All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Describe the properties of silica-alumina refractories.

Silica-alumina refractories are a type of refractory material that is composed of a mixture of silica (SiO2) and alumina (Al2O3). These refractories are known for their high thermal stability, excellent strength, and resistance to corrosion and erosion. They have a low coefficient of thermal expansion, meaning they can withstand high temperatures without cracking or breaking.

Silica-alumina refractories also have good chemical stability, making them suitable for use in various industries such as steel, cement, glass, and petrochemical. They can withstand chemical reactions and harsh environments, making them ideal for lining furnaces, kilns, and other high-temperature equipment.

Furthermore, silica-alumina refractories have good insulation properties, allowing them to retain heat and prevent heat loss. This helps in reducing energy consumption and improving overall efficiency.

Overall, the properties of silica-alumina refractories make them highly desirable for applications where high temperature resistance, chemical stability, and durability are required.

What are the properties of fused silica-based refractory materials?

Fused silica-based refractory materials have several key properties. They have high melting points, excellent thermal shock resistance, low thermal conductivity, and good chemical resistance. They are also non-porous, have high dimensional stability, and exhibit low expansion coefficients. These properties make them ideal for applications in high-temperature environments, such as in the glass, steel, and ceramic industries.

What are the refractory raw materials used in lining open hearth furnaces?

The refractory raw materials commonly used in lining open hearth furnaces include magnesite, dolomite, chromite, and alumina. These materials are chosen for their high heat resistance and ability to withstand the extreme temperatures and harsh conditions inside the furnace.

Wholesale Raw Materials For Refractory from supplier in Syria

Whether you are in need of high-quality raw materials for manufacturing refractory products or require assistance with technical aspects, our company is here to help. As a subsidiary of CNBM, a renowned Fortune Global 500 company, we have access to a vast network of resources and expertise.

Our team of professionals is dedicated to delivering exceptional services to our clients in Syria. We understand the importance of reliable and efficient supply chains, and our aim is to provide one-stop procurement solutions for raw materials for refractory products.

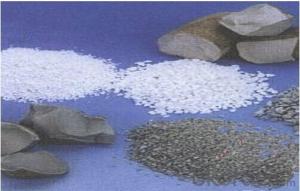

We offer a diverse range of raw materials, including but not limited to, alumina, silica, magnesia, and graphite. These materials are essential for producing high-performance refractory products that can withstand extreme temperatures and harsh conditions.

In addition to our product offerings, we also provide comprehensive sales and quotation services. Our experienced sales team is proficient in understanding your specific requirements and offering tailored solutions that meet your needs. We strive to provide competitive pricing without compromising on quality.

Furthermore, our technical support team is readily available to assist you throughout your projects. Whether you need guidance on material selection, product performance analysis, or troubleshooting, our experts are here to provide valuable insights and support. We aim to be your trusted partner in ensuring the success of your refractory projects.

With our extensive market experience and strong commitment to customer satisfaction, we are confident in our ability to meet and exceed your expectations. Contact us today to explore how we can assist you in sourcing raw materials for refractory products in Syria.

Our team of professionals is dedicated to delivering exceptional services to our clients in Syria. We understand the importance of reliable and efficient supply chains, and our aim is to provide one-stop procurement solutions for raw materials for refractory products.

We offer a diverse range of raw materials, including but not limited to, alumina, silica, magnesia, and graphite. These materials are essential for producing high-performance refractory products that can withstand extreme temperatures and harsh conditions.

In addition to our product offerings, we also provide comprehensive sales and quotation services. Our experienced sales team is proficient in understanding your specific requirements and offering tailored solutions that meet your needs. We strive to provide competitive pricing without compromising on quality.

Furthermore, our technical support team is readily available to assist you throughout your projects. Whether you need guidance on material selection, product performance analysis, or troubleshooting, our experts are here to provide valuable insights and support. We aim to be your trusted partner in ensuring the success of your refractory projects.

With our extensive market experience and strong commitment to customer satisfaction, we are confident in our ability to meet and exceed your expectations. Contact us today to explore how we can assist you in sourcing raw materials for refractory products in Syria.

Hot Search

- Monolithic Refractories in Pakistan

- Ceramic Fiber Products in Syria

- Refractory Bricks in Mali

- Raw Materials For Refractory in Qatar

- Refractory Bricks in Iraq

- Refractory Bricks in Kiribati

- Raw Materials For Refractory in Samoa

- Ceramic Fiber Products in Colombia

- Ceramic Fiber Products in Moldova

- Raw Materials For Refractory in Nauru