exceptional sales and technical support services. We understand the importance of timely and accurate quotations, and we strive to deliver competitive prices for our products. Additionally, our technical experts are always available to assist you with any questions or concerns you may have regarding the selection and installation of refractory materials.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry knowledge. This allows us to efficiently source and deliver the products you need, ensuring a seamless procurement process. You can rely on us to meet your deadlines and provide reliable and efficient delivery services.

Our years of experience operating in Palau have given us a deep understanding of the local market. We are familiar with the unique challenges and requirements of projects in the region, and we can offer valuable insights to help you achieve success. Whether you are working on a large-scale industrial project or a smaller residential application, we have the expertise and resources to support you every step of the way.

Choose us as your trusted partner for Monolithic Refractories in Palau and experience the convenience and efficiency of our comprehensive sales, quoting, and technical support services. Contact us today to discuss your specific needs and let us assist you in finding the perfect solutions for your refractory requirements.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Mauritius

- Refractory Bricks in Venezuela

- Raw Materials For Refractory in Syria

- Raw Materials For Refractory in Mexico

- Raw Materials For Refractory in Kiribati

- Monolithic Refractories in Kenya

- Monolithic Refractories in Armenia

- Ceramic Fiber Products in Andorra

- Refractory Bricks in Latvia