All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum grating for walkways?

The role of aluminum coils in the production of aluminum grating for walkways is to provide the raw material from which the grating is manufactured. The coils are processed, shaped, and cut to create the desired dimensions and patterns of the grating. The use of aluminum coils ensures that the grating is lightweight, corrosion-resistant, and durable, making it suitable for walkway applications.

What is the role of aluminum coils in the construction of lightweight structures?

The role of aluminum coils in the construction of lightweight structures is to provide a strong and durable material that is also lightweight. Aluminum coils are commonly used in the construction industry due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are often used in applications where weight reduction is a priority, such as in the construction of aircraft, automobiles, and buildings. The use of aluminum coils allows for the creation of lightweight structures that are both efficient and cost-effective.

What are the best practices for eliminating surface contaminants on aluminum coils?

The best practices for eliminating surface contaminants on aluminum coils typically involve a combination of mechanical cleaning, chemical cleaning, and rinsing processes. Mechanical cleaning methods such as brushing or scrubbing can be used to remove loose dirt or debris from the surface. Chemical cleaning involves the use of specific solvents or cleaners that are designed to dissolve or dislodge stubborn contaminants like oils, greases, or corrosion. The coils should then be thoroughly rinsed with water to remove any remaining residue. Regular and consistent cleaning maintenance is essential to ensure optimal performance and longevity of the aluminum coils.

How do you store aluminum coils to prevent damage?

To prevent damage to aluminum coils, it is recommended to store them in a dry and well-ventilated area, away from moisture and direct sunlight. They should be kept on a flat surface or properly supported to avoid bending or warping. Additionally, using protective covers or wrapping the coils in plastic can provide an extra layer of safeguarding against scratches or dents.

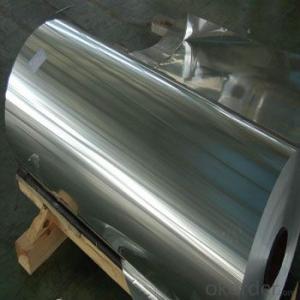

Wholesale Aluminum Coils from supplier in Syria

We understand the unique challenges and requirements of the Syrian market and are committed to delivering high-quality Aluminum Coils that meet international standards. Our team of experienced professionals is dedicated to providing exceptional customer service, ensuring timely delivery and competitive pricing.

Whether you require Aluminum Coils for construction, automotive, or other industries, we have a wide range of options to cater to your specific requirements. Our products are known for their durability, corrosion resistance, and excellent thermal conductivity, making them ideal for various applications.

In addition to our extensive product range, we also offer comprehensive technical support to assist you in selecting the right Aluminum Coils for your projects. Our knowledgeable team can provide guidance on product specifications, installation techniques, and maintenance procedures, ensuring optimal performance and longevity.

As a subsidiary of CNBM, a Fortune Global 500 company with a strong presence in the global aluminum industry, we have access to advanced manufacturing technologies and a vast network of suppliers. This enables us to offer competitive prices without compromising on quality.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and reliability. We are committed to exceeding your expectations in terms of product quality, customer service, and overall value.

Contact us today to discuss your Aluminum Coils requirements in Syria and experience the difference of working with a leading supplier backed by years of expertise and a global reputation for excellence.

Whether you require Aluminum Coils for construction, automotive, or other industries, we have a wide range of options to cater to your specific requirements. Our products are known for their durability, corrosion resistance, and excellent thermal conductivity, making them ideal for various applications.

In addition to our extensive product range, we also offer comprehensive technical support to assist you in selecting the right Aluminum Coils for your projects. Our knowledgeable team can provide guidance on product specifications, installation techniques, and maintenance procedures, ensuring optimal performance and longevity.

As a subsidiary of CNBM, a Fortune Global 500 company with a strong presence in the global aluminum industry, we have access to advanced manufacturing technologies and a vast network of suppliers. This enables us to offer competitive prices without compromising on quality.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships based on trust and reliability. We are committed to exceeding your expectations in terms of product quality, customer service, and overall value.

Contact us today to discuss your Aluminum Coils requirements in Syria and experience the difference of working with a leading supplier backed by years of expertise and a global reputation for excellence.